How a Road Freight Distribution firm expedited Truck movement through accurate dimensioning?

Industry

Product

Process

Use case

Integration

Case Study Summary

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

Delays in loading, unloading, and waybill creation made it difficult for the truck to comply with state intracity traffic rules & regulations, leading to missed deliveries.

The company could not identify the touchpoint where the parcels get damaged. This lowered customer satisfaction.

The company saw increased logistics & operational costs due to erroneous data from manual measurements and a lack of optimized warehouse storage.

Low parcel throughput created long lines of parcels at the receiving dock waiting to be processed since the workers manually measured the inbound parcels.

The company did not use the truck capacity since the loads assigned to the truck were not optimized. So, the trucks were either overloaded or underloaded.

Wrong DIMs in the waybill led to lower revenue recovery

The IT team could not allocate resources to make complex WMS and TMS integrations.

Simplicity and data security weighed in on them for selecting an integration solution.

They did not have enough space for an additional desktop setup if the dimensioner was installed.

Delays in loading, unloading, and waybill creation made it difficult for the truck to comply with state intracity traffic rules & regulations, leading to missed deliveries.

The company could not identify the touchpoint where the parcels get damaged. This lowered customer satisfaction.

The company saw increased logistics & operational costs due to erroneous data from manual measurements and a lack of optimized warehouse storage.

Low parcel throughput created long lines of parcels at the receiving dock waiting to be processed since the workers manually measured the inbound parcels.

The company did not use the truck capacity since the loads assigned to the truck were not optimized. So, the trucks were either overloaded or underloaded.

Wrong DIMs in the waybill led to lower revenue recovery

The IT team could not allocate resources to make complex WMS and TMS integrations.

Simplicity and data security weighed in on them for selecting an integration solution.

They did not have enough space for an additional desktop setup if the dimensioner was installed.

Why did the customer choose vMeasure dimensioning machines

over other dimensioners?

- Dimensioning Capability

- Software Integration

- Hardware Customization

- Cost

vMeasure Dimensioner can cover all the product/SKU sizes which need to be dimensioned within <1 second

The accuracy and repeatability metrics with the Operations teams’ expectations

vMeasure Dimensioner was integrated with the client’s WMS and TMS without impacting the existing physical and electronic processes

The integration allowed them to provide the right dimensions to generate shipping invoices and deploy load management strategies using TMS.

The vMeasure system came with an additional camera to provide a better 3-dimensional view of the parcel and was mounted over a mechanical roller for higher throughput

vMeasure and its partner provided a solution where the Volumizer was fitted with an inverter and lithium battery making it completely mobile and usable in various parts of the warehouse

The company felt vMeasure to be more cost-effective than the rest of the dimensioners

The difference was as much as 60% from vMeasure’s next economical option

vMeasure Dimensioner can cover all the product/SKU sizes which need to be dimensioned within <1 second

The accuracy and repeatability metrics with the Operations teams’ expectations

vMeasure Dimensioner was integrated with the client’s WMS and TMS without impacting the existing physical and electronic processes

The integration allowed them to provide the right dimensions to generate shipping invoices and deploy load management strategies using TMS.

The vMeasure system came with an additional camera to provide a better 3-dimensional view of the parcel and was mounted over a mechanical roller for higher throughput

vMeasure and its partner provided a solution where the Volumizer was fitted with an inverter and lithium battery making it completely mobile and usable in various parts of the warehouse

The company felt vMeasure to be more cost-effective than the rest of the dimensioners

