How did a fulfillment center use vMeasure SKU image capture feature and eliminate chargebacks?

Industry

Product

Process

Use case

Integration

Case Study Summary

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

The customers were unhappy with the billing as they felt the rates were too expensive and inaccurate. This decreased the company’s goodwill.

The company was getting damage claims frequently and they could not identify the source as they had inadequate documentation because of manual dimensioning.

The company was seeing a high rate of returns as the parcels got damaged.

There were delays in allocating storage space for incoming SKUs as the warehouse associates were predominately using manual dimensioning processes.

SKUs went to undesirable places where it was prone to damage because of the misguided and underinformed put-away process.

Many trucks had to wait for unloading as most of the inbound process was manual and slow. Hence, it was difficult for the trucks to unload at their scheduled time.

As the warehouse starts growing and the order volumes increase, it would be difficult for the current legacy systems to manage such high volumes of data.

They could not find a suitable dimensioning solution that seamlessly integrates with the company’s WMS without demanding drastic makeovers of their existing IT systems.

The company’s technological infrastructure at that point did not support sophisticated integrations.

The customers were unhappy with the billing as they felt the rates were too expensive and inaccurate. This decreased the company’s goodwill.

The company was getting damage claims frequently and they could not identify the source as they had inadequate documentation because of manual dimensioning.

The company was seeing a high rate of returns as the parcels got damaged.

There were delays in allocating storage space for incoming SKUs as the warehouse associates were predominately using manual dimensioning processes.

SKUs went to undesirable places where it was prone to damage because of the misguided and underinformed put-away process.

Many trucks had to wait for unloading as most of the inbound process was manual and slow. Hence, it was difficult for the trucks to unload at their scheduled time.

As the warehouse starts growing and the order volumes increase, it would be difficult for the current legacy systems to manage such high volumes of data.

They could not find a suitable dimensioning solution that seamlessly integrates with the company’s WMS without demanding drastic makeovers of their existing IT systems.

The company’s technological infrastructure at that point did not support sophisticated integrations.

Why did the customer choose vMeasure over other dimensioners?

- Dimensioning Capability

- Software Integration

- Easy Dimensioning Flow

- Physical Characteristics

vMeasure covered all the product/SKU sizes which need to be dimensioned within <1 second.

The accuracy and repeatability metrics aligned with the Operations teams’ expectations.

vMeasure TeamvMeasure Team worked on a custom API that uploaded non-annotated images to the client’s desired server.

The user can configure the units and annotation preferences via the API.

The barcode trigger option helped the warehouse associate to trigger measurement with a scan.

The wireless barcode was seamlessly integrated with the dimensioner without requiring drastic software changes.

vMeasure was small and compact, leaving more space for the warehouse worker to move freely.

The device came with minimal parts and can be installed in 15 – 20 minutes.

vMeasure covered all the product/SKU sizes which need to be dimensioned within <1 second.

The accuracy and repeatability metrics aligned with the Operations teams’ expectations.

vMeasure TeamvMeasure Team worked on a custom API that uploaded non-annotated images to the client’s desired server.

The user can configure the units and annotation preferences via the API.

The barcode trigger option helped the warehouse associate to trigger measurement with a scan.

The wireless barcode was seamlessly integrated with the dimensioner without requiring drastic software changes.

vMeasure was small and compact, leaving more space for the warehouse worker to move freely.

The device came with minimal parts and can be installed in 15 – 20 minutes.

