The Ultimate Guide

To Automated Dimensioners

The logistics industry is always under insurmountable pressure because of customer expectations. With 60% of customers saying same-day or next-day delivery having significant influence on their purchase decision, the need for speed is perpetually increasing. However, the logistics industry is able to keep up and satisfy customer’s fast shipping demands through an array of modern solutions. An automated dimensioner is one of them.

The robust dimensioning system has simplified shipping and removed the irrationality behind charging less for the actual weight of a full truckload of feathers and more for a truckload of bricks.

Table of Contents

What is an automated dimensioner and how does it work?

Automated dimensioning systems became popular in the year 2015 with the introduction of DIM pricing.

There are many types of dimensioner based on their mode of operation such as laser-based dimensioners, computer-vision based dimensioners, and infrared dimensioning systems.

Automated dimensioning systems became popular in the year 2015 with the introduction of DIM pricing.

Though they differ in their methods, they essentially collect the same information known as product dimensions.

The DIM pricing requires the product of height, length, and width of an item which is then divided by a DIM divisor specific to each carrier.

An automated dimensioner instantly calculates product dimensions and weight using the technology it was built upon.

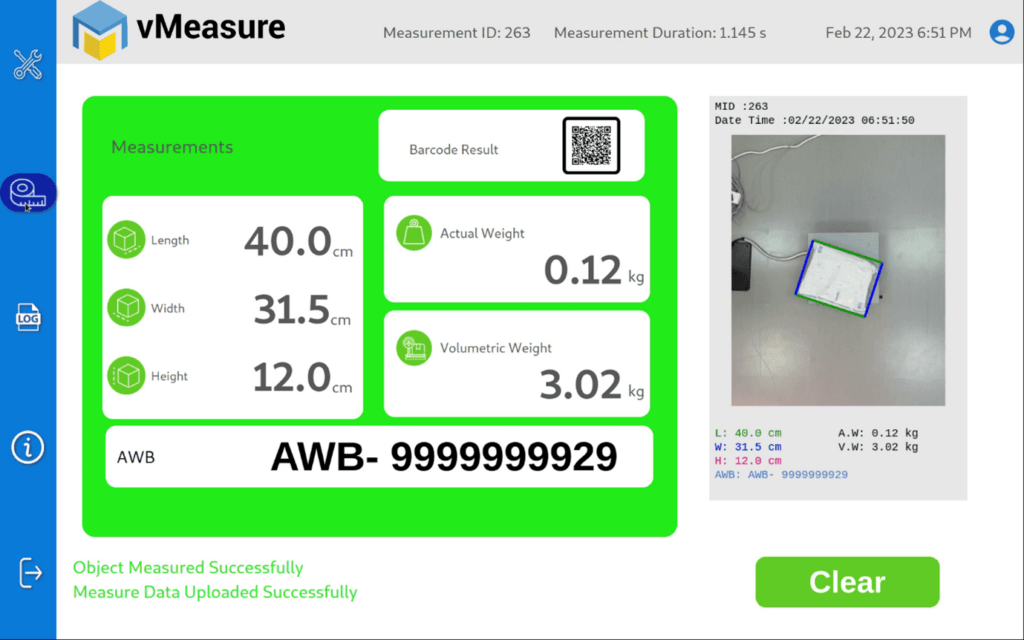

For instance, vMeasure Parcel Ultima is a computer-vision based dimensioner that gives accurate DIMs in <1 second.

The camera looks down from a specific height upon the object placed beneath it. Taking the bare ground or the base of the weighing scale as the reference point, it calculates the longest side on each point and renders the product dimensions along with the actual weight and volumetric weight.

