How an OEM wholesale distributor saved on shipping through vMeasure Automated Dimensioner?

Industry

Product

Process

Use case

Integration

Software Integrated

Case Study Summary

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

As the only wholesale distributor of their own products, the client was under heavy pressure to optimize operational costs with shipping

Due to the high volume of orders managed in a limited space, sometimes wrong SKUs are picked for each order and packed, leading to reduced customer satisfaction

Low parcel throughput at the packing station due to manual dimensioning for data input into the system

As the only wholesale distributor of their own products, the client was under heavy pressure to optimize operational costs with shipping

Due to the high volume of orders managed in a limited space, sometimes wrong SKUs are picked for each order and packed, leading to reduced customer satisfaction

Low parcel throughput at the packing station due to manual dimensioning for data input into the system

Why did the customer choose vMeasure dimensioning system to solve

the above logistics problems?

- Dimensioning Capability

- Integration

- On-Screen Customization

- Physical Characteristics

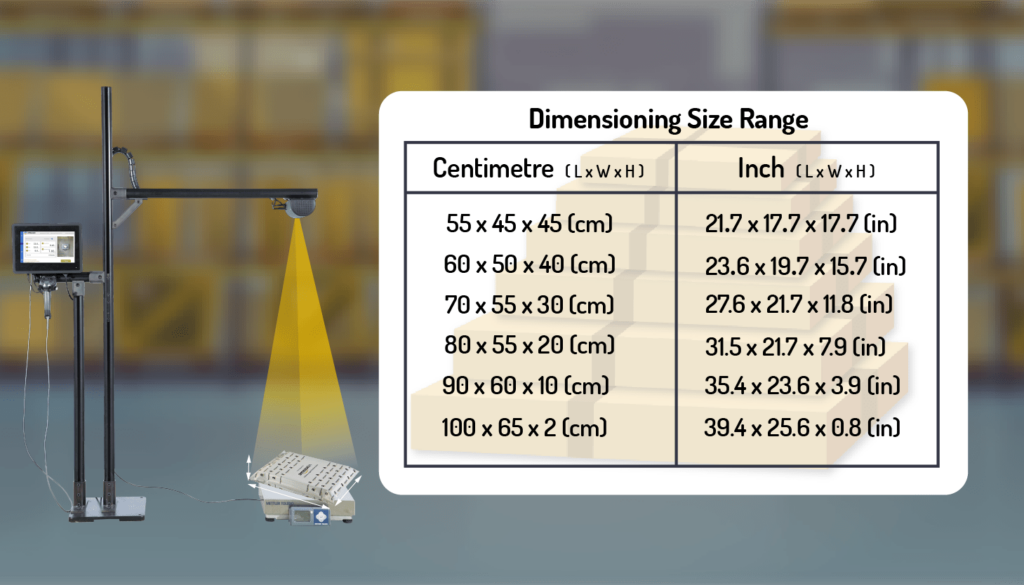

can cover all the product/SKU sizes which need to be dimensioned

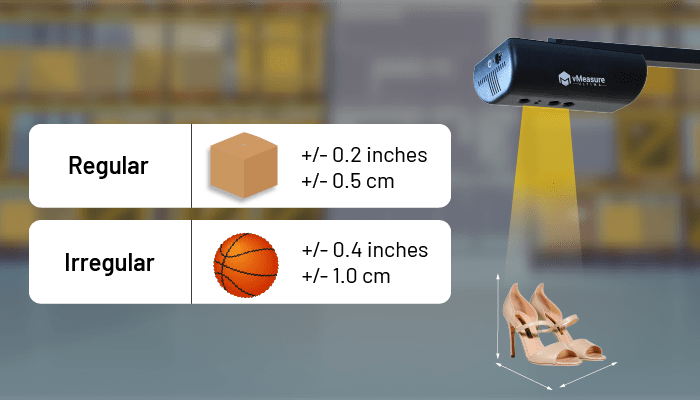

The accuracy and repeatability metrics were in-line with the Operations teams' expectation

vMeasure Dimensioner provided direct native integration to Shipstation through APIs

Easily call all order data from Shipstation and list the SKUs/products per order, enabling order verification in-site at packing stations

Customizable to display the complete list of orders to be packed for the shift along with SKUs orders

Ability to use the integrated barcode scanner along with the vMeasure's deep integration

The vMeasure system is small and compact and comes integrated with a weighing scale and a barcode scanner

The touch screen allows the system to work standalone without needing a separate computer/laptop, thereby saving packing station space

can cover all the product/SKU sizes which need to be dimensioned

The accuracy and repeatability metrics were in-line with the Operations teams' expectation

vMeasure Dimensioner provided direct native integration to Shipstation through APIs

Easily call all order data from Shipstation and list the SKUs/products per order, enabling order verification in-site at packing stations

Customizable to display the complete list of orders to be packed for the shift along with SKUs orders

Ability to use the integrated barcode scanner along with the vMeasure's deep integration

The vMeasure system is small and compact and comes integrated with a weighing scale and a barcode scanner

The touch screen allows the system to work standalone without needing a separate computer/laptop, thereby saving packing station space