The vMeasure Dimensioning Solution

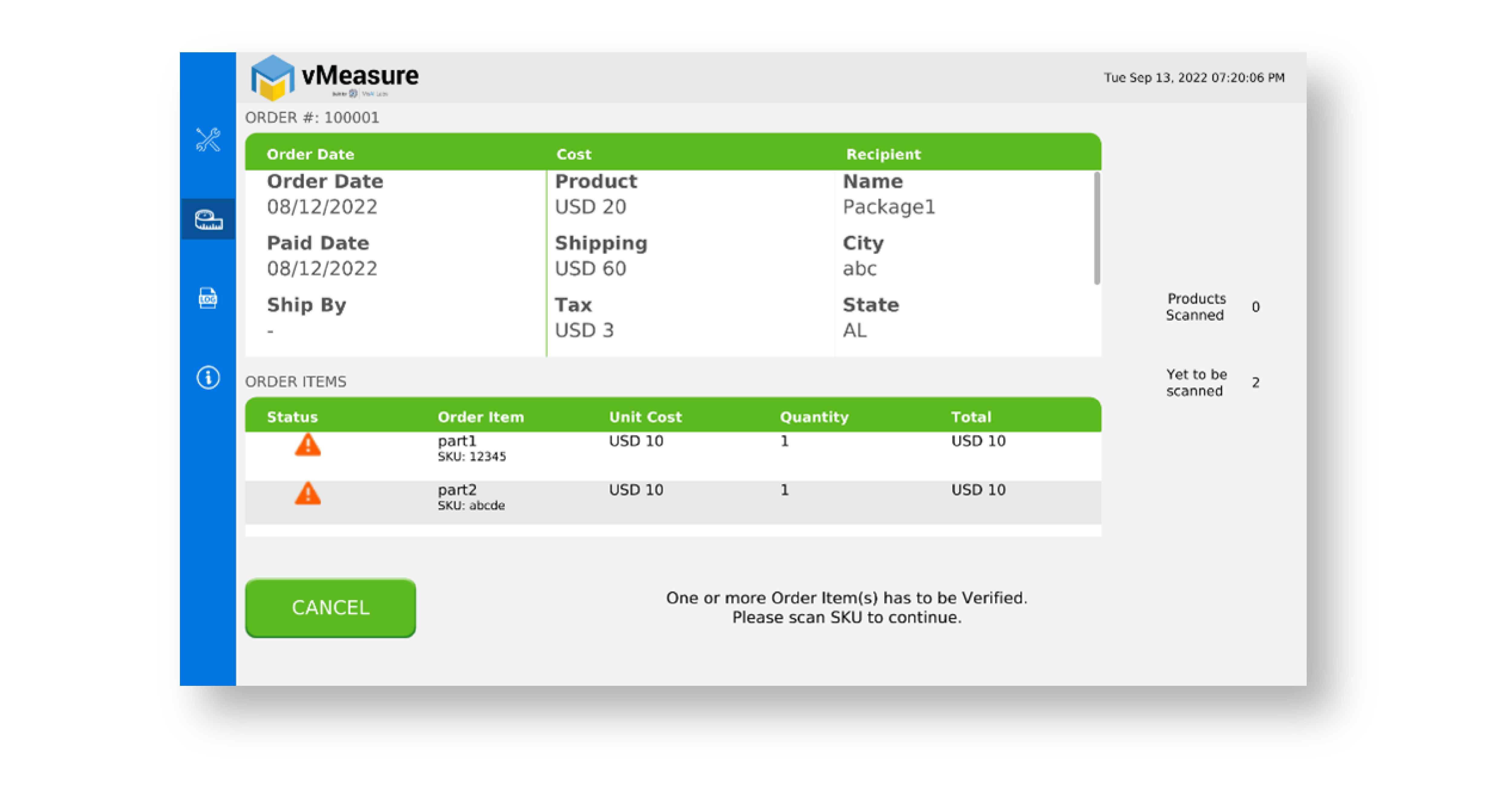

- The order details, along with the SKUs to be packed for the order, are displayed.

- The warehouse associate then scans the individual FNSKU to verify.

- Once all the items are verified using the FNSKU, the warehouse associate then packs the order and places the package on the vMeasure system.

- The warehouse associate scans the confirmation barcode to trigger the measurement on the vMeasure system.

- Once the measurement is triggered, the vMeasure system automatically dimensions the package and updates the corresponding data to Ship-Station

- The vMeasure system returns to the order ID scan screen automatically once the data upload to ShipStation is complete.

How did the client benefit from vMeasure parcel weigh dimensioner?

- Business

- Operational

- Administrative

The company could now charge its customers accurately with the help of the right parcel dimensions.

The SKU image capture feature helped them protect against damage claims and pinpoint parcel damage or pilferage. As a result, the company reduced its returns.

The company was now able to reduce costs including labor costs, material costs, and the costs of potential mistakes.

Automated dimensioner enabled the business to scale further and handle more volumes of parcels.

Warehouse associates allocated less time for reverse logistics as customer returns reduced and SKU health improved because the SKU image capture enabled better quality control.

The speed of the receiving and put away process improved as the warehouse associates took less than 3 seconds for end-to-end dimensioning.

Accurate product-level dimensions went into WMS and as a result, each inbound SKU was allotted a safe storage space.

The SKU image capture feature in the inbound stage complimented picking at the outbound stage and ensured the right orders were picked by referring the image and the product dimensions.

The SKU images served as proof of the shipment’s health and receipt and saved a lot of time that would have otherwise been wasted in disputes.

Accurate measurement data provided a clear record of inbound logistics operations, making auditing and regulatory compliance easier to manage.

Streamlined record-keeping and SKU data management, leading to more efficient information retrieval through vMeasure Forge.

The admin team spent less time collaborating with other departments since they got all the billing information from the vMeasure system.

What makes vMeasure the only vMeasure parcel weigh dimensioner

capable of solving your needs?