The difference was as much as 60% from vMeasure’s next economical option

The vMeasure Dimensioning Solution

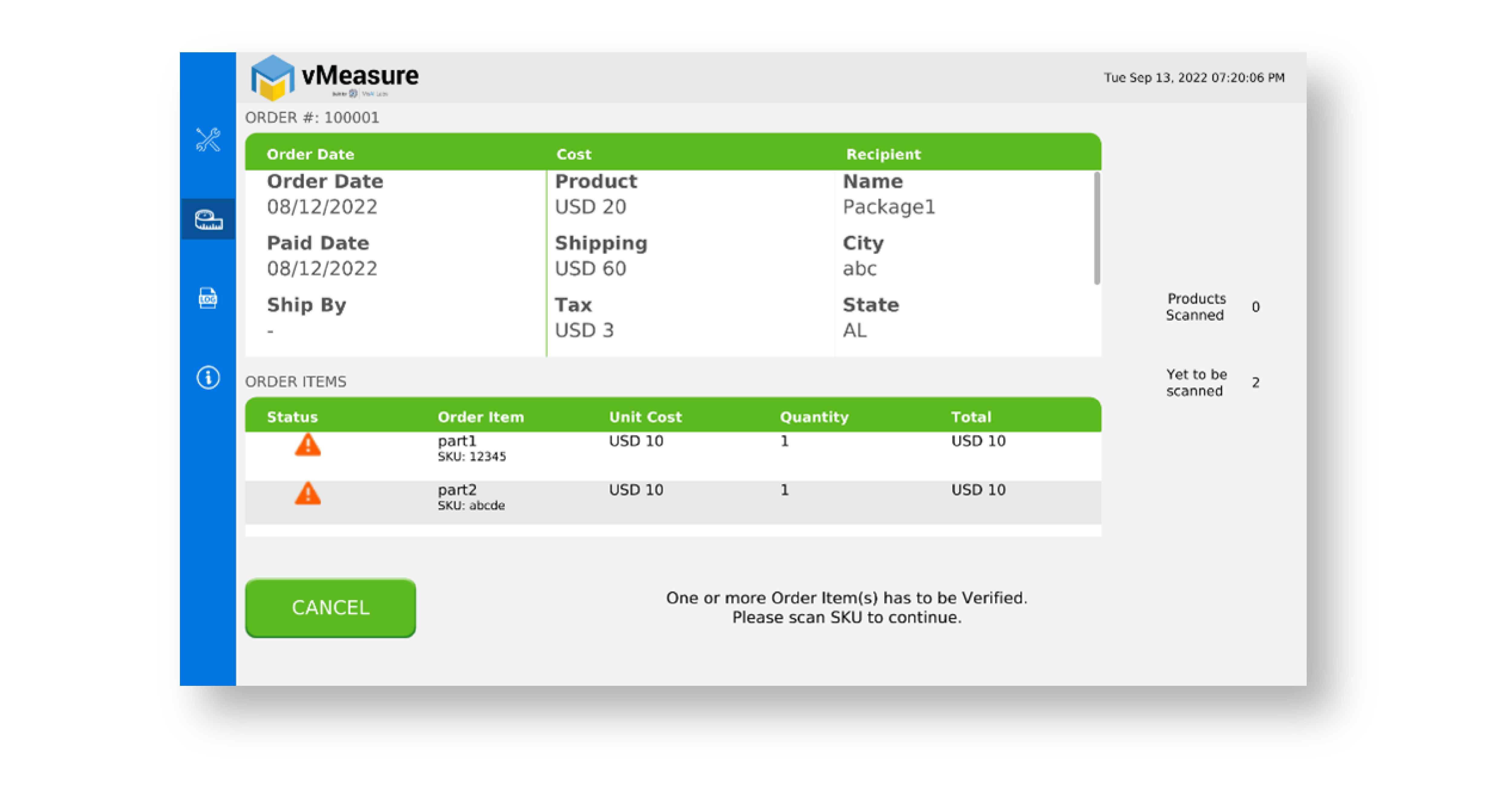

- The order details, along with the SKUs to be packed for the order, are displayed.

- The warehouse associate then scans the individual FNSKU to verify.

- Once all the items are verified using the FNSKU, the warehouse associate then packs the order and places the package on the vMeasure system.

- The warehouse associate scans the confirmation barcode to trigger the measurement on the vMeasure system.

- Once the measurement is triggered, the vMeasure system automatically dimensions the package and updates the corresponding data to Ship-Station

- The vMeasure system returns to the order ID scan screen automatically once the data upload to ShipStation is complete.

How did the client benefit from the vMeasure dimensioning machine?

- Business

- Operational

- Administrative

Truck ran on time leading to improved customer satisfaction

Improved quality control as the company had track of their parcels’ condition through the image capture feature

Reduced the time taken to allocate storage space

Boosted the company’s bottom line by reducing shipping costs with zero capital outlay

Reduced the truck loading time by 30%

Moving from manual to automated dimensioner improved the throughput rate at the point of inbound by 20%

Organize packages faster by using the right dims in the cartonization software

Lowered the efforts needed to dimension the parcel as it entered the warehouse

Reduced the time spent on carrier chargebacks as the team provided accurate DIMs

Protected the company against damage claims, as the parcel images served as proof

Improved worker productivity at the receiving dock

Enhanced the process and quality of records and data management as the data capture was automated

What makes vMeasure the only static parcel dimensioner

capable of solving your needs?