The vMeasure Dimensioning Solution

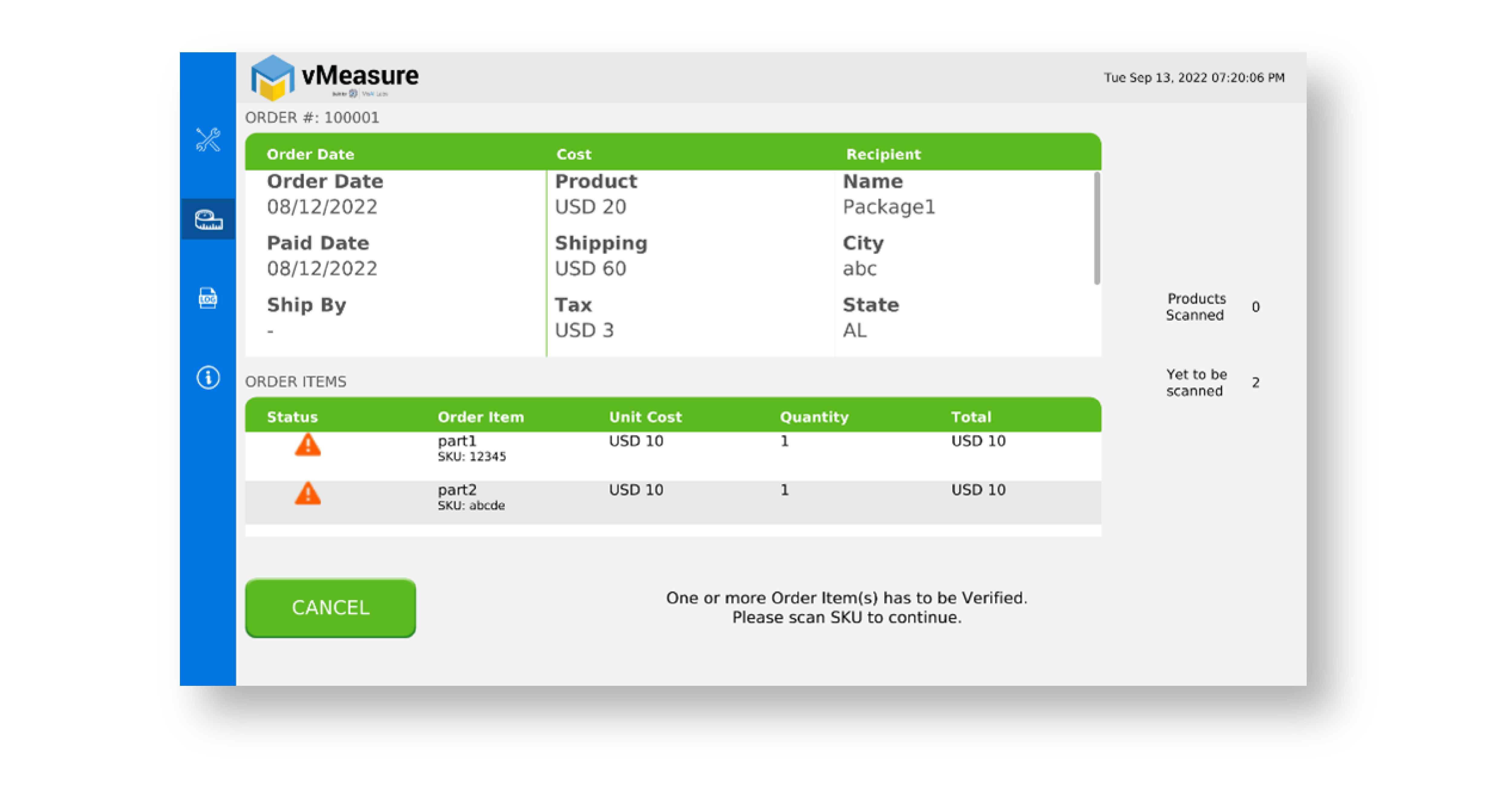

- The order details, along with the SKUs to be packed for the order, are displayed.

- The warehouse associate then scans the individual FNSKU to verify.

- Once all the items are verified using the FNSKU, the warehouse associate then packs the order and places the package on the vMeasure system.

- The warehouse associate scans the confirmation barcode to trigger the measurement on the vMeasure system.

- Once the measurement is triggered, the vMeasure system automatically dimensions the package and updates the corresponding data to Ship-Station

- The vMeasure system returns to the order ID scan screen automatically once the data upload to ShipStation is complete.

Benefits accrued by the client by using vMeasure dimensioning system

- Business

- Operational

- Administrative

Easy Compliance with Dim Pricing by providing accurate dimensions

Reduced carbon emission as the shipping volumes dropped

Increased Parcel throughput by shipping more orders per sq. ft of fulfillment center

Increased customer verification

Faster Packing process by saving up to 30% of their packing time

Reduced steps taken to dimension packages from 6 manual steps to 2

Improve order verification by making sure the right SKU is shipped by mapping dimensions & product to each order accurately

Reduced risk of using inaccurate data for shipping or data management entered manually

Eliminated the anxiety which arises from interacting with 3PLs due to inaccurate chargebacks

provided information clarity to their finance team by getting accurate shipping costs with accurate parcel dimensions

Reduced risk of lack of labor by improving automation at the shipping station

Simplified the process of generating labels from multi-carrier shipping software

What makes vMeasure the only static parcel dimensioner

capable of solving your needs?

