Summary

- Warehouse, logistics, and supply chains industries have become increasingly reliant on artificial intelligence (AI), computer vision, and edge computing technologies

- The warehouse embraces technology to revamp the operation entirely by automating the processes to optimize the supply chain and decrease order fulfillment expenses.

- To automate warehouse operations, you need a deeper understanding of the process flow and technology best suited to your business vertical.

- eCommerce businesses can deploy automated package dimensioners to the workspace to increase warehouse productivity by up to 17 percent.

Customer persona

- Logistics Specialist: sketch and optimize flexible transportation, logistics, warehouse, and customer services by understanding the latest warehouse technology trends.

- Operations Specialist: determines the storage requirements to manage various processes like inventory management, shipping, and evaluating policies and procedures to improve the warehouse operations using automation.

- Business Strategist: take responsibility for developing various strategic plans to reach the organizations’ goals and targets. Also, analyzes the existing operational strategies to improve profitability in the warehouse.

- Warehouse automation manager: maintains the statistical and financial records, ensures the quality and deliveries, and understand the latest technologies to optimize the working pattern in the warehouse.

Deploying package dimensioners in the warehouse

Therefore, package dimensioners must be deployed in warehouses and order fulfillment centers to quickly calibrate product dimensions and weight information to eliminate these dimensional problems. By eliminating manual dimensioning with the automated package dimensioners, you can mitigate dimensional errors, unnecessary shipping tariffs, improve pick-pack efficiency and in-house productivity.

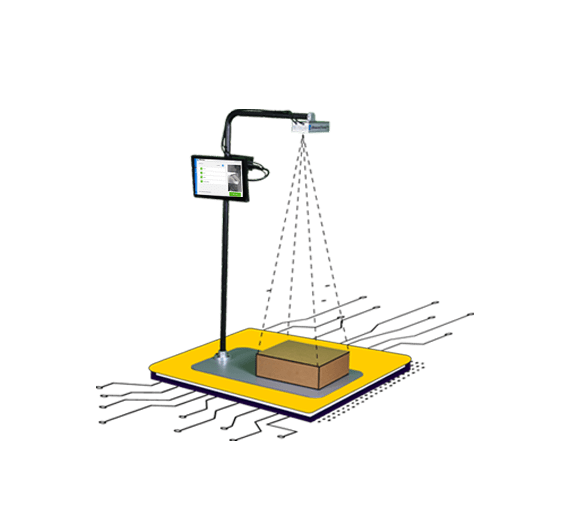

- Systems utilized to measure freights and pallet loads – Automated package dimensioning system.

- Systems used to measure parcels or individual boxes – Automated parcel dimensioning system.

Automated package dimensioner system

Automated Parcel dimensioning system

Automated Parcel dimensioning systems, or parcel dimensioners, are now present in both static and in-line types. The static dimensioning method is a “semi-automated” approach. An operator puts a parcel or object on the dimensioning system, and then the system calculates (and also weighs) the parcel. The machinery may be stationary or mounted on a cart and wheeled around the distribution center.

Static Vs. In-Motion Dimensioners