- Small SKU Mode

- All Parcel Mode

- White Goods Mode

- Mount Height

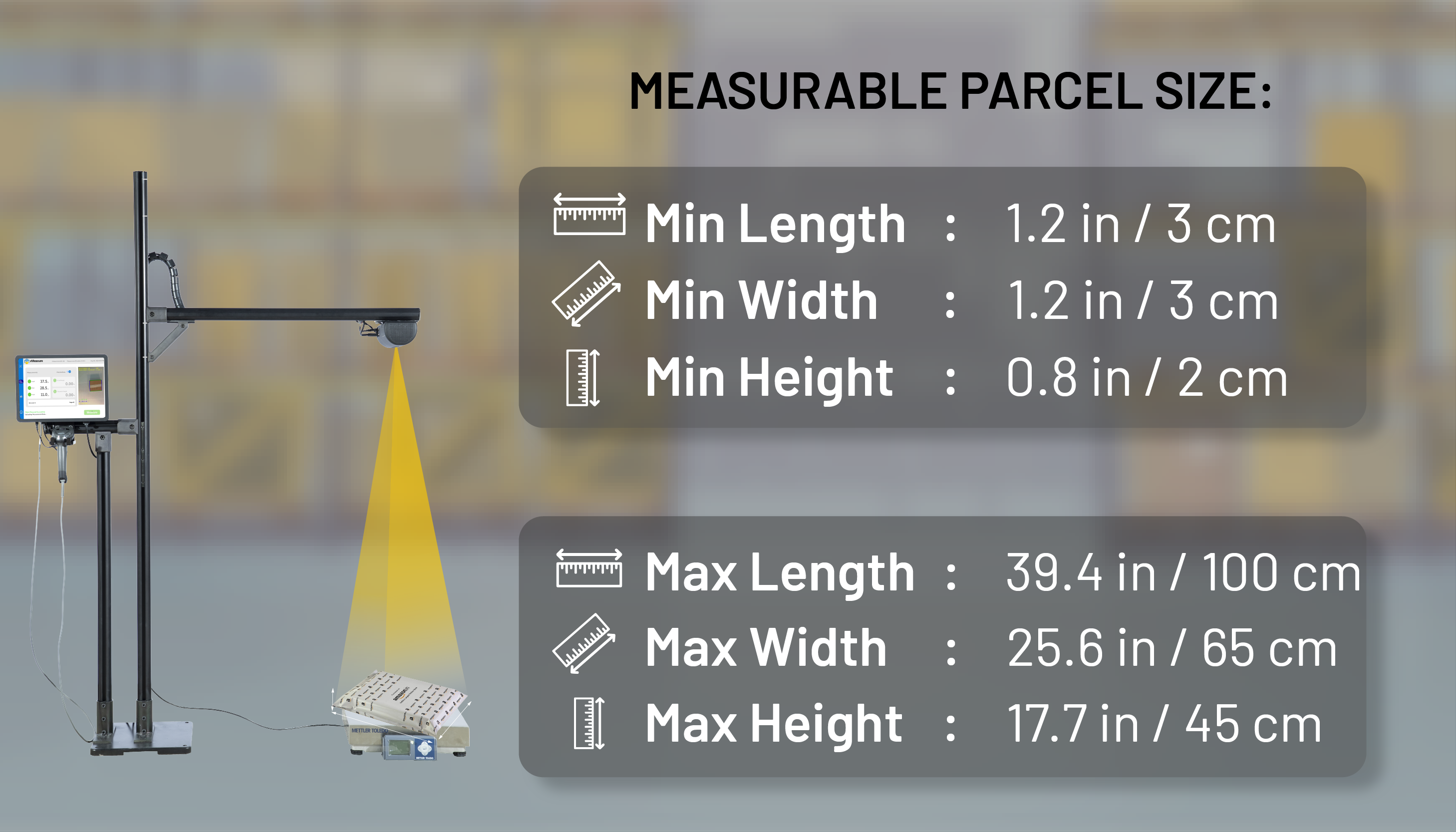

- Min and Max Measurable Size

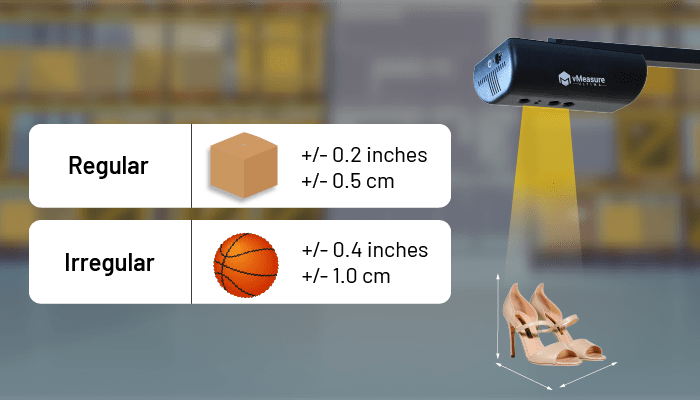