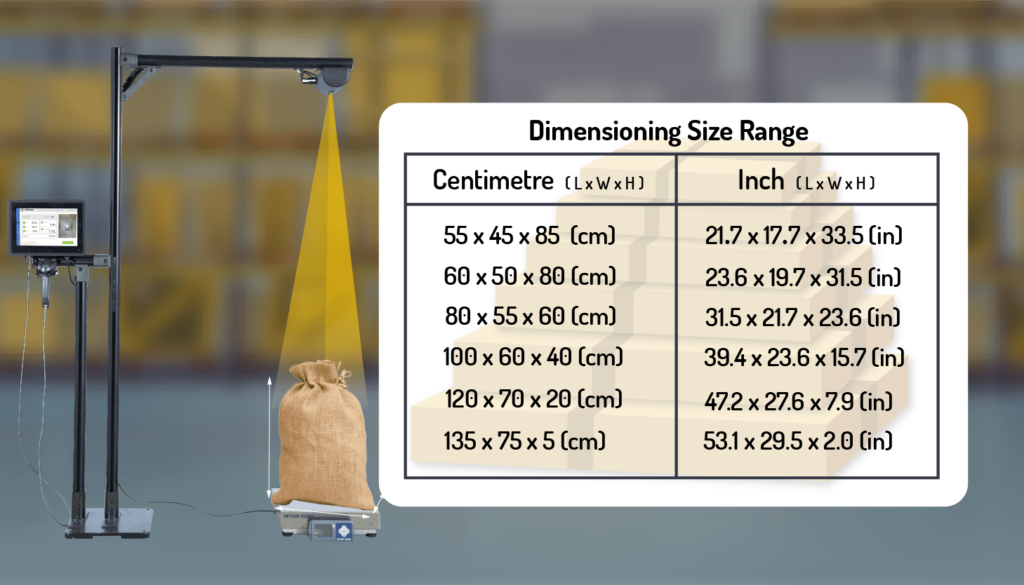

- Small SKU Mode

- All Parcel Mode

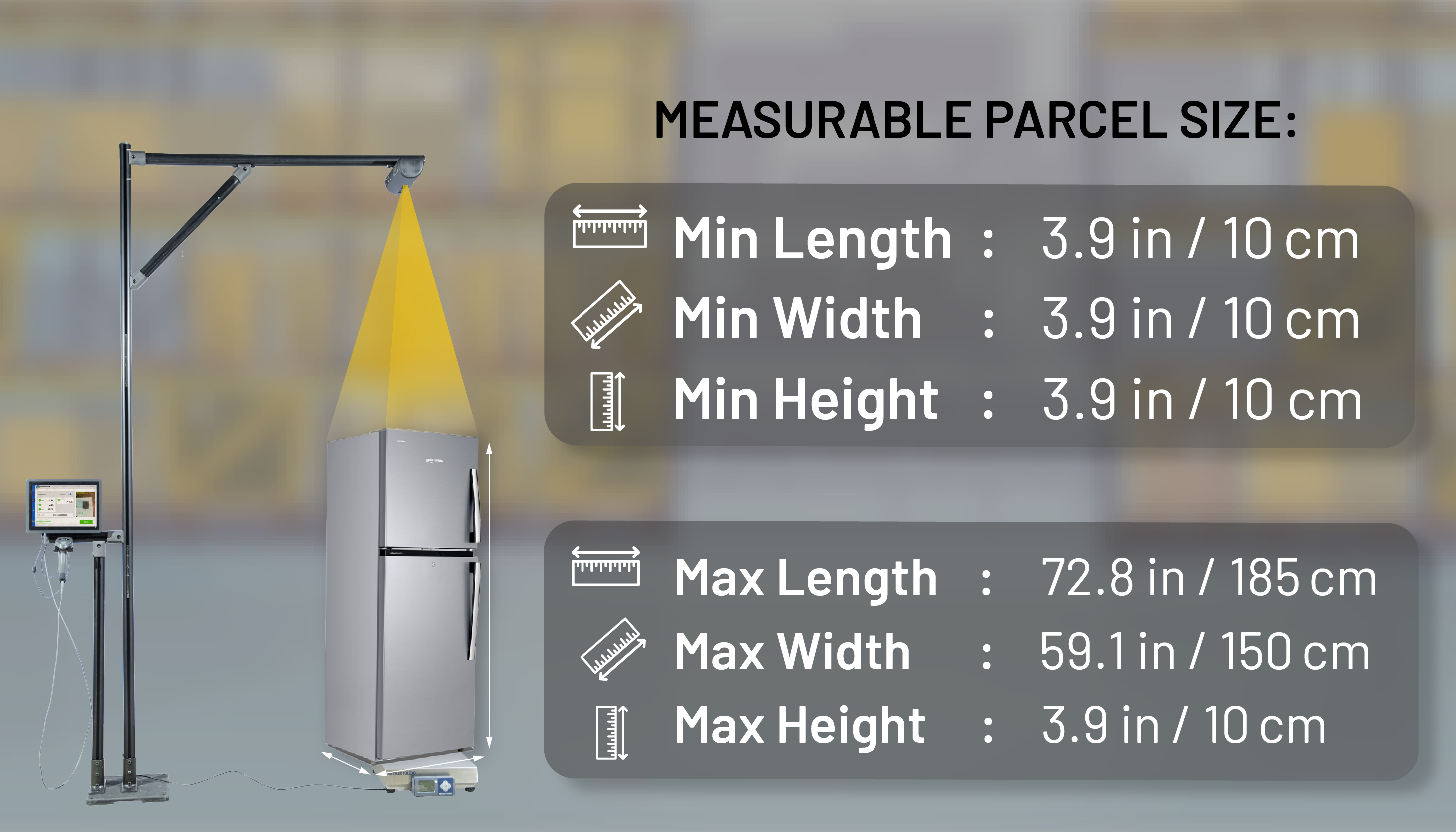

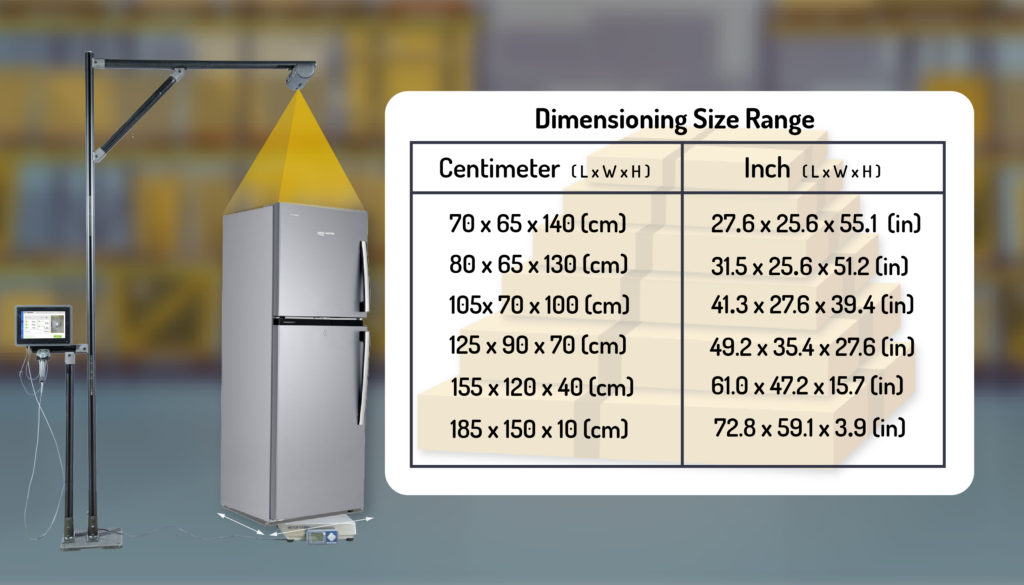

