How do density calculations drive your freight costs?

A pallet measuring 35 pounds per cubic foot (PCF) lands in one freight class, while the same pallet calculated at 34 PCF drops into a cheaper bracket, potentially saving $50-75 per shipment under the NMFC 2025 13-tier density scale.

Why do manual measurements create such costly density errors?

Approximation Errors

Inconsistent Measurements Between Shifts

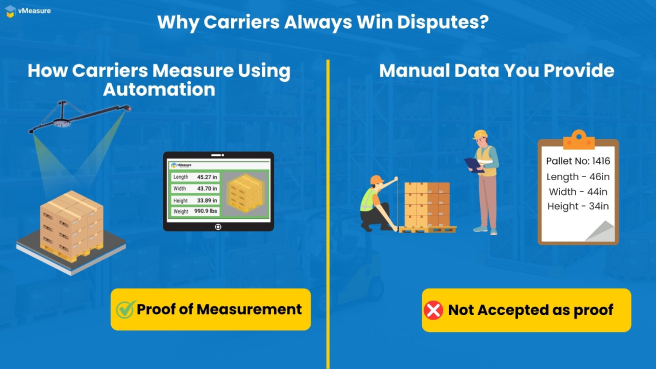

Weak Proof of Measurement

What makes automated pallet dimensioning the solution to cost control?

Automated pallet dimensioning eliminates human error while creating carrier-acceptable documentation. Modern pallet dimensioning systems like vMeasure Pallet Dimensioner use computer vision to achieve ±0.2-inch accuracy. It matches carrier verification standards and prevents audit discrepancies, making NMFC 2025 Compliance far simpler to maintain across all shipments.

What dimensioning technology options work for different operations?

Pallet Dimensioners for high-volume operations

vMeasure Pallet Dimensioners fit right into your existing process and can handle over 300 pallets per hour without slowing things down. Most warehouses recover their investment within 6 to 8 months through a mix of labor savings and fewer freight penalties.

- Easy deployment across sites within 1-2 weeks

- Process irregular or palletized freight in seconds without manual handling delays

- Push verified data straight to your WMS or TMS to eliminate re-entry errors

- Maintain a complete, traceable record to defend against reclassification disputes

Mobile Dimensioners for small-volume operations

vMeasure’s iOS-based dimensioning app provides consistency across parcels or pallets without infrastructure investment. Perfect for operations shipping 50-200 pallets daily.

Key Benefits:

- Install in minutes on your iPhones to start dimensioning

- Create timestamped, audit-ready logs with images tied to each scan

- Push measurements to your WMS or TMS directly through the cloud.

How should you implement dimensioning technology for maximum ROI?

Step 1: Find the Issue

Step 2: Add It to Your Workflow

Install the automated pallet dimensioning system where it fits naturally. For example, right after packing, but before final paperwork. Set up auto-classification and connect it to your existing TMS or WMS, so data flows without extra work. Or opt for a device like the vMeasure pallet dimensioner that automatically pushes the data to your WMS or TMS.

Step 3: Fine-Tune and Improve

How can you optimize freight costs beyond basic measurement?

Better Packaging

Stronger Carrier Negotiations

Smarter Customer Pricing

What financial impact should you expect from implementation?

- Penalty Elimination: $75-150 per avoided reclassification

- Labor Reduction: 2-8 hours daily of measurement time eliminated

- Audit Defense: 90%+ reduction in successful carrier challenges

Operational Efficiency Gains

What are your next steps toward implementation success?

NMFC’s 13-tier density rules have changed LTL shipping. It requires accurate measurement for every shipment, and automated pallet dimensioning systems help you provide it.