Benefits of using an automated dimensioning system

Ever since automated dimensioners took over the logistics industry, it has been smooth sailing for every player in the industry. However, many warehouses still inadvertently use manual dimensioning process and do not realize the multi-fold benefits of using an automation. check out dimensional weighing systems

Increased productivity

Reduced shipping costs

Improved warehouse space utilization

Efficient Slotting

Optimized packaging

Truckload capacity planning

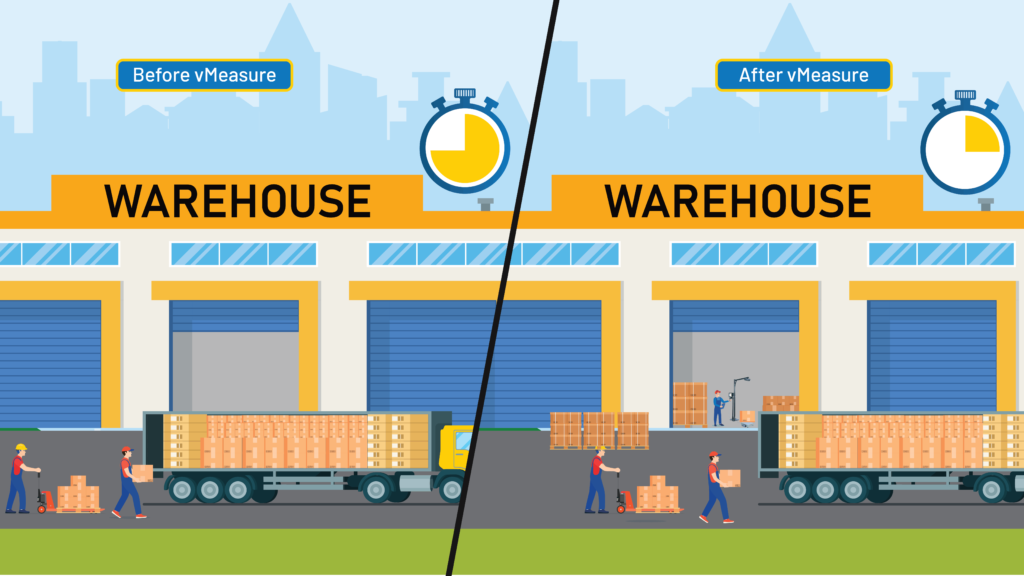

Increased Productivity

Manual dimensioning process is full of surprises and it’s not the kind anyone would like. It is slow, riddled with errors, and full of doubts. The complexity of dimensioning increases when an irregular SKU presents itself to the worker.

On the other side, an automated dimensioning machine captures accurate measurements within seconds. It removes the redundancies and errors in dimensioning. Additionally, there is no need for the warehouse worker to manually enter SKU information into the WMS as the automated dimensioner pushes it from them.

This will automate the warehouse and move the workers to high-value activities.

For instance, vMeasure reduced the time taken for bill reconciliations from 7 days to 20 minutes for one of our customers. Check out the full case study here.

Reduced shipping costs

Shippers will have the power to negotiate better terms and rates with their carriers using automated dimensioning because of reliable measurements. Carriers will be in a nonchalant mood to give shippers amicable terms that way.

Statistics show that companies that has implemented automated dimensioners have reported savings of up to 30% on their shipping costs.

It gives shippers the required data to select the best mode of transportation and conform to all regional weight restrictions, thus reducing the chances of paying penalties or surcharges.

All thanks to the accuracy of automated dimensioners!

Improved warehouse space utilization

Every square foot in the warehouse is money. Imagine how good would it be to reduce the amount of space required by 20% and store more inventory.

A warehouse manager can optimize warehouse layout by analysing the wealth of SKU master data obtained through automated dimensioning. It will help make crucial warehouse equipment design and layout decisions to accommodate the varieties of SKU coming in and going out of the warehouse.

Efficient Slotting

A warehouse with limited space but better slotting would perform exceptionally well than a warehouse with a billion square feet but inefficiently managed.

Slotting maximizes the available space by placing SKUs in its most appropriate place. For instance, smaller items go to tighter spaces while large items go to lower shelves with open space. This will reduce the risk of SKU damage, misplacement, or loss.

Accurate dimensions inform the warehouse slotting mechanism about the SKU and therefore, become instrumental in finding its rightful place at the warehouse shelf.