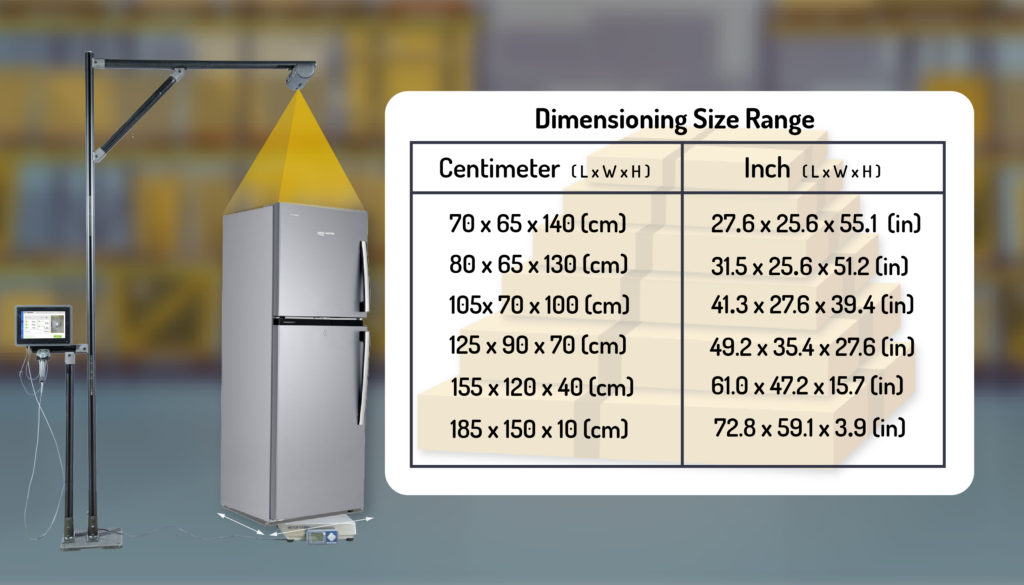

- White Goods Mode

- Mount Height

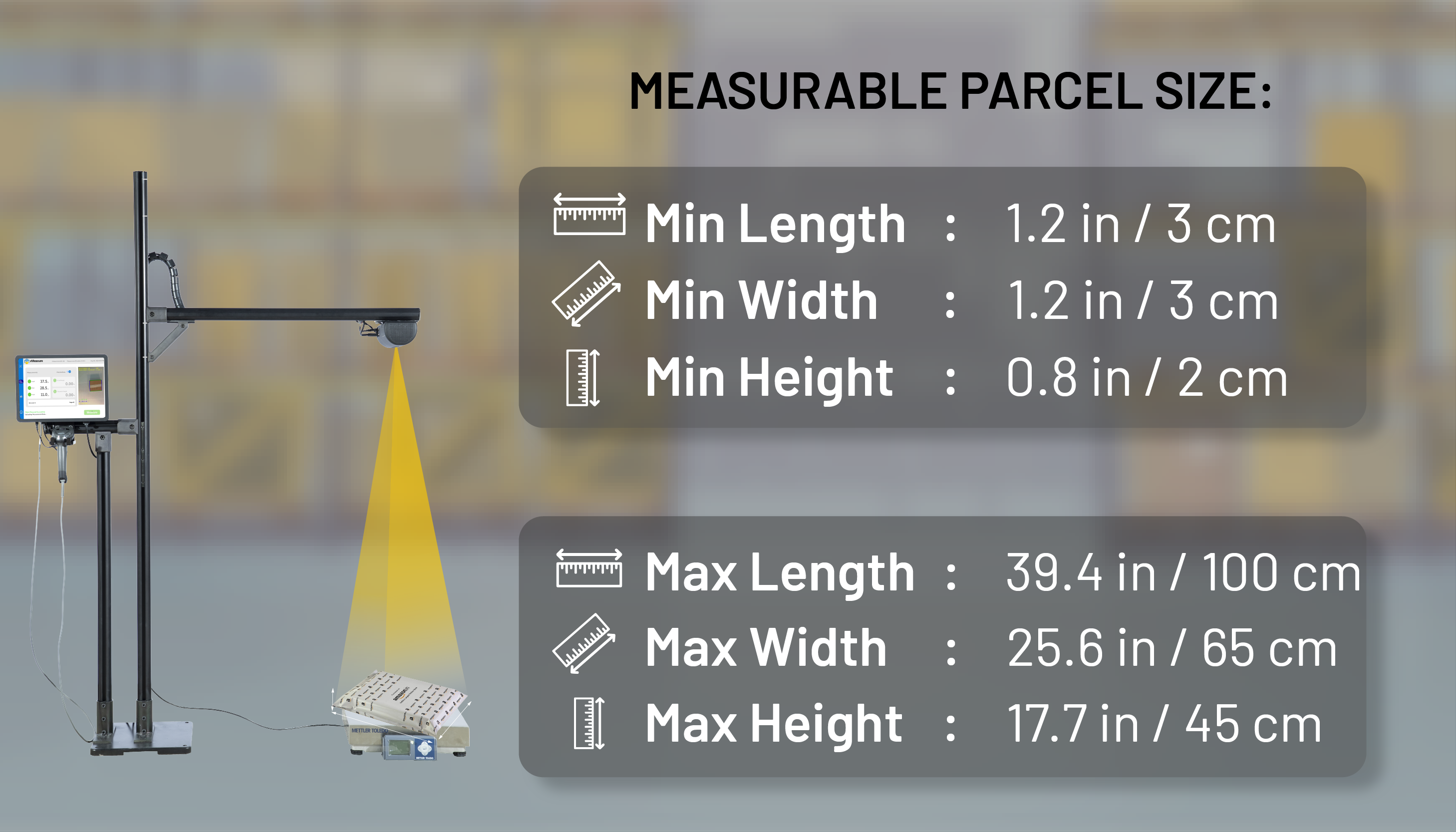