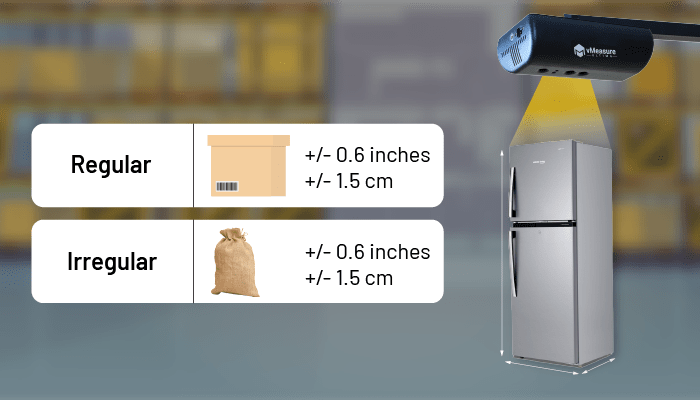

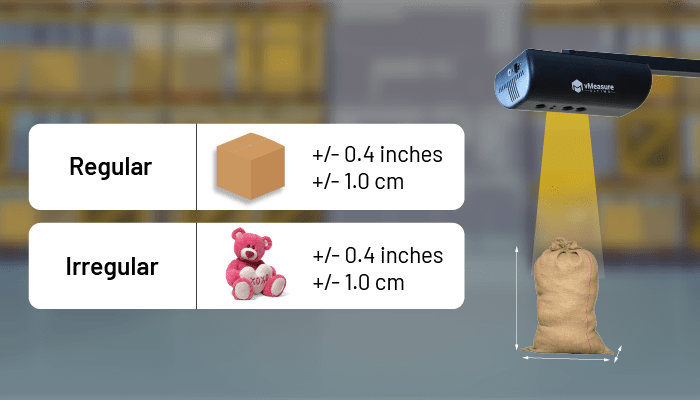

- Measuring Accuracy

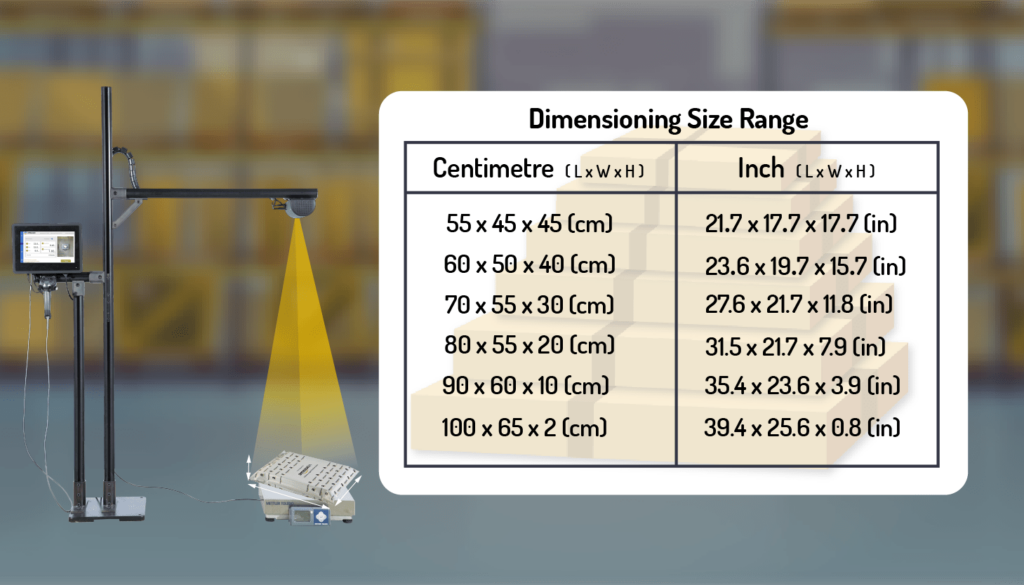

