Summary

When you introduce a new piece of software or equipment to your workplace, there’s a considerable risk of employee dissatisfaction, bewilderment, and even resistance to the new solution.

However, if staff are comfortable with the technology adoption, production visibility will increase faster than predicted.

In light of this, deploying automated package dimensioners integrated with warehouse management systems (WMS) can significantly reduce dimensional errors and increase warehouse productivity.

With this in mind, the following blog will help you choose a package dimensioner for your warehouse by laying out eight essential considerations.

Written for:

- Warehouse Automation Manager:

Maintains the statistical and financial records, ensures consistency and dispatches and understands the modern technologies to uplift the warehouse’s operational efficiency.

- Operations Specialist:

Determines the storage needs for different processes such as delivery, policy and protocol evaluation, and inventory control to improve warehouse operations by automation.

- Business Strategist:

Take responsibility for thriving various strategic plans to meet the organizations’ objectives. Also, it explores the existing operational strategies to accelerate profitability in the warehouse.

- Logistics Specialist:

Using current warehouse infrastructure patterns, sketch and refine scalable transportation, logistics, inventory, and customer services.

Evolution Of Warehouses In E-Commerce

When shoppers gradually buy products online, eCommerce converts warehouses and distribution centers into future retail stores. According to recent estimates, the online shopping market share will hit the mid-teens in the next decade, up from less than 10% currently. The new buzz in e-commerce is the race to build successful last-mile distribution plans, which would be heavily influenced by the retailer’s perception of potential shipment cost and speed trade-offs—having that in mind, the warehouse and distribution centers should adopt automated package dimensioners to complete the last-mile delivery successfully.

So, how do you pick a package dimensioner that’s ideal for your vertical? To do so, you must first understand the criteria and features of a robust package dimensioner.

Choosing The Right Automated Package Dimensioner For Your Warehouse

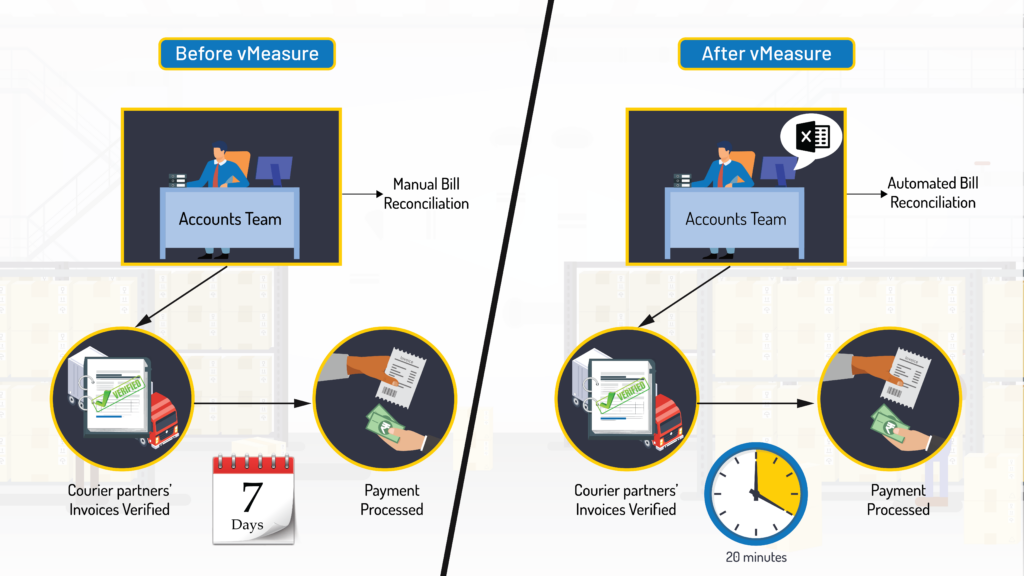

eCommerce warehouse owners and shippers use automated package dimensioners to automate the pallet measurement and documentation process, which previously consisted of measuring packages with a tape measure, photographing the pallet with a digital camera, and manually transferring that information to a WMS or TMS system. The automated package dimensioners can do all of this in a matter of seconds, making them worthwhile.

In light of this, we’ll go through some of the key considerations to keep in mind before purchasing the right automated package dimensioner for your vertical.

Range Of Measurement

Dimensioning firms list their units’ measuring length, width, and height capacities. In addition, package dimensioners are available today that can range in various dimensioning, and some organizations customize the dimensioners based on their dimensioning requirements.

Understandably, units capable of dimensioning the most oversized freight tend to be more expensive, which is why it’s wise to figure out which dimensioner is going to be able to accommodate most, if not all, of the freight sizes of your ship. We recommend looking back at the freight you’ve sent in the past four to eight months to do so. You will then build a size profile that accounts for at least 90% of the freight you send ordinarily. To get the best out of your investment, the package dimensioner you choose should be capable of measuring 90 % to 100 % of the freight you send.

Measuring Accuracy

The dimensioning technology used in warehouses and distribution centers significantly impacts the measuring precision of dimensioners. The majority of package dimensioners utilize laser-based or 3D infrared technology. The laser-based package dimensioners were more accurate than infrared; however, infrared dimensioners have narrowed the accuracy gap in recent years. Before choosing the automated package dimensioner to your vertical, ensure the equipment has an NTEP- certified scale.

Measuring Speed

Measuring speed is when the package dimensioner weighs a freight after the dimensioner has been activated. For example, most fully automated package dimensioners can scan a pallet in 3 to 6 seconds, far better than the 25 seconds it takes to measure a pallet manually.

Documentation of freight

Any package dimensioners can take a picture of your freight in addition to weighing and scanning packages to record their state before shipment. This documentation is beneficial in several aspects. The image should be submitted to a transporter, for example, to assist them in determining the right place to stow your freight on a trailer to optimize capacity and prevent damage to your package during transit. If the freight is damaged on the way to its final destination, the captured photo(s) will be used as evidence of a loss allegation, increasing the chances of compensation.

Integration Of Equipment And Process

Assume you want to capture the weight of the package along with the measurements. In that case, you can attach your package dimensioner to a floor or forklift scale. Perhaps you’d like to enable your package dimensioner by scanning a barcode associated with each pallet. Of course, you’ll need to include a barcode scanner for this. Some dimensioners can also be mounted above pallet wrappers, allowing you to wrap and weigh your freight in the same process.

Until you buy, be sure that the automated package dimensioner you’re considering can be adapted to your service and can make your life smoother.

Scalability & Cost

In the decision-making process, the price can still be a significant consideration. Although many top pallet dimensioning manufacturers sell package dimensioners with comparable capabilities, you might be stunned to discover how much they cost. For example, Automated package dimensioners that use laser-based dimensioning technology are generally much more costly than infrared dimensioning technologies. In addition, consider the scalability of your dimensioning process in the future.

Integration Of Software

You can synchronize your package dimensioner with a WMS, TMS, or ERP device to get the best out of it and aid in reducing data entry errors and making greater use of the dimensional data obtained. In other cases, most automated package dimensioning systems can function as stand-alone solutions, with a GUI that allows you to enable the dimensioner and display the recorded measurements in real-time.

Accreditation

Various certifying companies exist in multiple countries. The regulatory bodies assess pallet dimensioners based on precision, maximum and minimum measurement size, and reasonable operating temperature. Before purchasing an automated package dimensioner to your vertical, check for the qualification marks to see if purchasing the dimensioner you’re thinking of is approved.

Conclusion

The explosion of SKUs has resulted from the rise of eCommerce, and there is an ever-increasing need to amuse consumers by providing super-fast fulfillment. However, choosing the right package dimensioner for your warehouse can be difficult nowadays because many considerations must take it into account, like pallet size, weight, capability, certification, measuring speed and accuracy, and the storage and retrieval system used to handle pallets in the warehouse more manageable and efficient.