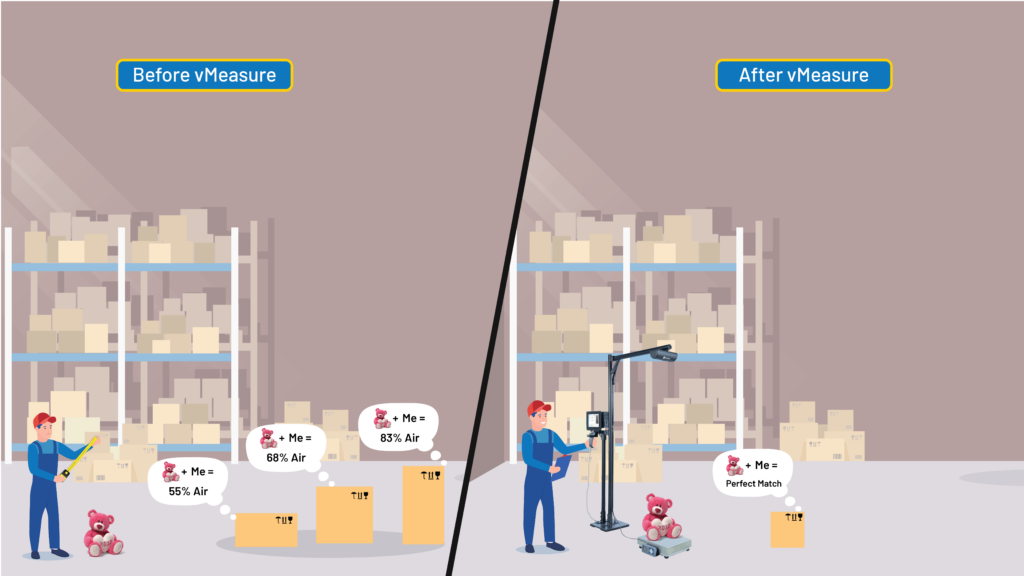

Optimized Packaging

The internet is full of images showing small objects in oversized parcels. It shows dissatisfied customers can instantly bring down the company’s reputation with a post. Hence, packaging plays an important role in customer satisfaction. Additionally, shippers pay for air while transporting orders in large boxes, not to mention the high probability of damage resulting from product movement inside the box.

With accurate dimensions, it takes less time in achieving zero air packaging by selecting the right carton box. A warehouse can easily reduce its packing waste by 60% through optimizing package using accurate dimensions.

Truckload capacity planning

Overloading a truck by just 10% decreases the fuel efficiency of the truck by 12%, leading to higher fuel expenses and mileage. That’s where an automated dimensioning system comes in handy.

Accurate dimensions of the shipment will help shippers plan a truckload in advance and maximise the truck’s loading capacity. Moreover, shippers can conform to the weight restrictions in the region and save themselves from paying hefty penalties.

Who needs an automated dimensioner and why?

The use cases for an automated dimensioner differs from industry to industry. While the core of capturing package dimensions remains the same, the way the information is utilized is unique to a company.

Typically, the following industries would need a dimensioner:

Warehouses

A warehouse’s use cases for the inbound process will be different than the use cases for the outbound process.

However, here are the reasons why a warehouse needs an automated dimensioner:

- Warehouse space optimization.

- Improve labour utilization.

- Automate data capture and transfer.

- Improve slotting and put away.

- Efficient picking and packing.

- Verify inbound and outbound SKU quality.

- Prevent SKU damage.

eCommerce Order fulfillment centers

An order fulfilment center handles a large volume of orders and there are a lot of moving parts at play. Therefore, an automated dimensioner help them:

- Increase productivity at the packing station.

- Handle high volumes of order.

- Improve carrier negotiation.

- Protect against damage claims.

- Increase order dispatch accuracy.

- Improve throughput rate.

- Handle a wide variety of SKU shape and size.

- Enhance picking and packing speed.

- Improved quality control.

Carriers

A carrier’s network is bound to head towards inefficiency in the absence of accurate dimensions because it is prevalent in its chain. Carriers will need a dimensioning system to:

- Optimize packaging.

- Plan delivery routes.

- Optimize loading time.

- Maximize truck’s capacity and improve load balancing.

- Improve freight billing accuracy.

- Eliminate rebills and reweighs.

- Improve data transparency with shippers.

- Comply with weight regulations.

Shippers

A shipper’s reputation hinges on the fact that items reach within the promised delivery window and without any damages. Here are reasons why a shipper will be looking to invest in an automated dimensioner:

- Determine right packing for the order.