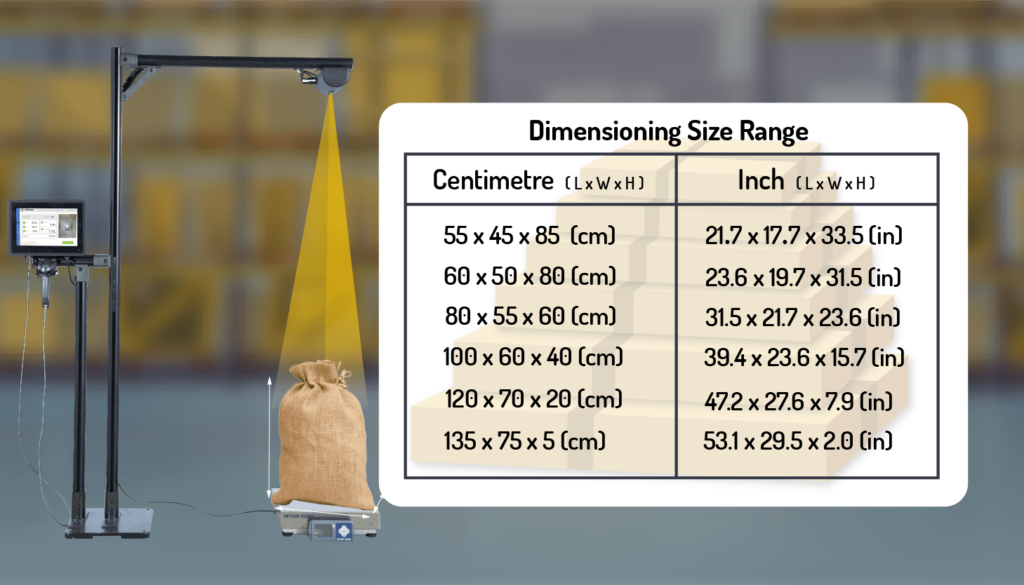

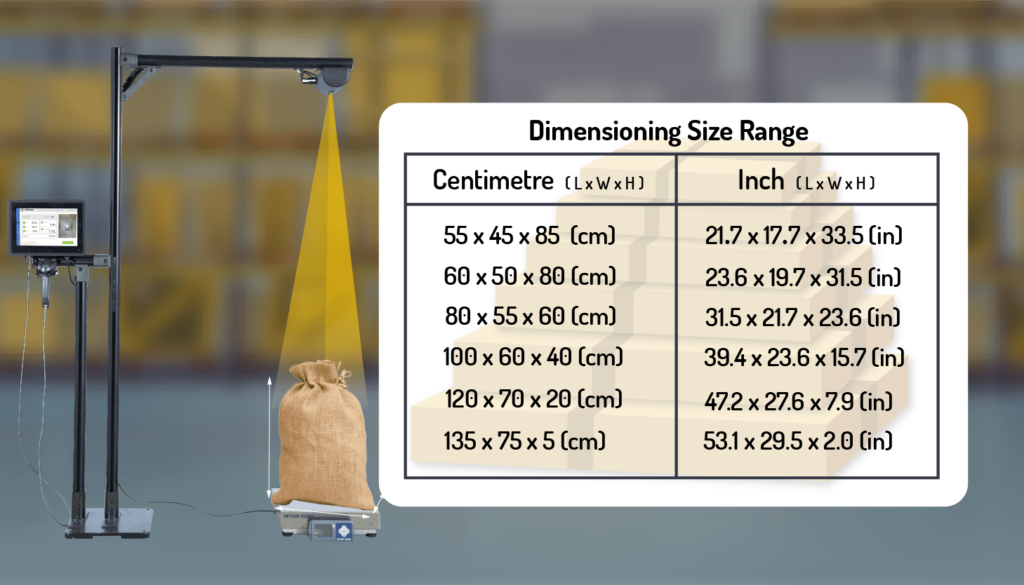

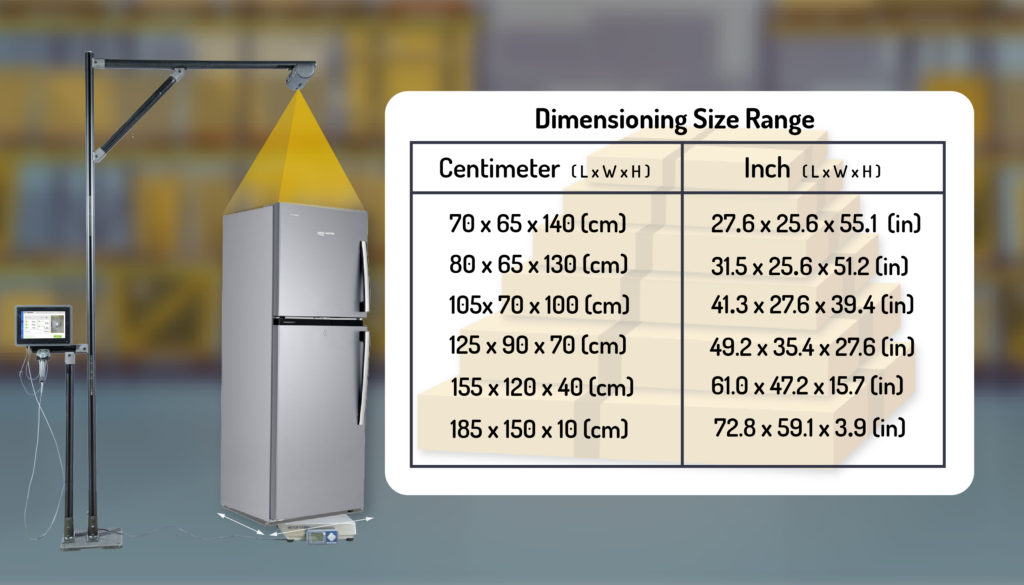

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