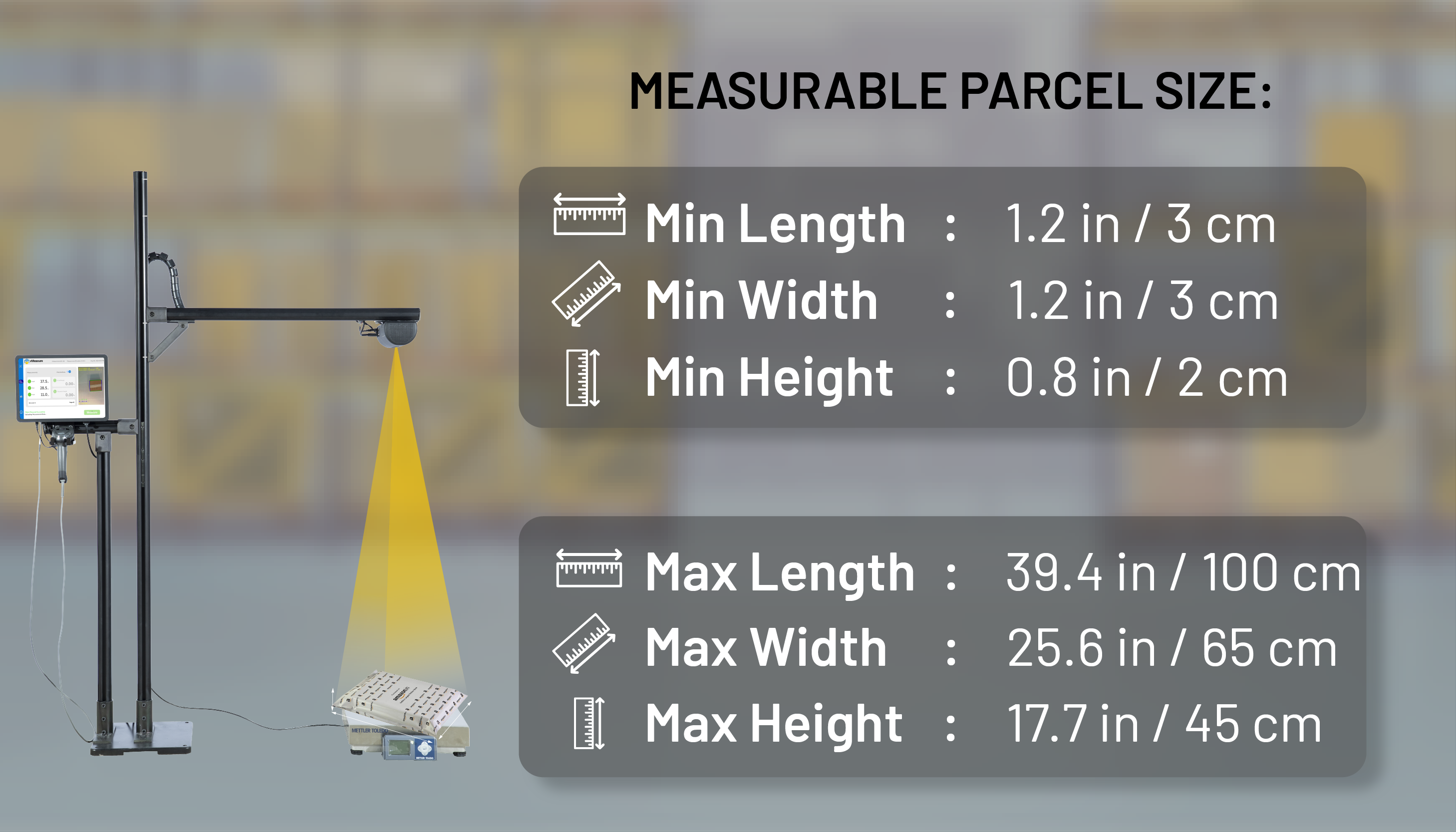

- Min and Max Measurable Size

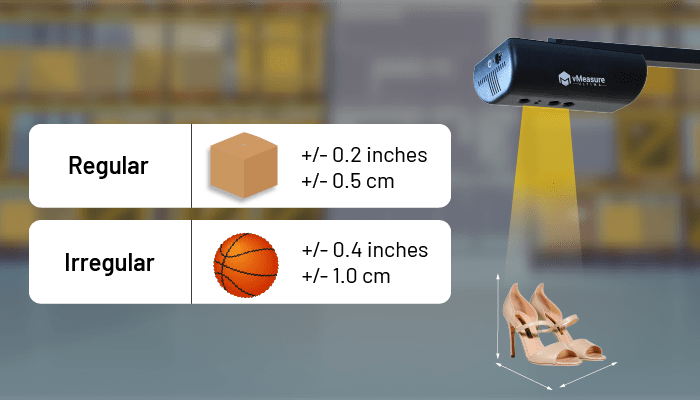

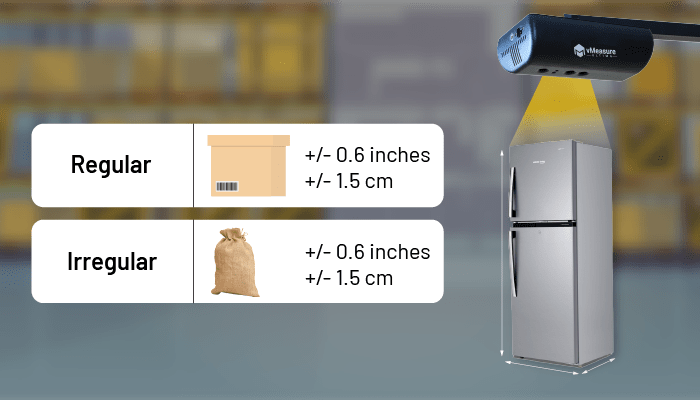