- Small SKU Mode

- All Parcel Mode

- White Goods Mode

- Mount Height

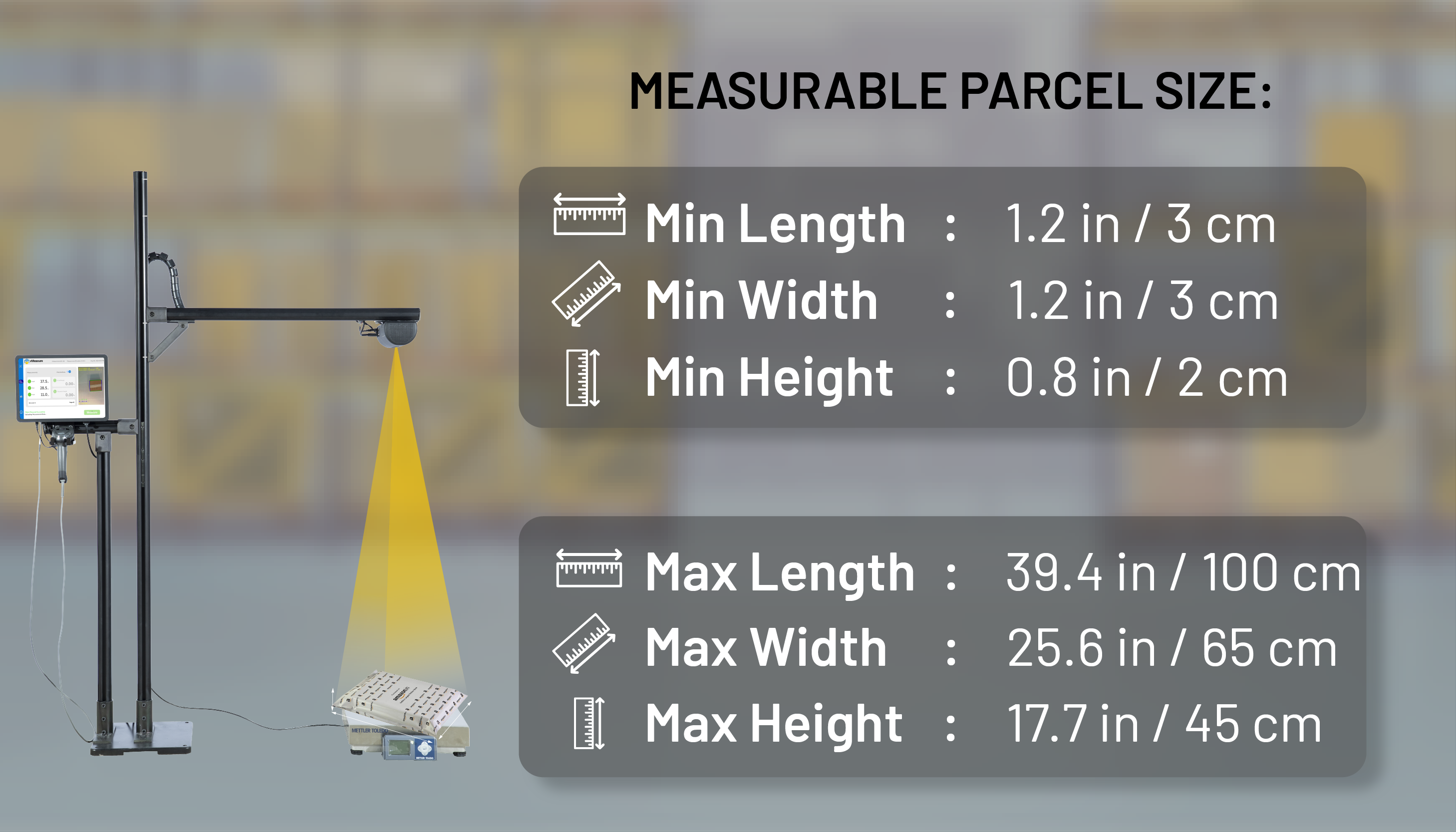

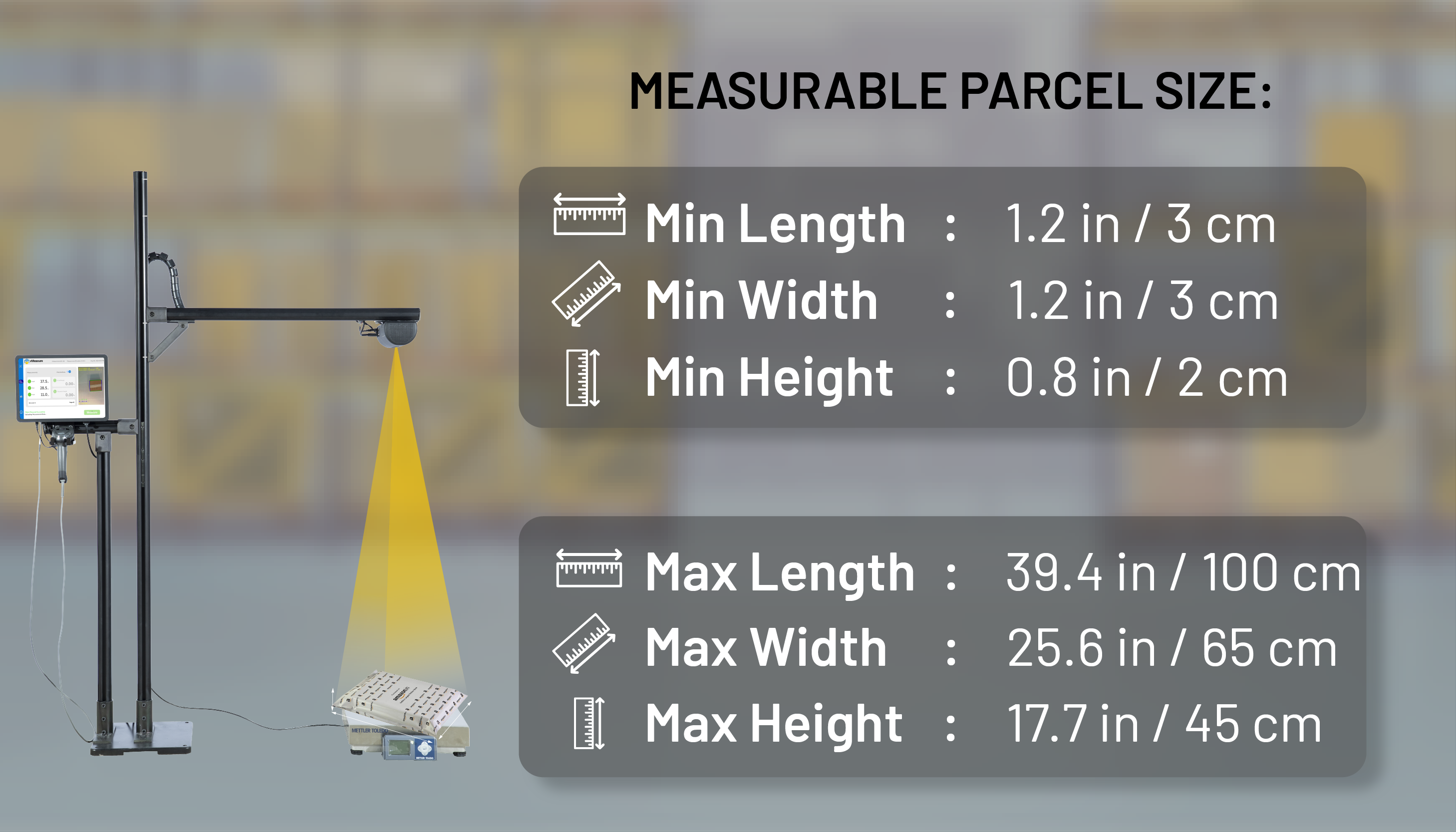

- Min and Max Measurable Size

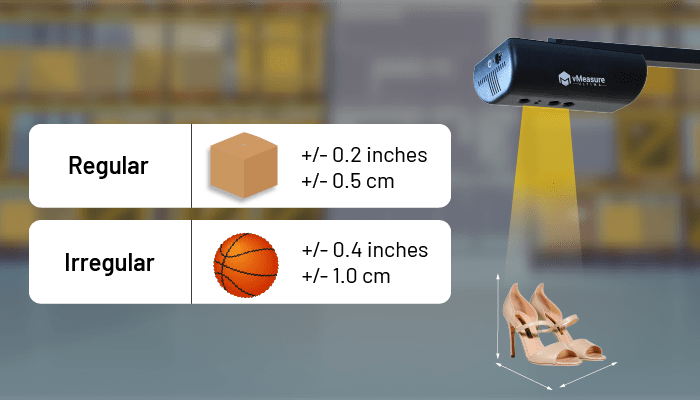

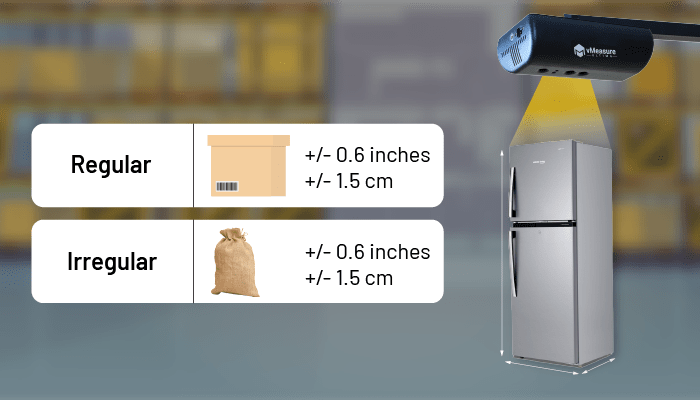

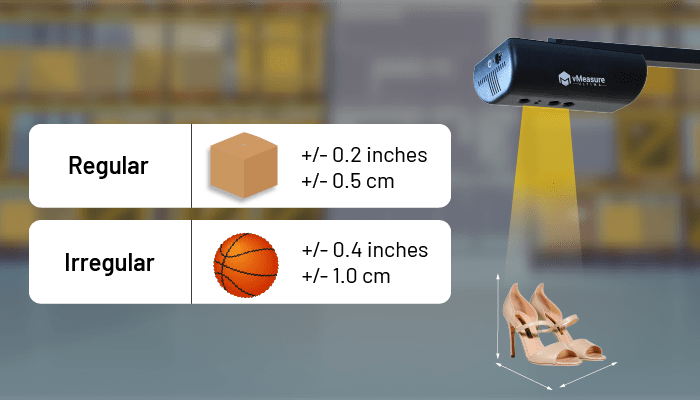

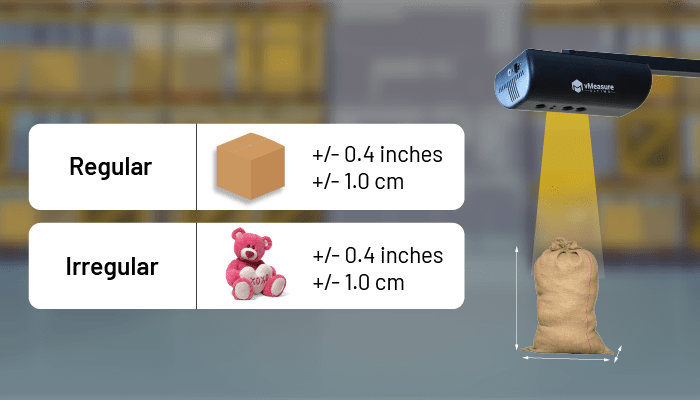

- Measuring Accuracy

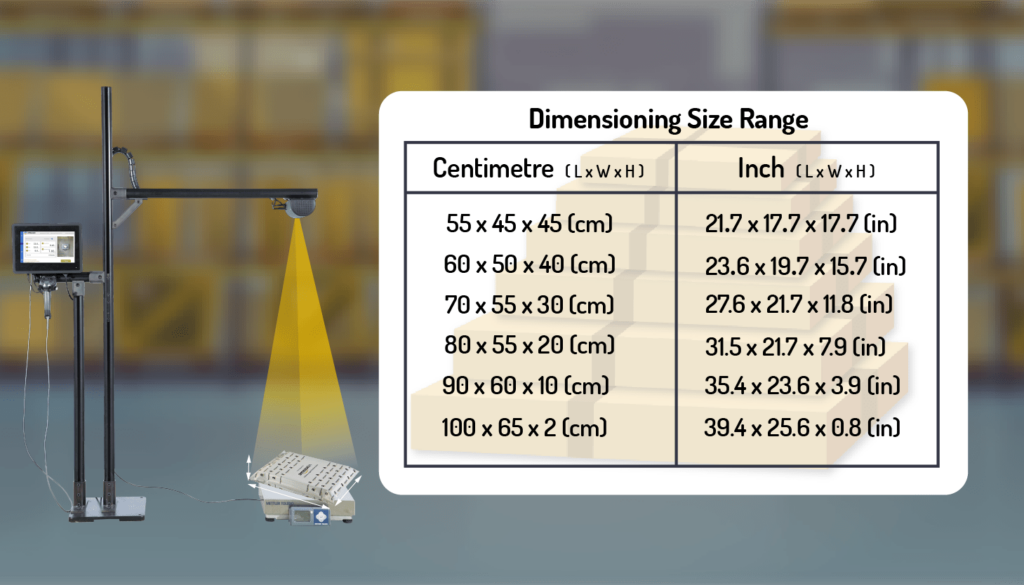

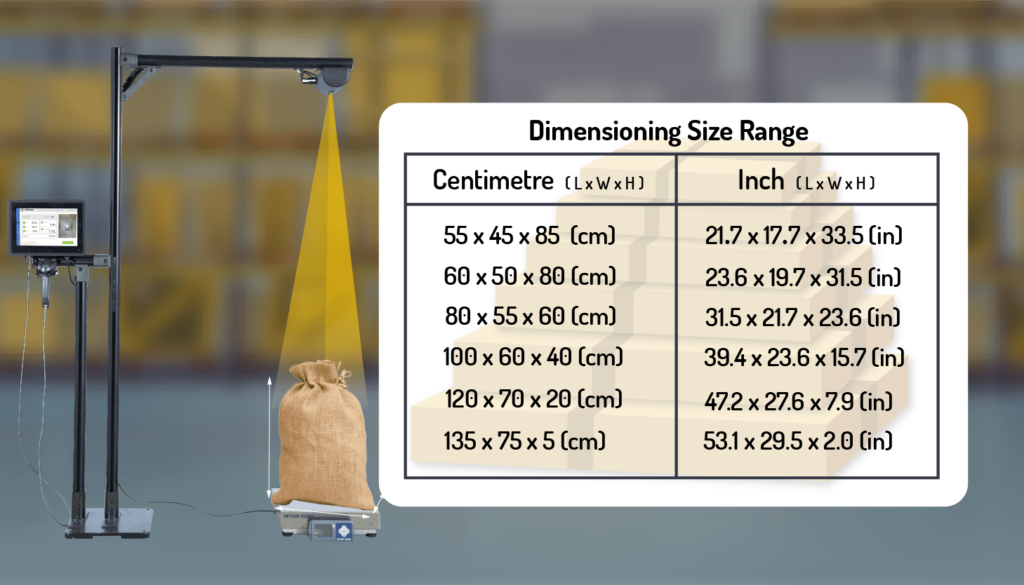

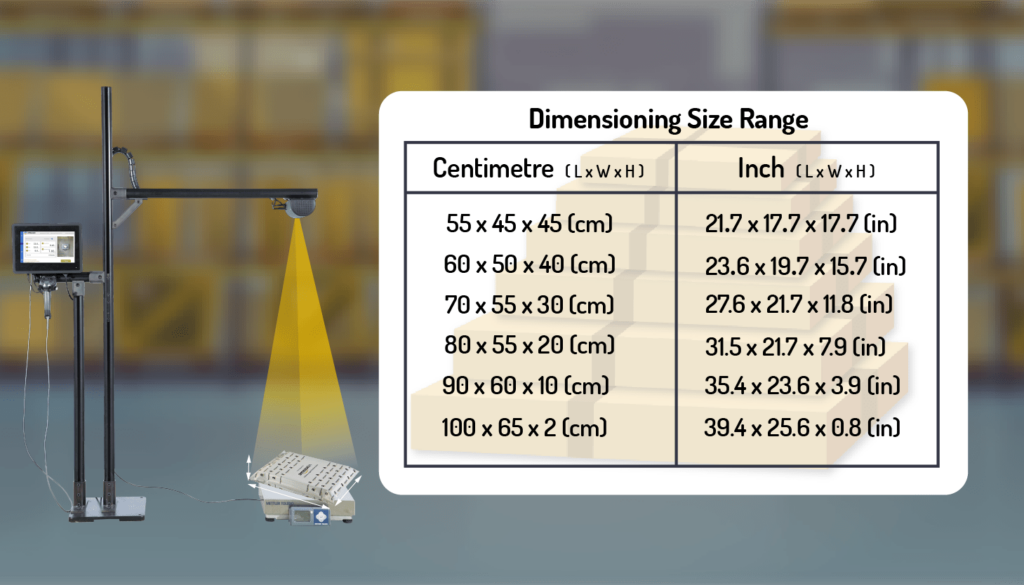

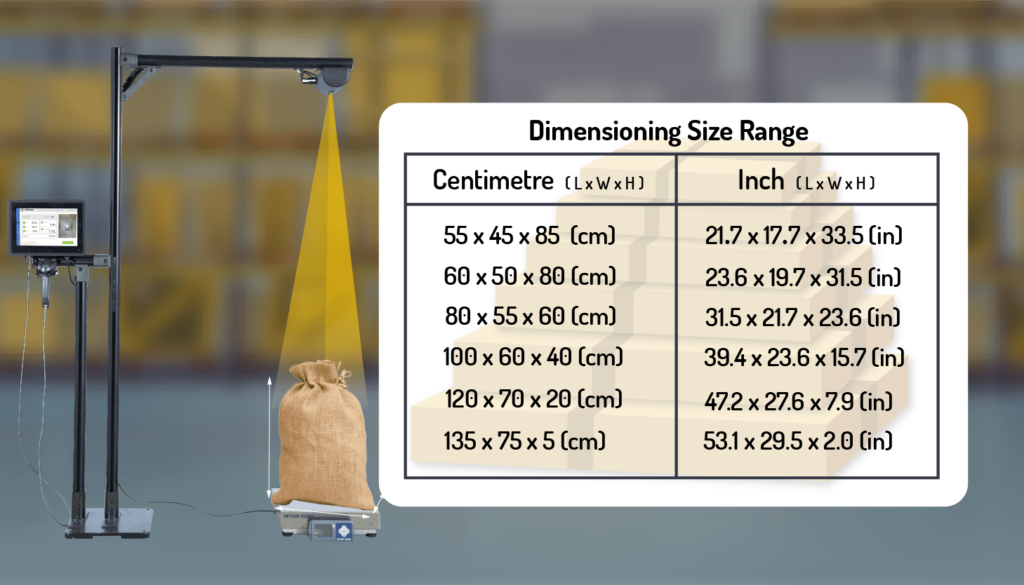

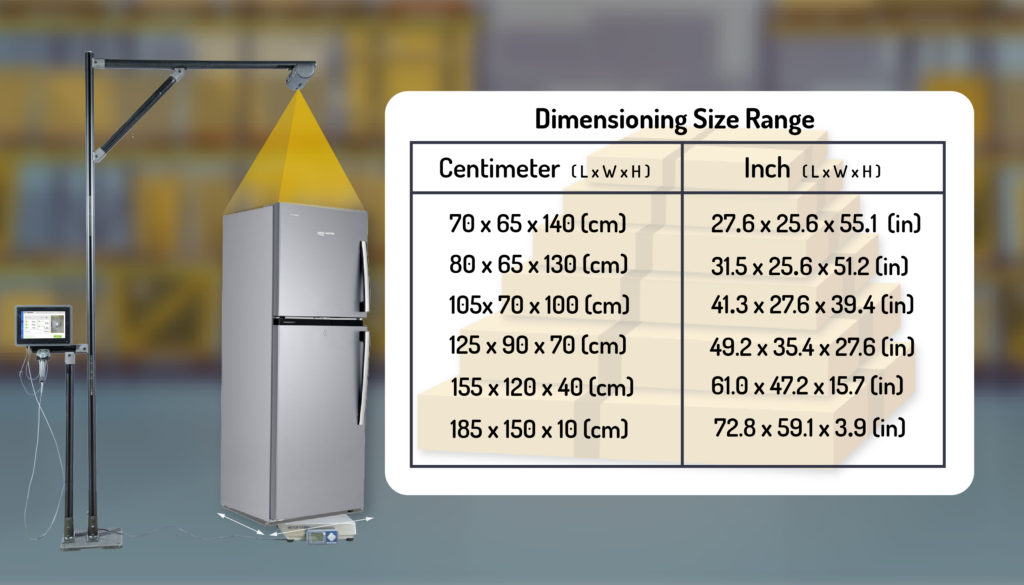

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

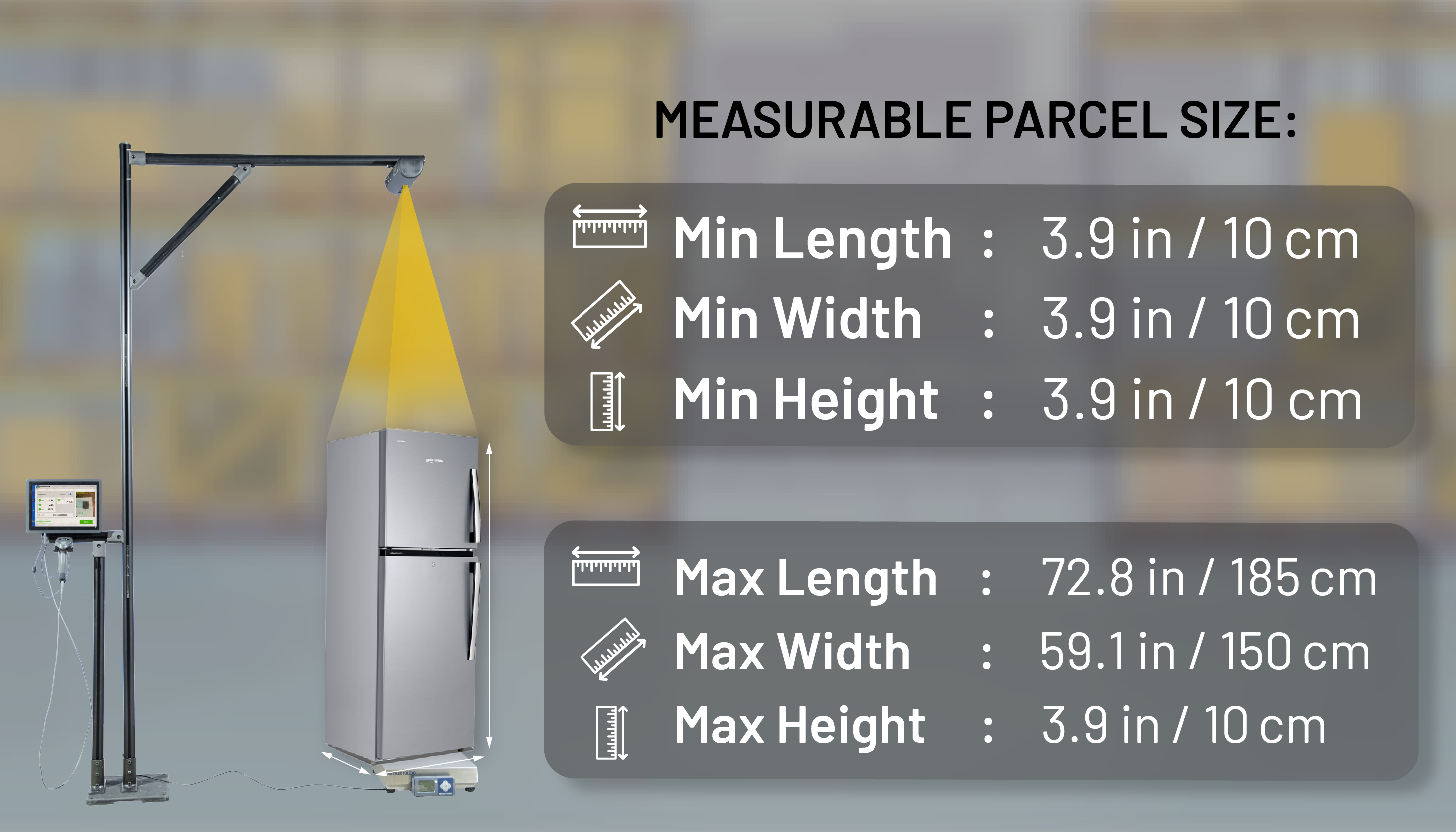