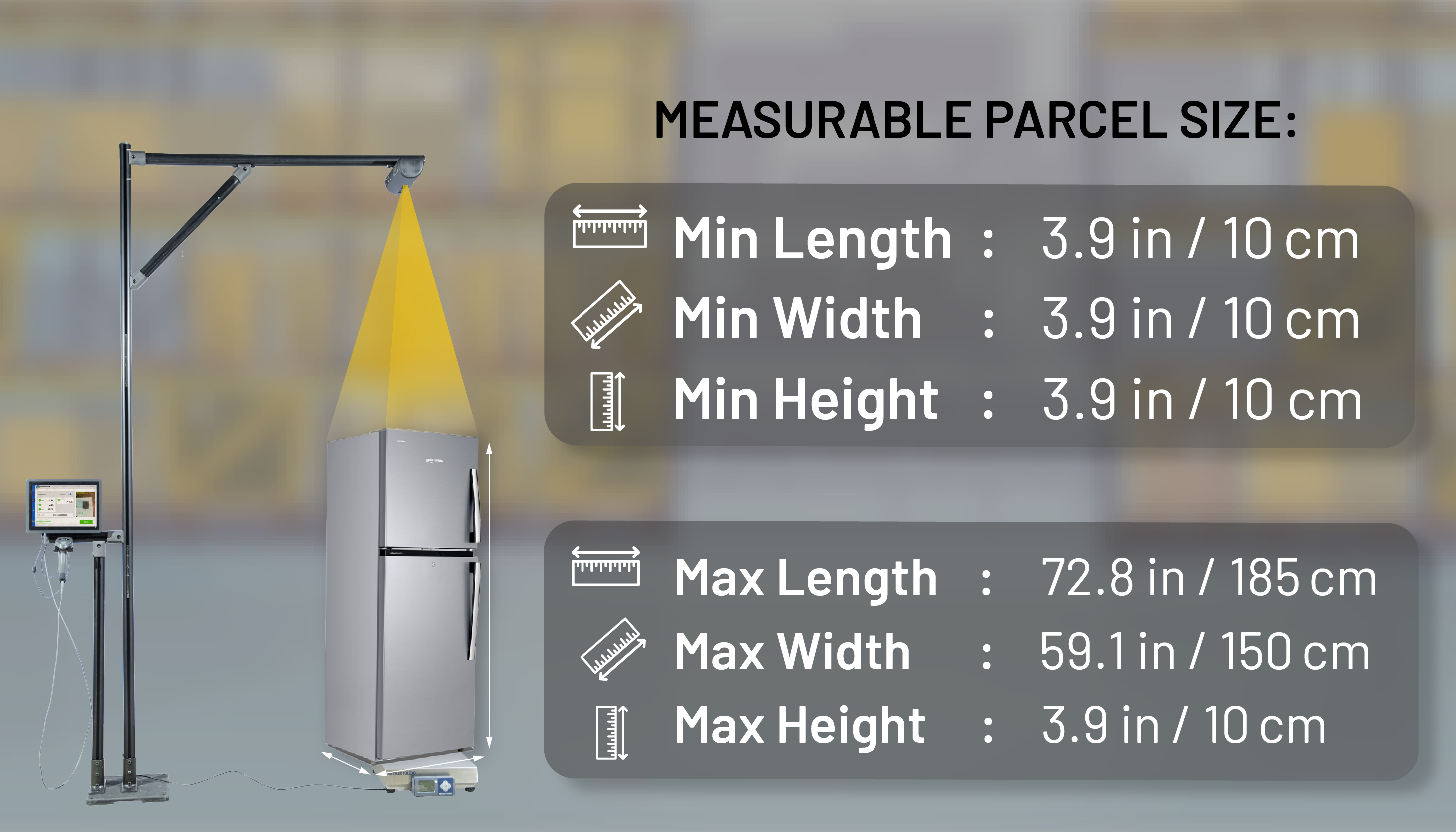

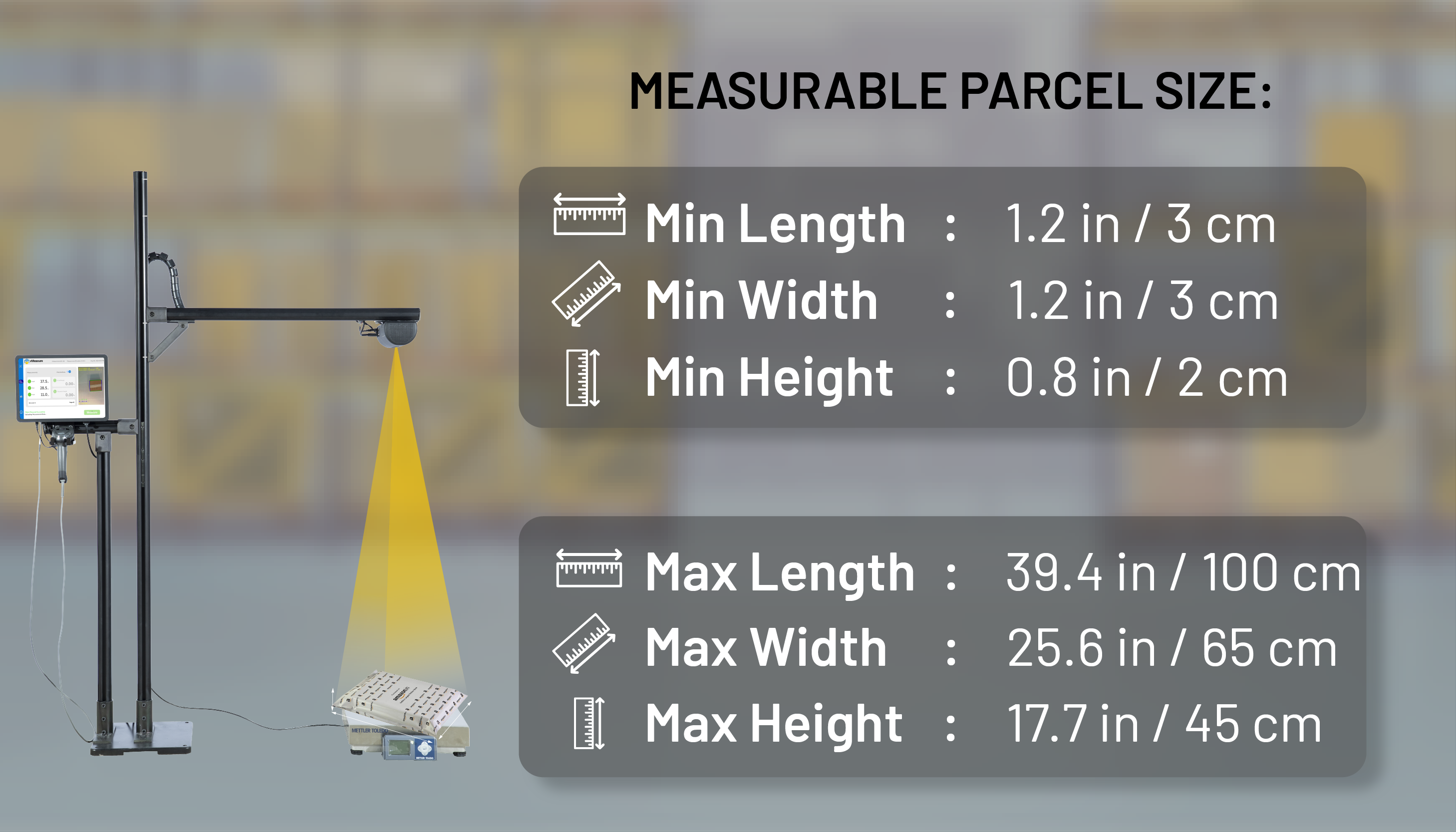

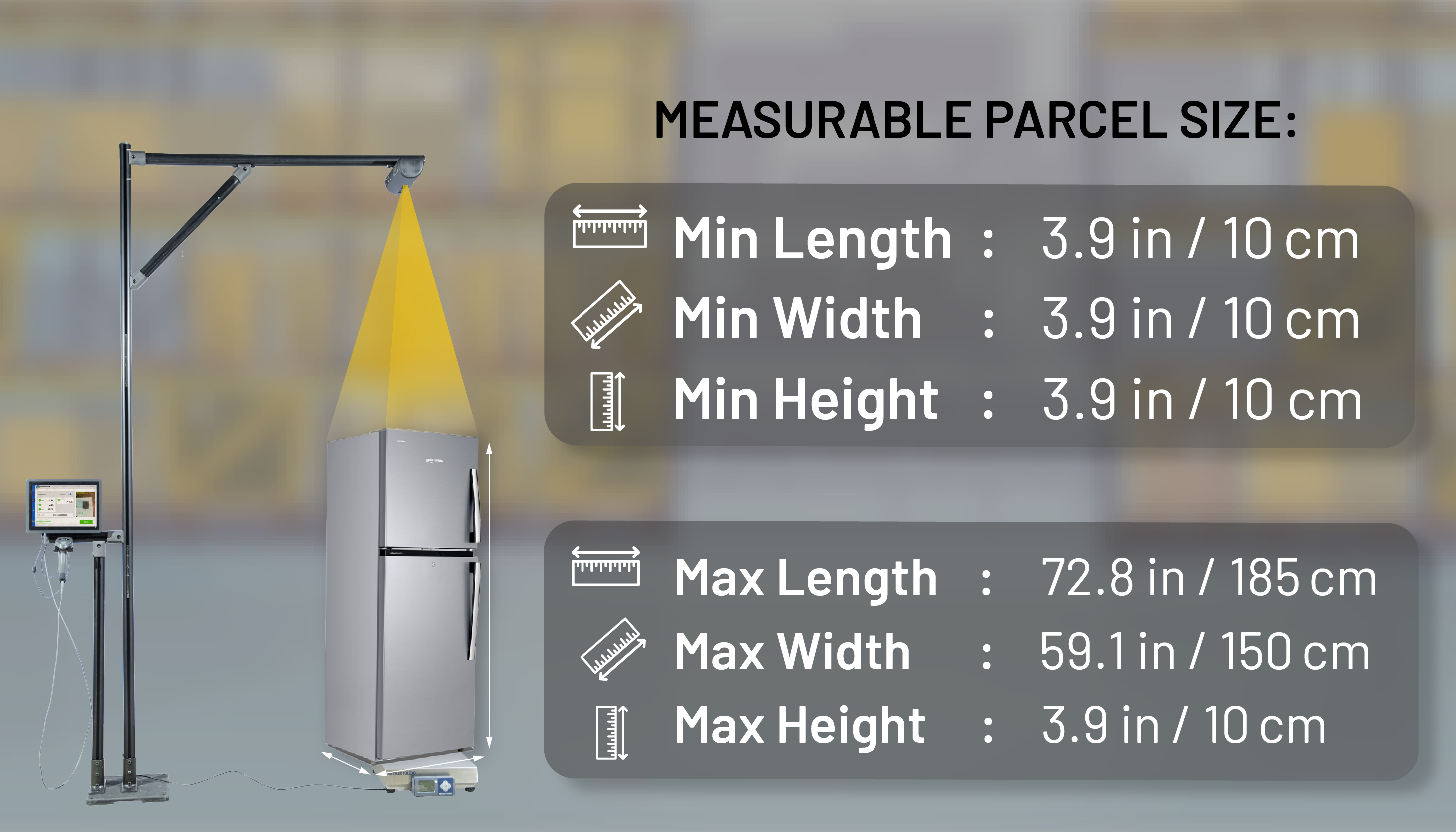

- Min and Max Measurable Size

