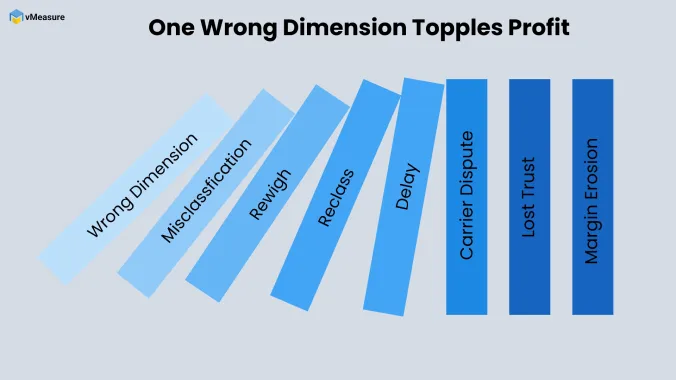

With the new NMFC 13-tier density scale going into effect on July 19, 2025, even small missteps in weight or dimensions can trigger immediate penalties. The margin for error is shrinking, and carriers are no longer overlooking discrepancies.

What triggers freight reclassification under NMFC 2025?

- Freight Reweigh:

Carriers reweigh your shipment if the declared weight doesn’t match what arrives at their facility. Even a minor mismatch can lead to extra charges on the invoice. - Freight Reclassification:

Based on revised weight and dimensions, the shipment may be assigned a new NMFC class, which affects cost, handling, and insurance. - Why It Matters:

The NMFC now calculates class strictly by density. A minor change in volume or packaging can shift your shipment to a more expensive class, even if the item remains the same.

What are the Risks of Misclassifying Freight in 2025?

- Penalties and chargebacks

- Delays in delivery

- Audit triggers from carriers

- Erosion of trust with shipping partners

How can Shippers Avoid NMFC Reclassification Penalties in 2025?

1. Use Packaging That Matches the Freight

2. Measure and Weigh Accurately

3. Understand Freight Density

4. Learn the 13-Tier NMFC Chart

5. Stay Updated on NMFC Changes

6. Watch for Special-Case Items

7. Train Your Teams Regularly

Why is Measurement Accuracy Critical Under the NMFC 13-tier Rule?

Why are Shippers Using Automation to Prevent Reclassification?

Automated pallet dimensioning systems capture exact parcel dimensions and weight within seconds using computer vision. They integrate with your WMS or TMS to update the BOL in real time and eliminate last-minute changes at the dock.

- Faster measurement and fewer delays

- Reduced risk of reclassification

- Seamless audit trails for every shipment

- Standardized data across all facilities

Whether you’re shipping small boxes or heavy pallets, these systems help ensure NMFC compliance with every order and build trust with carriers.

How vMeasure Replaces Guesswork with Verified Freight Data?

Solutions like vMeasure help standardize how weight and dimensions are captured across static stations, conveyor lines, or even mobile environments.

- Ensures dimensional accuracy without manual inputs

- Integrates with WMS/TMS systems to sync directly into your BOL

- Works for both palletized freight and parcel shipments

- Supports lean teams as well as multi-warehouse setups

At a time when every shipment is under scrutiny, the right tools don’t just reduce risk. They unlock operational confidence.