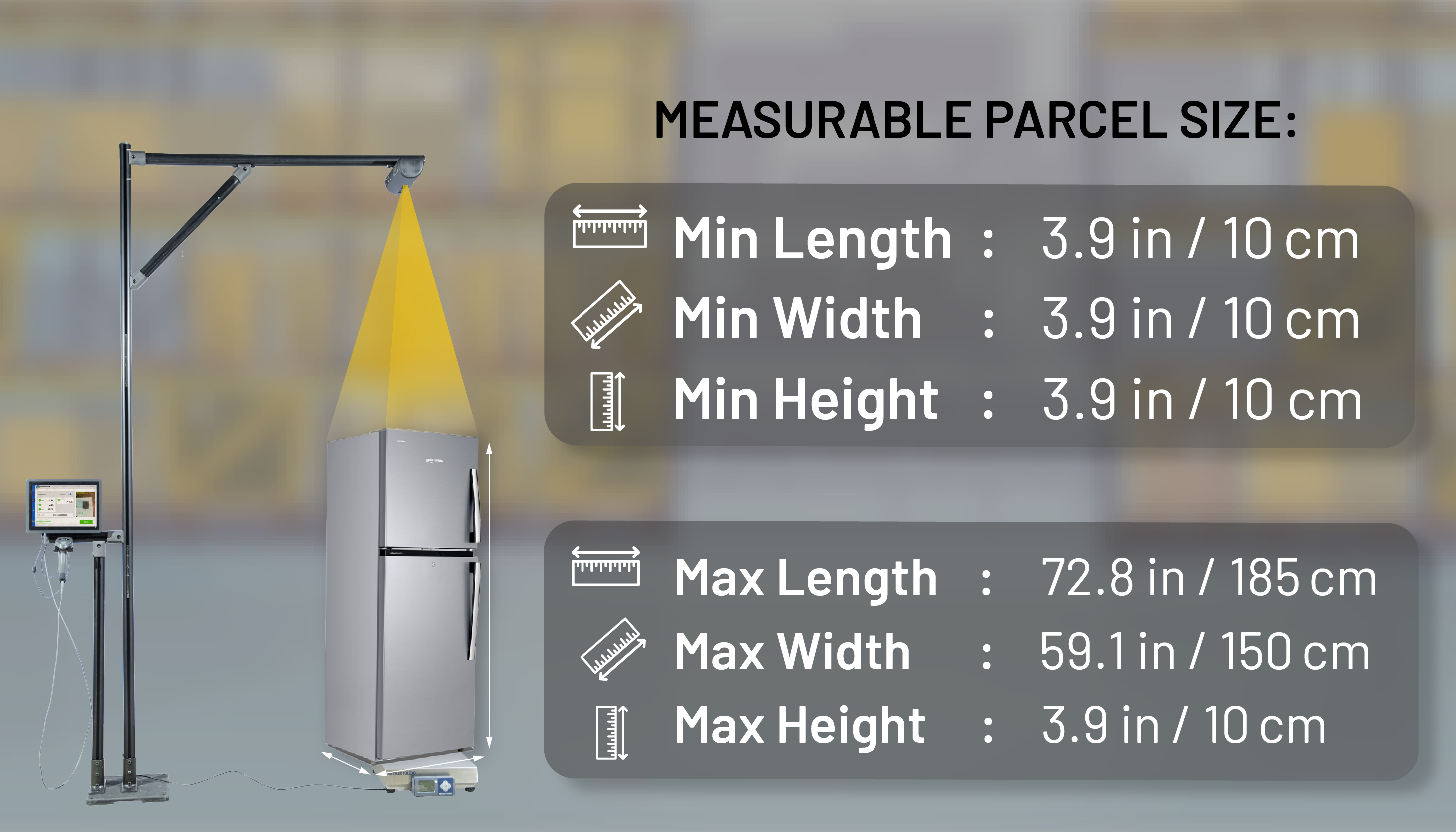

- Min and Max Measurable Size

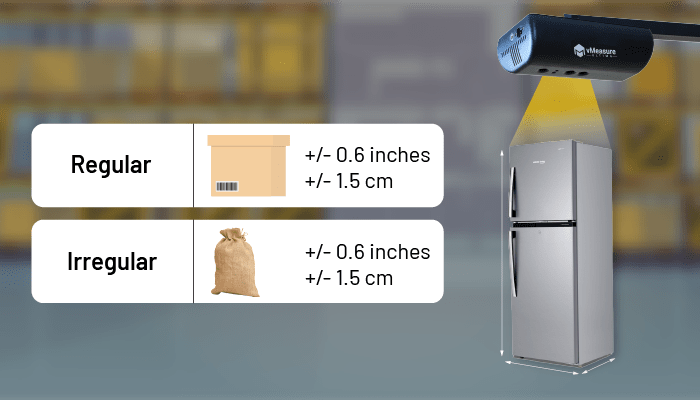

- Measuring Accuracy

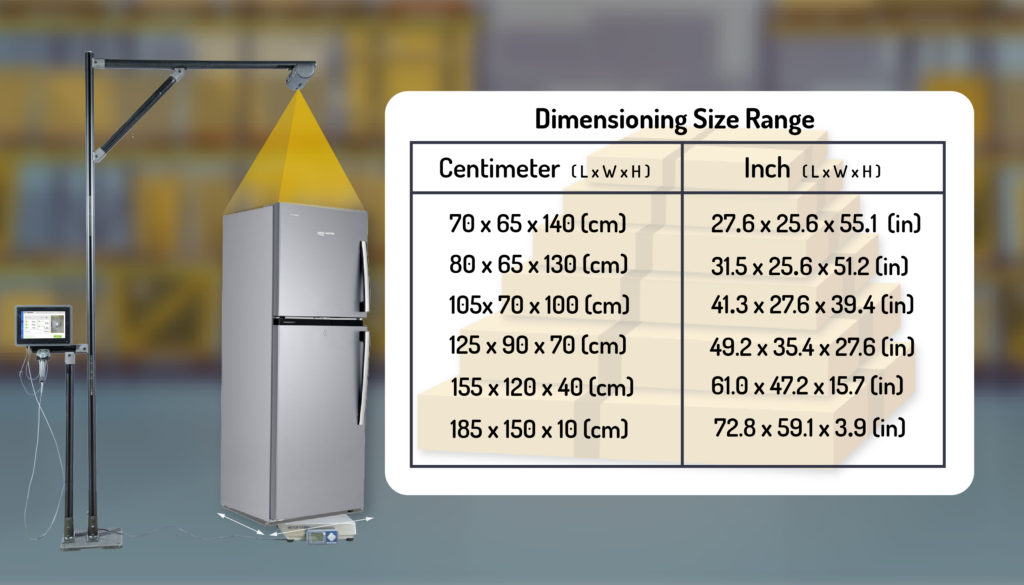

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

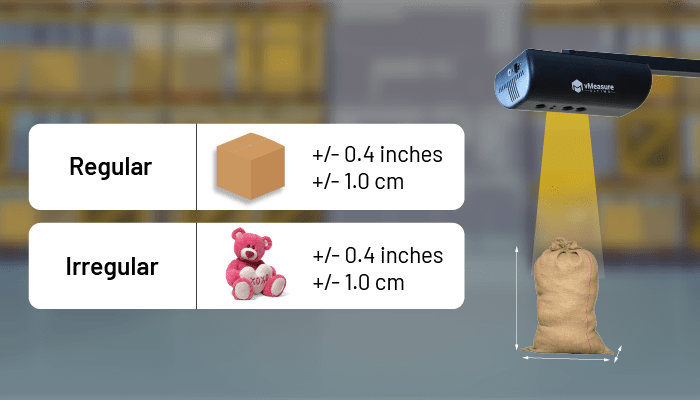

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods