Table of Contents

Summary

You are constantly seeking ways to simplify your business processes and cut costs as an owner of an eCommerce company. Automated dimensioning systems can be implemented in your warehouse as a means of doing this. These devices correctly assess the size and weight of parcels using cutting-edge technology, including lasers, sensors, and computer vision, from which it is possible to identify the most economical shipping option and rate.

Learn how automated dimensioning systems assist warehouses in minimizing unnecessary costs and adjusting pricing strategies to offset the cost by reading this blog post.

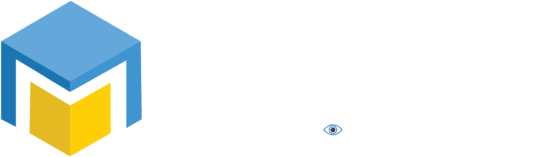

Impact of automated dimensioning systems in the warehouse

Automated dimensioning systems are revolutionizing warehouse packaging measurement and storage. These systems can increase efficiency, lower shipping and storage costs, and improve customer satisfaction by precisely measuring dimensions using sensors and other technologies. These solutions are a valuable resource for warehouses trying to streamline their processes and maintain an edge in a market that is becoming increasingly competitive. Therefore, automated dimensioning systems have a highly favorable effect on warehouse performance and contribute to it.

How can installing automated dimensioning systems help warehouses reduce costs and optimize pricing strategies?

Today the warehouses are overwhelmed by the constant influx of packages, and the manual measurement process slowed them down. The firm knows investing in automated dimensioning systems can make a huge difference in warehouse operations. These systems can revolutionize their operations by accurately measuring each package, helping them determine the best size and weight for shipping and storage. This optimization of space and resources allowed them to save time and money by avoiding the need for additional storage and transportation. The automated dimensioning systems truly transformed the warehouse, streamlining its processes and improving efficiency.

The impact on warehouse costs- Reduced shipping costs and Reduced labor costs

In the logistics and supply chain of every firm, warehouses are essential. They offer a central location for product storage and distribution and ensure that orders are delivered quickly and accurately to clients. However, running a warehouse may also be a big financial burden for a business due to the price of shipping, labor, and other factors.

Reducing shipping costs is one method of lowering warehouse costs. This can be accomplished through various tactics, including negotiating better rates with carriers, establishing a more efficient warehouse layout, or using more effective shipping methods. For instance, a company can reduce the cost of carrying items to and from the warehouse by negotiating lower prices with carriers or using a more effective transportation technique. Similar to how picking, packing, and shipping orders can take less time and effort when the warehouse architecture is optimized, this can also save money.

Cutting labor expenditures is a different strategy for lowering warehousing costs. This can be accomplished through various techniques, including automating work, implementing more effective procedures, or outsourcing some duties. For instance, reducing the requirement for human labor and associated cost savings can be achieved by deploying robots or automated systems to handle operations like picking and packing orders. Similar to how simplifying procedures and outsourcing certain tasks like order fulfillment or customer support may help a business run more effectively and spend less on employees.

The impact on pricing strategies- Optimizing shipping rates centering DIMs and weight and Adjusting pricing strategies to cover the cost

Automated dimensioning systems can impact pricing strategies by helping companies to more precisely determine shipping prices based on the size and weight of shipments. This can assist companies in avoiding shipping overcharging or undercharging, which can significantly influence their profitability. Additionally, by employing automated dimensioning systems, businesses may more precisely estimate the shipping costs associated with a certain product and set their prices accordingly, guaranteeing that they will cover their shipping expenses while simultaneously providing competitive rates to their clients.

Automated dimensioning systems can also impact pricing strategies by enabling companies to modify their price plans to cover costs. For instance, a company may need to change its pricing if it routinely loses money on shipping due to incorrect dimensioning. Businesses may discover places where they are losing money on shipping by using automated dimensioning systems, and then they can change their pricing to make sure that they are paying their costs and being profitable.

Conclusion

In conclusion, an automated dimensioning system in warehouses has the potential to lower costs significantly and enhance pricing tactics. Warehouses can save time and money and eliminate human error by automating measuring and recording product dimensions. Additionally, warehouses may be able to price their goods and services more properly because of automated dimensioning’s accuracy and efficiency, which could boost their profitability and marketability. In the end, automated dimensioning has a very favorable effect on warehouse expenses and pricing strategies, and it is expected that an increasing number of warehouses will adopt this technology in the future.