- Provide accurate dimensions to the carrier.

- Negotiate better deals and rates.

- Reduce shipping charges.

- Decrease time spent on billing disputes.

- Improve revenue recovery.

- Enhance packaging.

- Increase parcel throughput.

What should you look for while buying a dimensioner?

The purchase of an automated dimensioner need not be very complex. Any operations manager should ask three simple questions and the answers will lead them to the right dimensioner.

What should you look for while buying a dimensioner?

Every dimensioner will support integrations with Warehouse Management System (WMS), Transport Management System (TMS), Multi-carrier shipping solutions (MCSS), and Order Management System (OMS).

However, the amount of time and effort required from the company’s IT team should factor into deciding the best dimensioner in this regard.

How accurate are the measurements?

Accuracy is key to level up in the dimensioning game. The level of accuracy provided will differ based on the tech used in the dimensioner and it is best to compare the data across multiple dimensioning technologies. However, an operations manager should keep in mind the trade-offs associated with capabilities and accuracy levels.

What is the use-case?

It is crucial to decide on the use case before even sifting through top dimensioner brands. Does the business handle small parcels or large ones? What is the minimum and maximum dimensions of the parcels? Formulating a specific use case will facilitate the selection of a fitting dimensioner.

How CV-based dimensioners differ from laser-based dimensioners?

The logistics industry derives the product dimensions from dimensioners. However, there are more than one technology available in the market, each with their own pros and cons.

Two popular technologies are Computer Vision dimensioners and Laser-based dimensioners.

Even though laser-based dimensioners outweigh CV-based dimensioners on accuracy and speed, there are other compelling reasons to choose computer vision technology.

What is the use-case?

The best part about CV technology is its simplicity. The dimensioner comes with multiple cameras and a software application. It can be installed and taken into production with minimal time and technical knowledge. For instance, the vMeasure Parcel Ultima can go live within 20 minutes of installation as it has less installation components.

On the other hand, laser-based dimensioners need elaborate effort and time to set up and calibrate as they require precise positioning of laser. Sometimes they will need adjustments to account for lighting and ambience changes.

Versatility

Computer vision based dimensioners can dimension many SKU shapes including irregulars better than laser-based dimensioning. This is because computer vision-based algorithms measure the products by calculating their longest dimension on all sides by directly looking down on the object.

Dimension all types of SKU in <1 Sec

with vMeasure Ultima Dimensioner

Integration capabilities

While both the technologies provide integration capabilities, CV-based dimensioners allows for more customization and flexibility. Therefore, this will be feasible for the operations manager to tailor-make the dimensioner to fit the company’s unique dimensioning workflow.

Look at vMeasure’s integration with ShipStation for an OEM manufacturer and wholesale distributor in the case study.

Use Cases

Understanding the technology is one thing and realizing the numerous ways in which it can be deployed is another. The intent for using a dimensioner must be clear to derive the best value out of it.

In the logistics industry, the use cases for an automated dimensioner are divided into Inbound use cases and Outbound use cases. Depending on where the dimensioning system is deployed, the systems it interacts with and the purpose for those interactions will change.

Inbound Use Cases

The dimensioning device will be deployed at the receiving station or the unloading dock in this use case.

Typically, the dimensions acquired in this stage will be utilized for:

- warehouse space optimization

- Cartonization

- SKU Master Data

- Slotting and Putaway

Outbound Use Cases

The dimensioner will be deployed at the loading dock or the shipping station for the following purposes:

- Maximizing truck capacity

- Accurate dimensions for carrier billing

- SKU image capture for parcel insurance

- Zero-air packaging

Start Dimensioning!

Getting the right dimensioner for your company is the key to unlocking tremendous value in the form of reduction in shipping costs, improvement in warehouse space utilization, and most importantly, fulfillment of sustainable goals.

No company will be shipping and paying for air in their packages. And no customer will be taking down a company on social media for sending their little airpods in a carton box meant for a travel bag.

That’s just one of the many values an automated dimensioning system will provide to your company and the world at large.

So, start dimensioning anything from an envelope to a refrigerator in <1 second with vMeasure. That too, for the price of a coffee/day.