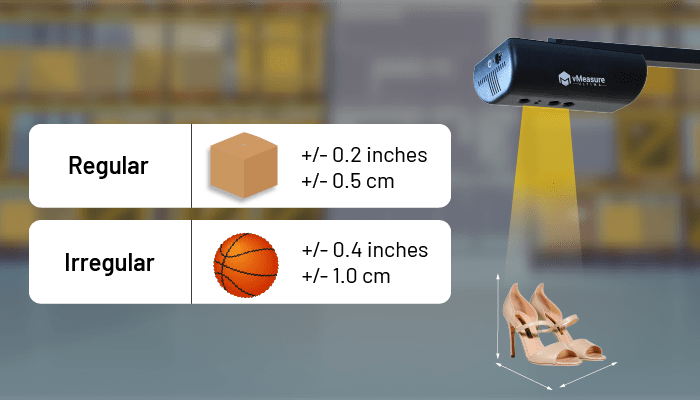

- Measuring Accuracy

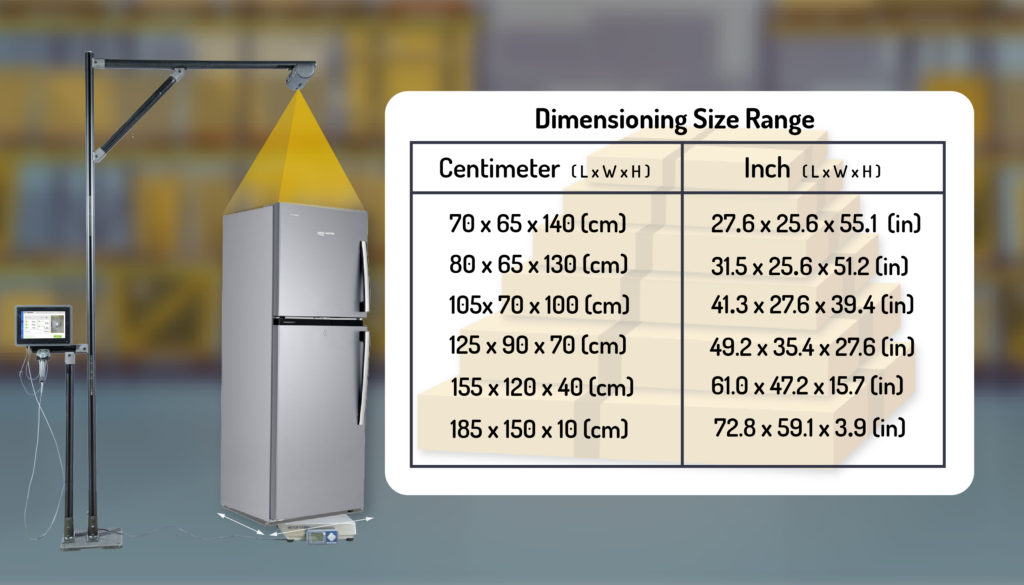

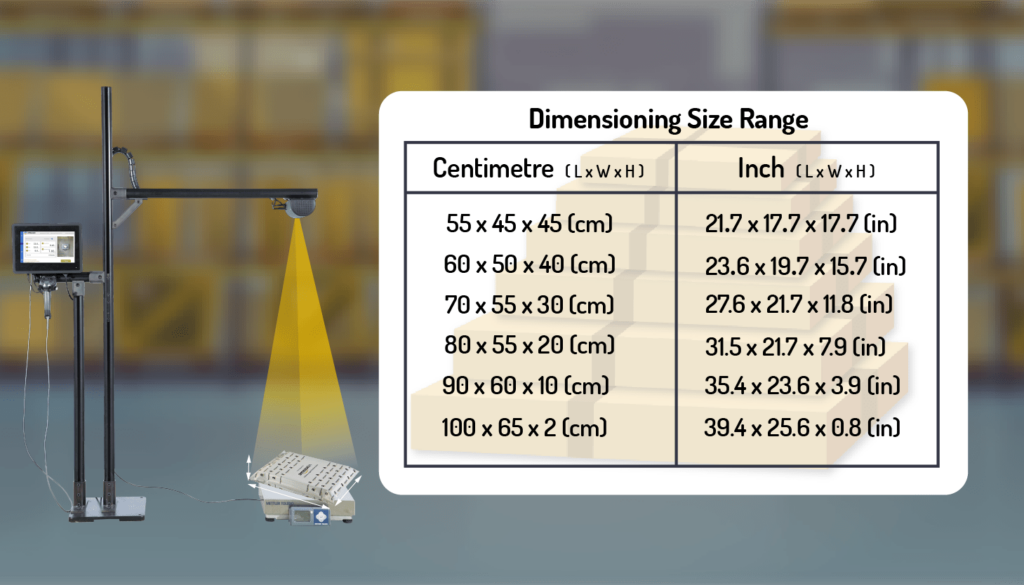