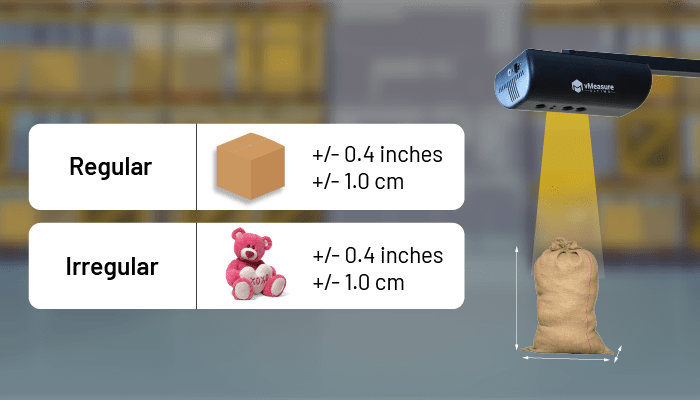

- Measuring Accuracy

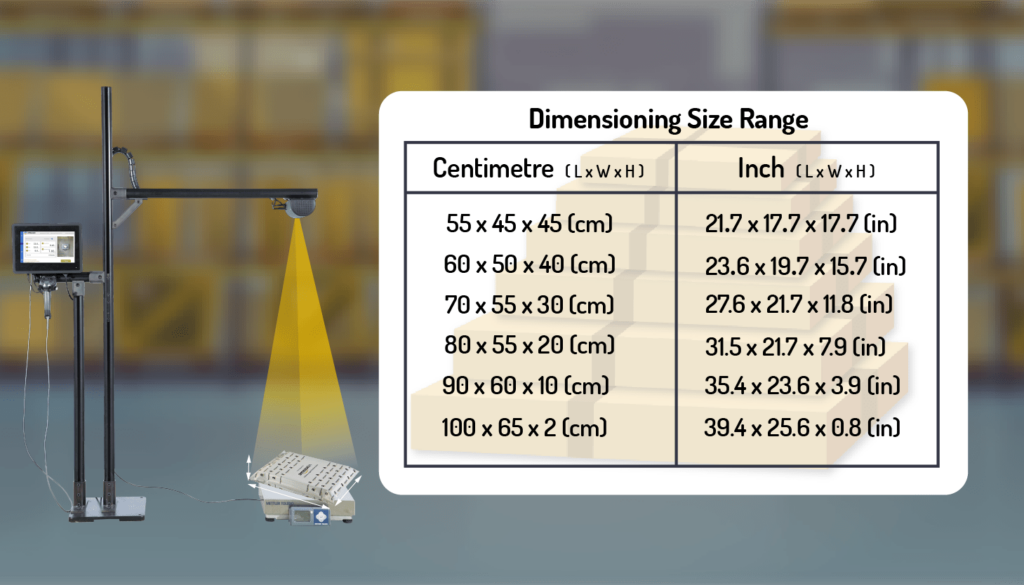

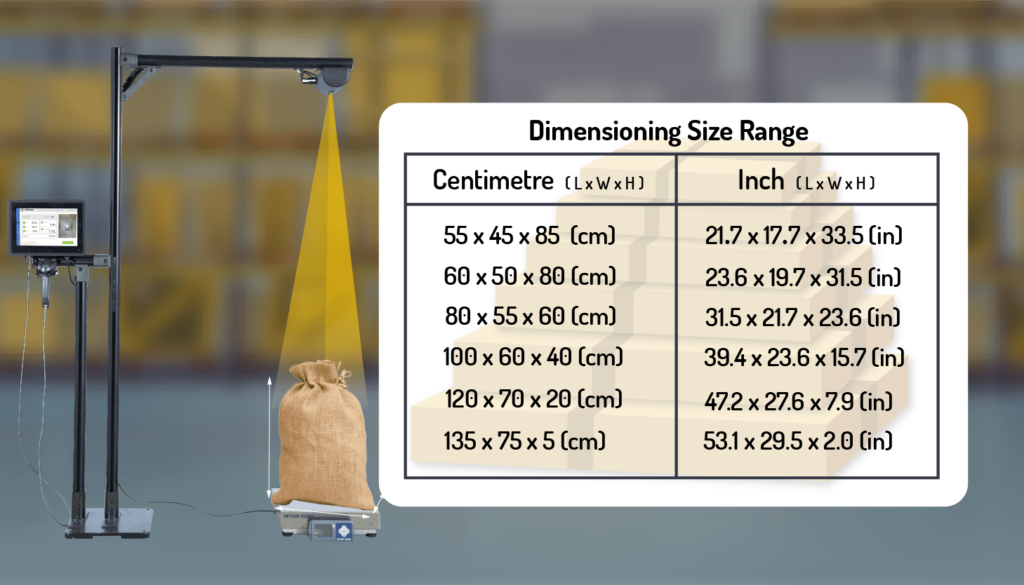

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

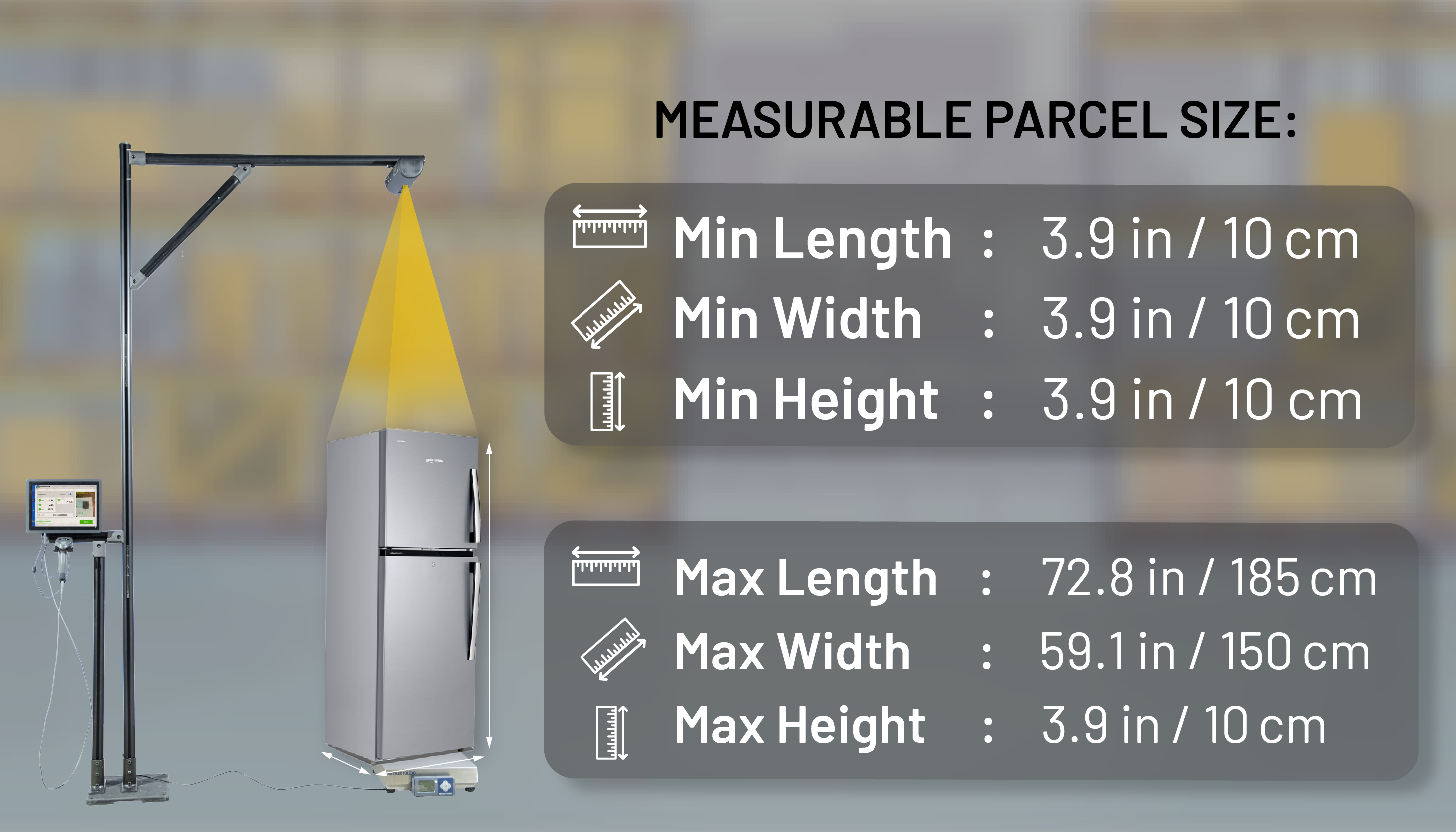

- Min and Max Measurable Size

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

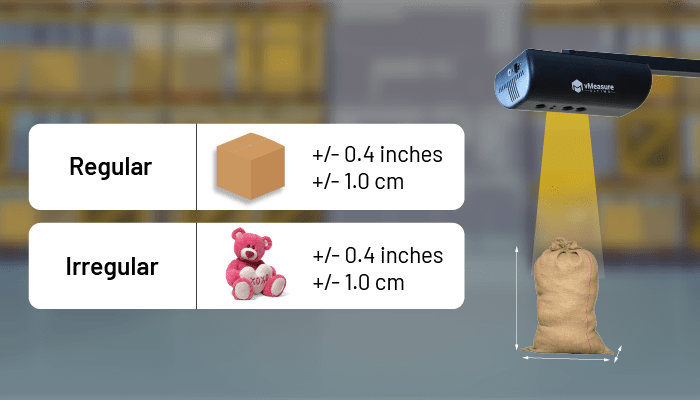

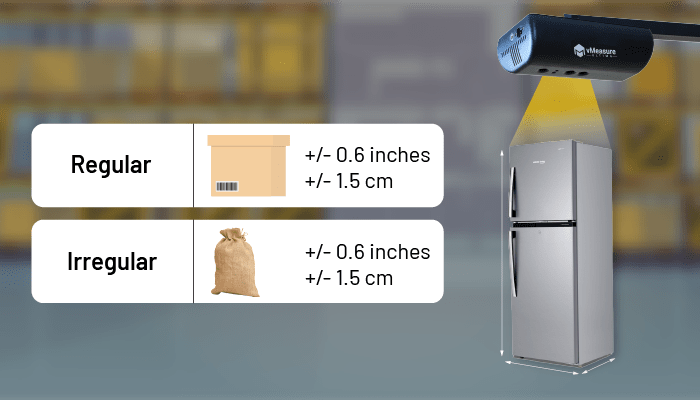

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods