Most parcels leave the pack station without accurate dimensions recorded. A shipping label gets printed, the box is sealed, and the shipment goes out. The real dimensions often come into play only when the carrier scans the parcel, and that is when surprises happen.

If your numbers do not match the carrier’s, the difference shows up as a chargeback or a billing dispute. It can also cause delays when shipments are flagged for recheck. For shippers moving hundreds or thousands of boxes, even small errors can turn into lost margin and frustrated customers.

This guide is about solving that gap. We will look at why shippers need dimensional measuring systems, how they differ from basic dimensional measurement tools like tape measures, and how they fit into parcel shipping to make the process more accurate and reliable.

How can one wrong inch raise your shipping costs?

One extra inch changes the cubic volume, which changes the billed weight, and that can move a parcel into a more expensive bracket. That is when the penalties start to show up.

- Recorded: 18 × 18 × 18 in

Volume: 5,832 in³. With a DIM divisor of 139, the DIM weight is 41.96 lb. Most carriers round up, so you pay for 42 lb.

- Actual: 19 × 18 × 18 in

Volume: 6,156 in³. DIM weight is 44.30 lb. Rounded, you pay for 45 lb.

That single inch adds 3 lb of billed weight. If the zone rate steps up from $1.20 to $1.80 per pound at that bracket, you are paying several dollars more per parcel. That might not feel big on one label, but across 1,000 labels a week, it quietly adds up to five figures a quarter.

The hidden costs you feel later

- Lower trailer utilization, which means paying for more trucks than you need

- Slower claim resolution when your records do not match the carrier’s

- Extra labor spent on re-measuring, repacking, and explaining disputes

The damage is not obvious on the first day. It builds over time. That is why many teams move from manual tools to dimensional measuring systems. The purpose is not to buy fancy equipment. The purpose is to stop paying for the inch that slips past unnoticed.

Why can’t manual dimensional measurement tools keep up with parcel shipping needs?

Manual dimensional measurement tools like tape measures, rulers, or calipers are still common in many shipping rooms. They are cheap, easy to find, and familiar. For low volume they can work. But parcel operations that handle hundreds or thousands of boxes a day see the limits quickly.

Measurement errors: A tape pulled at the wrong angle adds half an inch. A worker rounding down saves time but creates false data. Even a simple mistake like swapping length and width can trigger higher shipping charges. Carriers always measure again on their own equipment, and when numbers do not match, a surcharge arrives.

Time-Consuming process: Measuring one box by hand takes 15 to 20 seconds if done carefully. Writing or typing the dimensions into a system adds another 10 seconds. That is half a minute for one parcel. At 500 parcels a day, more than four hours vanish on just measuring. Multiply by a week or a month and the wasted labor is clear.

Inconsistent results: Ten workers can measure the same carton and come back with ten slightly different results. One rounds up, other rounds down, another measures with the tape pressed too tightly. The carrier’s scan is the only version that matters, which means internal records often carry no weight in a dispute.

Hidden costs: Manual tools look cheap at purchase but expensive in use. Lost labor hours, rework, and repeated disputes all eat into margins. A simple mismeasurement can make a low-margin parcel unprofitable after one surcharge.

That is why manual dimensional measurement tools fail at parcel scale. They slow teams down, create errors, and delays parcel processing. Automated dimensional measuring systems are built to solve these gaps by capturing the accurate dimensions instantly and feeding them directly into your WMS or shipping software.

What are dimensional measuring systems?

A dimensional measuring system is an automated device or equipment that captures the length, width, and height of parcels, polybags, cubes, cuboids and irregulars in less than a second. Most systems like vMeasure also record weight and images in the same process. Instead of relying on a person with a tape measure, the system scans the parcel in seconds and pushes the data directly into the warehouse or shipping software.

These systems differ from basic tools. A tape measure only gives numbers. The dimensional measurement systems give verified data with repeatability, and digital records that carriers cannot easily dispute. That is why they are becoming standard in parcel shipping, especially where volume is high.

For parcel shippers, dimensional measuring systems are not just tools for getting size and weight. They are a safeguard against extra carrier fees, a way to keep shipping data clean, and a step toward full automation in the warehouse.

How do dimensional measuring systems work?

The process looks simple on the surface but powered by precise technology.

A warehouse employee places the parcel on the automated dimensional measuring systems’ platform or on the conveyor.

3D Sensors or computer vision-based cameras capture the parcel’s length, width, and height in seconds.

Many systems have an integrated weight scale. As the box is measured, weight is recorded at the same time. This eliminates the need for a second step on a separate weighing station.

The dimensional measuring system instantly transfers the measurements to your existing WMS, OMS, TMS or shipping software via no-code API and webhooks. No typing, no rechecking.

Advanced dimensional measurement systems like vMeasure, also capture a timestamped image of the parcel. This record can be used later to resolve disputes with carriers or customers.

In practice, this workflow means a worker can measure and process a parcel in under two seconds instead of half a minute. Multiply that across hundreds of parcels and the savings in both labor and cost are clear.

The technology does not just speed up work. It builds consistency. Every parcel is measured the same way, every time, regardless of who is working at the station. That consistency is what keeps correction fees and disputes from piling up.

What types of dimensional measuring systems are available in the market?

Parcel shippers and freight handlers do not all need the same setup. Some process a few boxes an hour. Others move thousands a day. Dimensional measuring systems come in several forms to match these very different needs like:

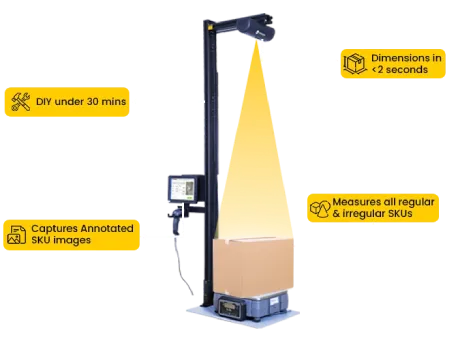

1. Static Parcel Dimensioning Systems

Static dimensional measuring systems are compact setups used at packing stations. A worker places a parcel under the scanner, and the system records length, width, height, and often weight. These are well-suited for e-commerce shippers and 3PLs handling medium order volumes.

They offer a balance of cost and control. One operator can process orders without guesswork, and every parcel is measured consistently before it leaves the floor.

2. Pallet Dimensioning Systems

Pallet systems measure freight and overhangs. Instead of scanning individual parcels, they capture the dimensions of a fully palletized shipment. These systems are common in LTL shipping, distribution centers, and cross-dock facilities where pallets move directly onto trailers

They help carriers and shippers calculate density, confirm NMFC classifications, and reduce the risk of reclass disputes. Many 3PLs and warehouses that manage both parcels and freight use pallet dimensioners alongside parcel systems to cover all shipment types.

3. Conveyor-Based Parcel Dimensioning Systems

Conveyor systems are built for speed. Parcels move down a conveyor belt, and the system measures them automatically as they pass. Dimensions, weight, barcodes and even images are captured in motion.

These conveyor-based dimensional measuring systems fit high-volume operations like fulfillment centers or carrier terminals where throughput is critical. They often tie into sortation lines, letting warehouses measure, weigh, and route parcels in one continuous flow.

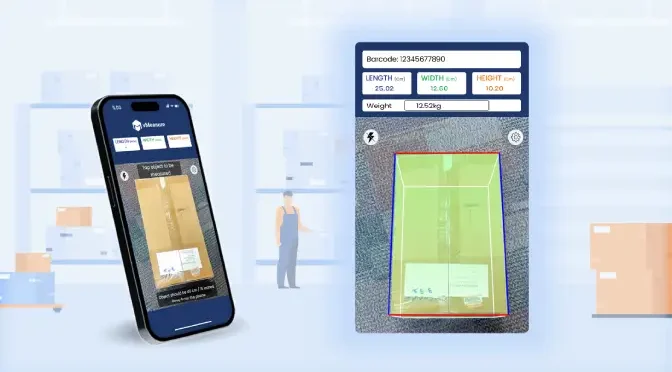

4. Mobile or Handheld Dimensioning Tools

Mobile systems,

such as iOS applications, turn an iPhone into a handheld scanner. Carriers and couriers often use these dimensional measuring apps in field operations like pickup and delivery to ensure instant parcel verification.

What are the benefits of using dimensional measurement systems?

Dimensional measuring systems do more than speed up a process. They solve problems that directly affect cost, compliance, and customer experience. Here are the main benefits.

Accurate billing: Carriers charge by dimensional weight, not just actual weight. These systems ensure your records match theirs. That means fewer chargebacks, fewer disputes, and cleaner invoices.

Faster processing: Manual measuring takes half a minute per parcel. This system does it in seconds. In high-volume shipping, the time saved per box adds up to hours saved each day.

Consistent results: Measurements are the same regardless of who is working at the station. This builds carriers trust and gives teams reliable data to work with.

Lower labor costs: Automated dimension capture reduces the need for workers to spend time measuring, rechecking, and typing numbers into a system. Staff can focus on packing, loading, and other tasks that move shipments forward.

Software integration: Measurements flow directly into your existing WMS, TMS, or carrier software. That removes manual entry errors and creates a real-time view of shipping costs and trends.

Customer confidence: Images and accurate dimensions give a record that can be shared if a customer disputes a shipment. Having proof on file reduces back-and-forth and shows professionalism.

How to choose the right dimensional measuring system?

- Low to medium: A static station can handle hundreds of parcels a day at the packing bench.

- High volume: Conveyor-based dimensional measuring systems process thousands of parcels per hour with little human input.

- Consider the mix of parcels you handle. Regular cartons, polybags, and even odd-shaped irregulars or bulky items can all be measured with a single dimensional measuring system, such as vMeasure, which offers adjustable mount heights.

- Limited space: Compact static stations or mobile devices are the practical choice.

- Larger facilities: Conveyor systems make sense if you have the floor space to dedicate to automation.

Integration needs:

- Check if the system connects to your WMS, TMS, or shipping software. Without integration, you risk replacing manual measuring with manual data entry, which defeats the purpose.

Accuracy requirements:

- Most parcel dimensional measuring systems within ±0.2 inches. For high-value shipments or strict carrier contracts, that level of precision makes a difference.

Budget and ROI:

- Entry-level static systems are affordable and pay back quickly for small shippers.

- Conveyor systems cost more up front but save far more in labor and correction fees once volume is high.

Parcel shipping leaves little room for mistakes. A wrong number on a label can trigger higher carrier charges, wasted labor, and disputes that take time to settle. Manual tools make those mistakes more likely because they rely on speed, judgment, and repetition from workers who already have a dozen other tasks.

Dimensional measuring systems fix that by taking the guesswork out of the process. They capture accurate dimensions in seconds, send data straight to your systems, and create digital proof that can stand up in a carrier audit. The result is fewer correction fees, faster order processing, and cleaner shipping data across the board.

The bottom line is simple. Every parcel has a cost attached to its dimensions. Get them right with a reliable dimensional measuring system, and you protect your margins, your carrier relationships, and your customer trust.

Frequently asked questions