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

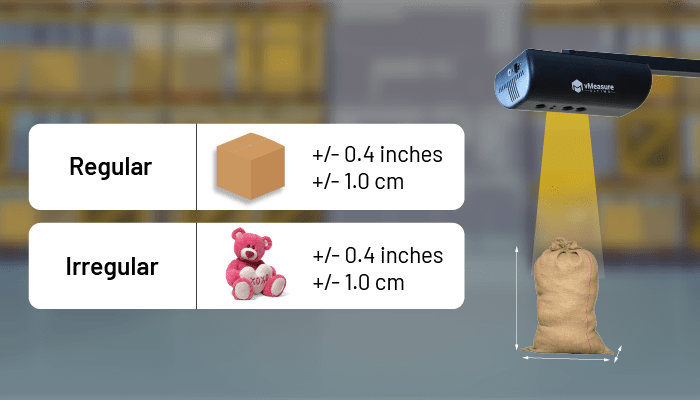

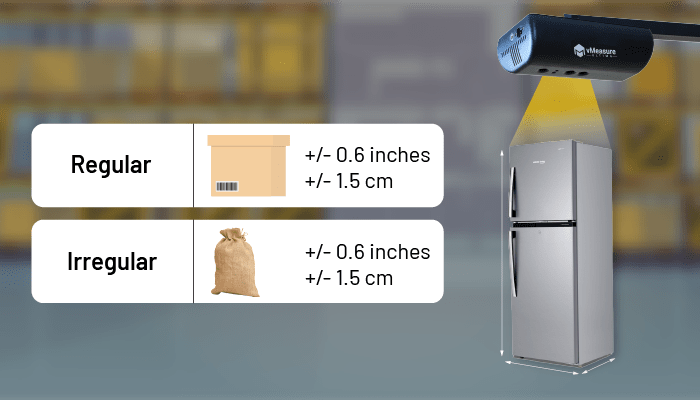

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods