How did vMeasure reduce an online books retailer’s shipping charges with the DesktopShipper’s native integration?

Industry

Product

Process

Use case

Integration

Case Study Summary

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

The manual dimensioning process stalled the growth of order throughput because it was time-consuming.

It was difficult to predict shipping costs as the company did not provide accurate dimensions which resulted in surcharges and penalties for not quoting the right dimensions.

The company could not decrease their shipping spend since the parcel dimensions were overstated most of the time.

The company couldn’t get their choice of carriers right since they had inaccurate dimensions which led to suboptimal carrier selection.

The management could not arrive upon a favourable contract between the carrier since they did not have accurate dimensions.

Despite having the DesktopShipper application that simplified the shipping label generation process, those labels were erroneous because the dimensions were still acquired from manual processes.

Maintenance and dissemination of data became difficult as most of the information were handwritten or partly digitized.

The DesktopShipper application simplified the company’s shipping process, yet the absence of accurate dimensions did not let them use the application to its fullest potential.

Difficulty in scaling up warehouse operations without significant increases in IT resources.

The manual dimensioning process stalled the growth of order throughput because it was time-consuming.

It was difficult to predict shipping costs as the company did not provide accurate dimensions which resulted in surcharges and penalties for not quoting the right dimensions.

The company could not decrease their shipping spend since the parcel dimensions were overstated most of the time.

The company couldn’t get their choice of carriers right since they had inaccurate dimensions which led to suboptimal carrier selection.

The management could not arrive upon a favourable contract between the carrier since they did not have accurate dimensions.

Despite having the DesktopShipper application that simplified the shipping label generation process, those labels were erroneous because the dimensions were still acquired from manual processes.

Maintenance and dissemination of data became difficult as most of the information were handwritten or partly digitized.

The DesktopShipper application simplified the company’s shipping process, yet the absence of accurate dimensions did not let them use the application to its fullest potential.

Difficulty in scaling up warehouse operations without significant increases in IT resources.

Why do customers choose vMeasure dimensional weighing system

over other dimensioners?

- Dimensioning Capabilities

- Native Integration with DesktopShipper

- Software Integration

- Physical Characteristics

vMeasure covered almost 95% of the product/SKU sizes which were dimensioned within <1 second.

The device can measure SKUs in any orientation given that they were inside the camera’s FOV (Field of Vision).

vMeasure was natively integrated with DesktopShipper which simplified the company’s dimensioning and rate-shopping experience.

The operator performed both the dimensioning and the carrier selection from within the DesktopShipper’s application

vMeasure team enabled a seamless integration with DesktopShipper with minimal customer-side IT support.

A configurable default data was built instead of sending “NA” values in case of a failed measurement.

vMeasure Parcel Ultima took less space in their outbound station, enabling them to make more productive use of the space.

The device came with minimal parts and can be installed in 15 – 20 minutes.

vMeasure covered almost 95% of the product/SKU sizes which were dimensioned within <1 second.

The device can measure SKUs in any orientation given that they were inside the camera’s FOV (Field of Vision).

vMeasure was natively integrated with DesktopShipper which simplified the company’s dimensioning and rate-shopping experience.

The operator performed both the dimensioning and the carrier selection from within the DesktopShipper’s application

vMeasure team enabled a seamless integration with DesktopShipper with minimal customer-side IT support.

A configurable default data was built instead of sending “NA” values in case of a failed measurement.

vMeasure Parcel Ultima took less space in their outbound station, enabling them to make more productive use of the space.

The device came with minimal parts and can be installed in 15 – 20 minutes.

How did the client benefit from vMeasure dimensional weighing system?

- Business

- Operational

- Administrative

The company’s profitability increased because of cost-reduction in packaging, labor, and shipping.

With accurate dimensions, the shipping costs reduced as the company knew exactly what they were paying for.

The shipping costs became predictable, and the management were able to efficiently plan their working capital.

The management was able to handle increasing volumes and adapt to the changing business needs as they enhanced their order fulfilment productivity.

The addition of vMeasure enhanced the dimensioning speed at the outbound station.

vMeasure’s native integration with DesktopShipper simplified their dimensioning and carrier selection workflow since everything was done through the DesktopShipper UI.

The logistics team was able to get better terms with the carriers because they provided accurate dimensions.

Order throughput increased since vMeasure eliminated all the superfluous steps involved with dimensioning.

The admin team found it easy to prepare shipping documentation with no errors since all the required information was available on the DesktopShipper’s application along with accurate dimensions taken with vMeasure.

The integration improved the accuracy of shipping labels which kept shipping errors to a minimum.

vMeasure + DesktopShipper integration eliminated the risk of chargebacks which saved significant time that could have otherwise been wasted on resolving disputes.

The parcel image capture feature served as a proof in case of any carrier chargebacks or penalties.

What makes vMeasure the only vMeasure dimensional weighing system

capable of solving your needs?

Check out the complete dimensioning range in the interactive below

- Small SKU Mode

- All Parcel Mode

- White Goods Mode

- Mount Height

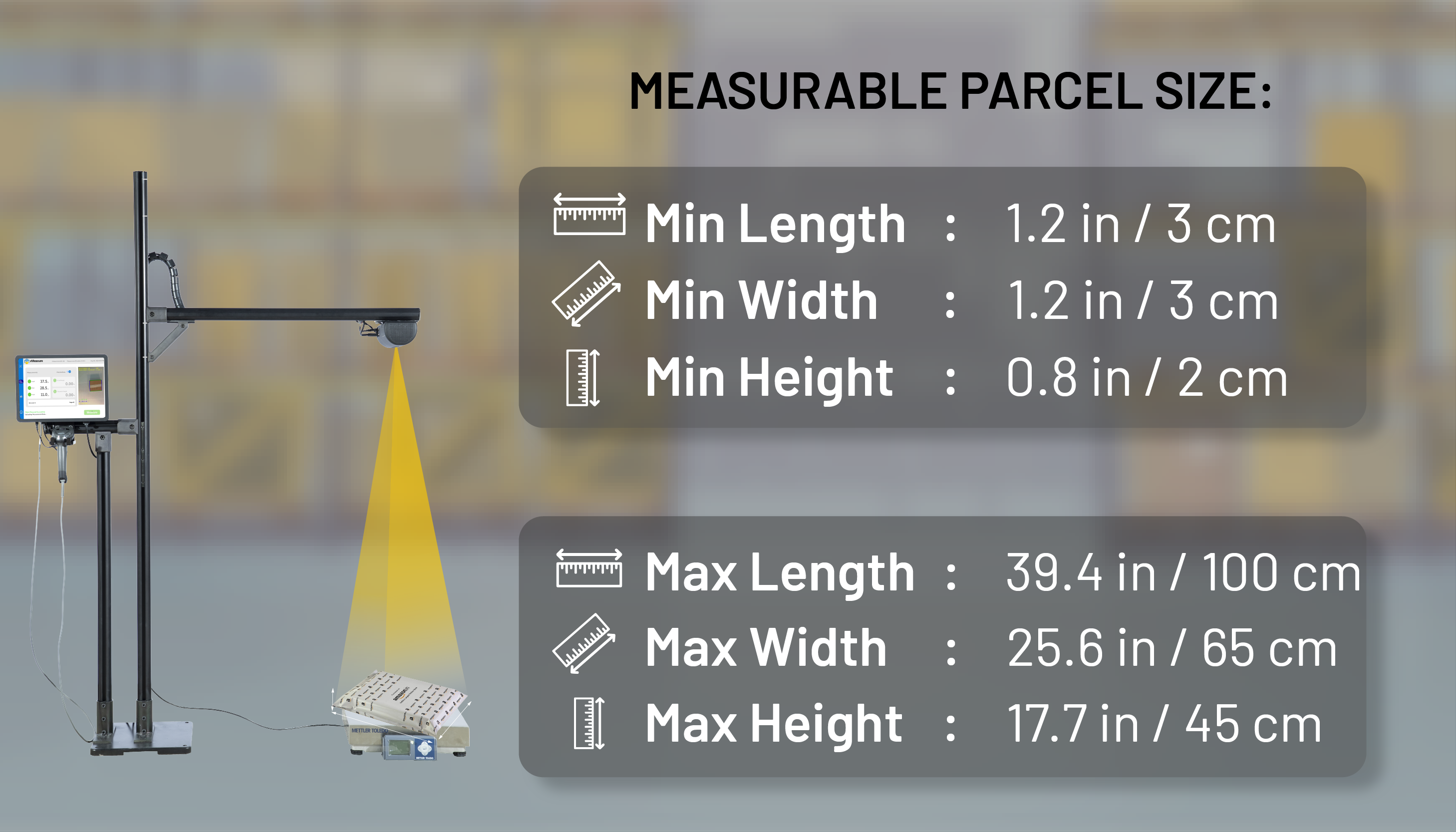

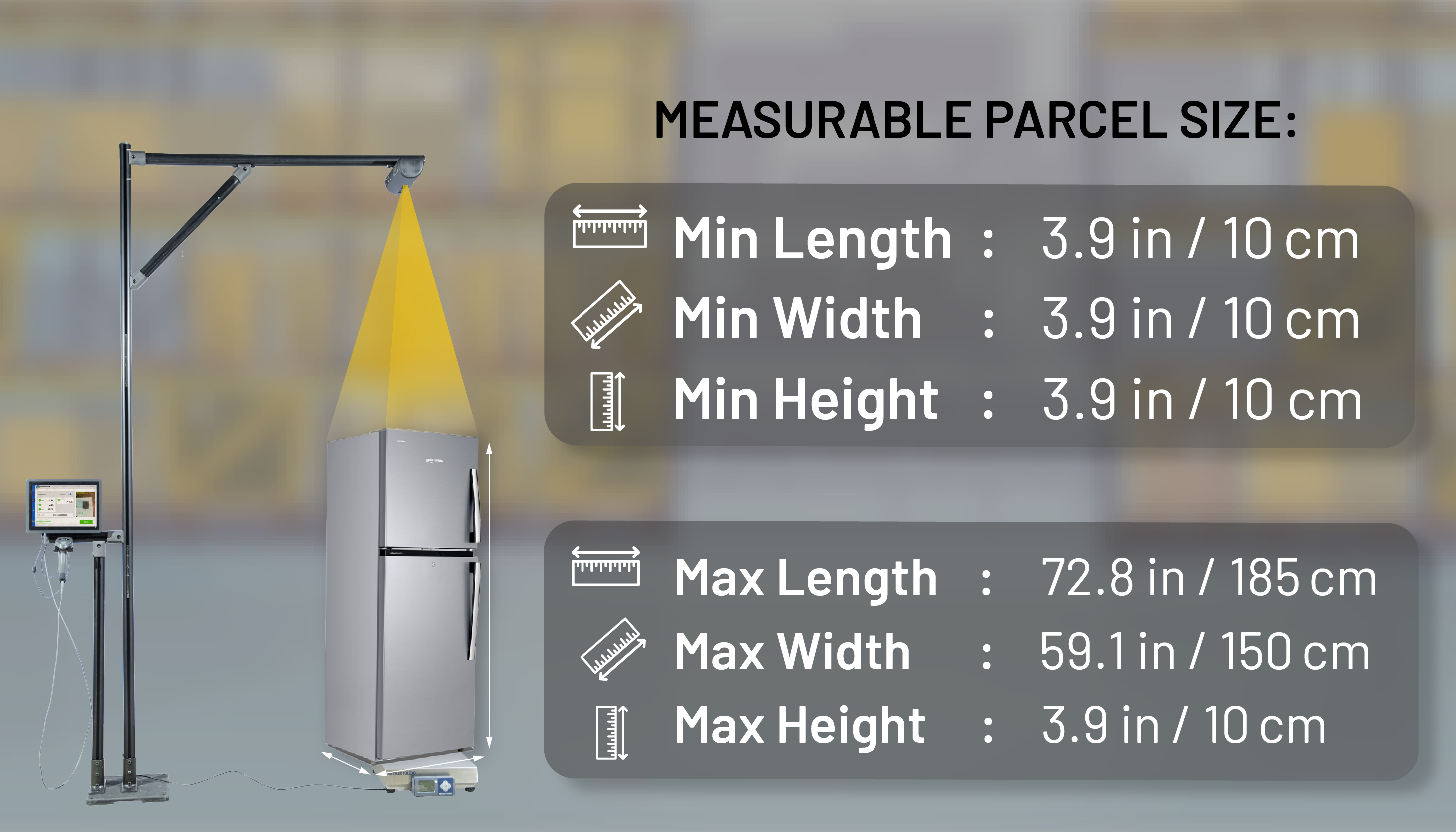

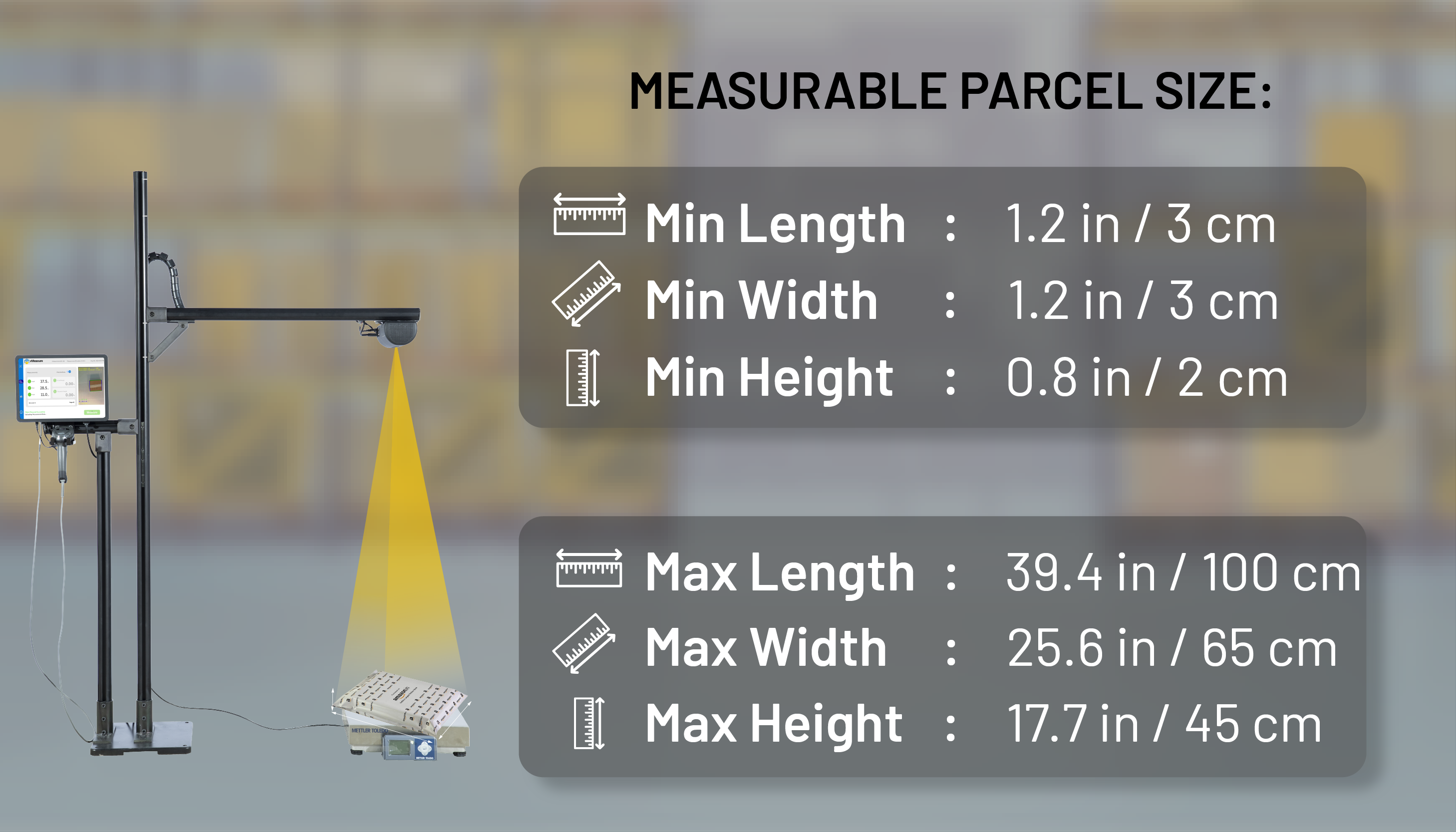

- Min and Max Measurable Size

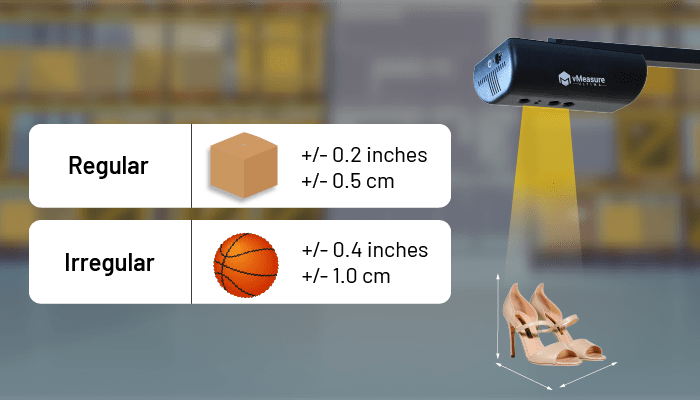

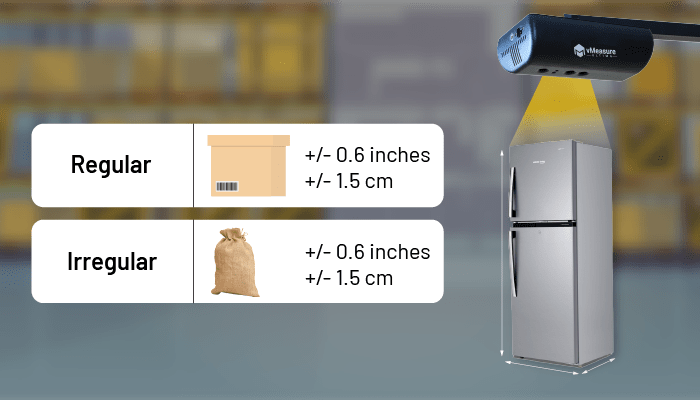

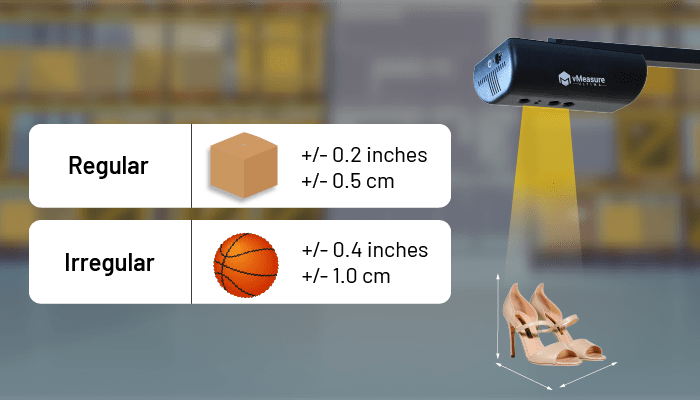

- Measuring Accuracy

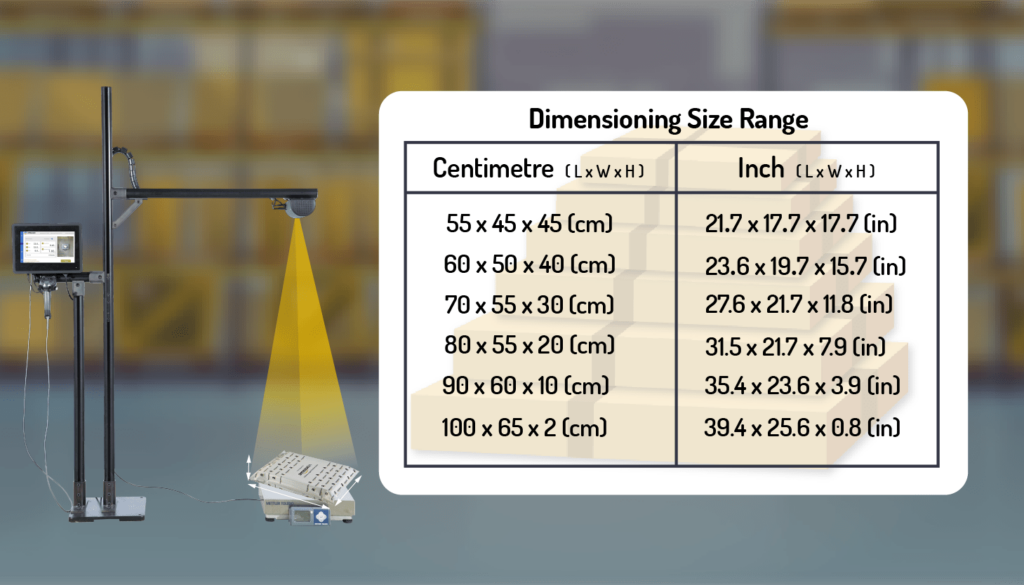

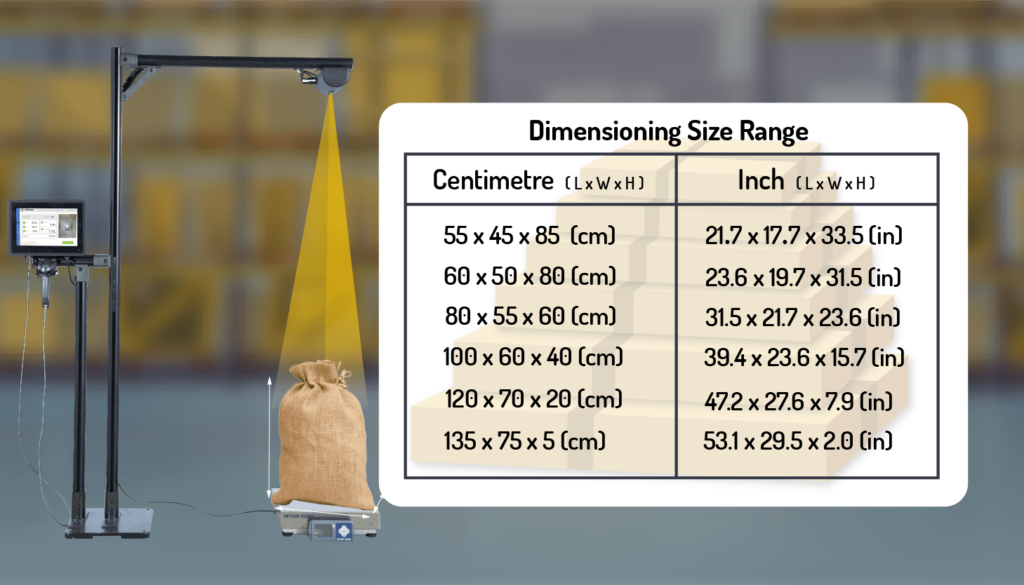

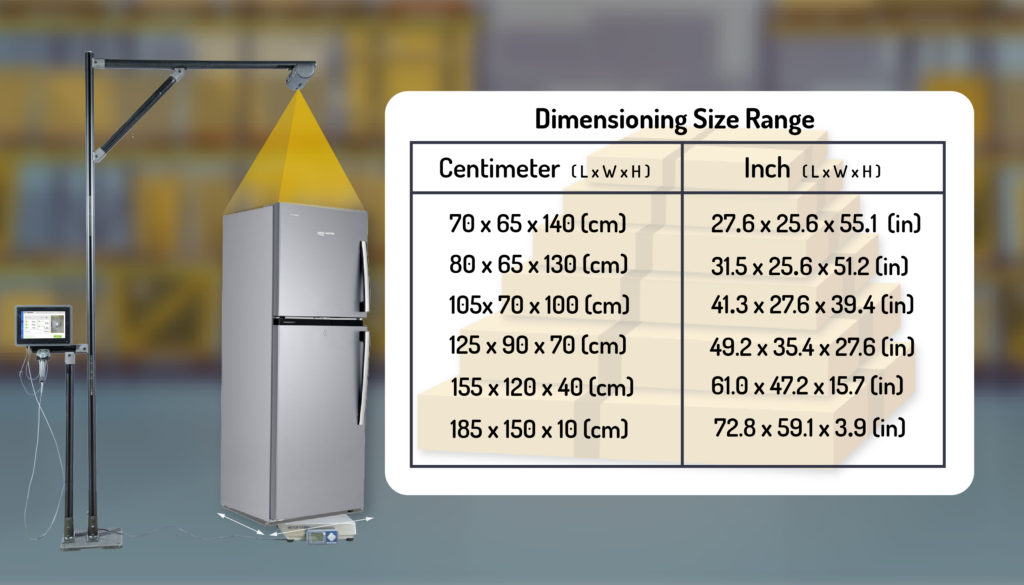

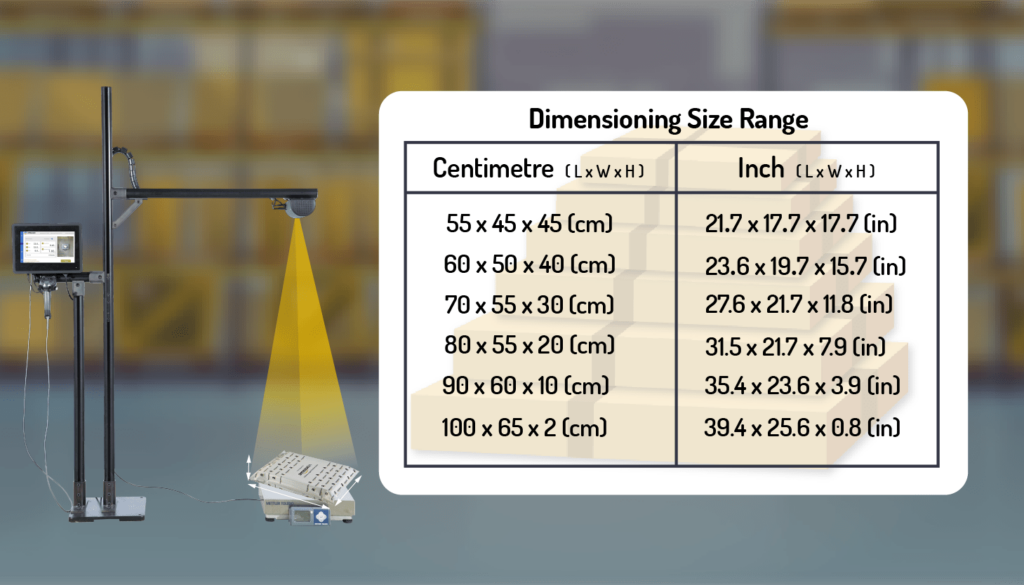

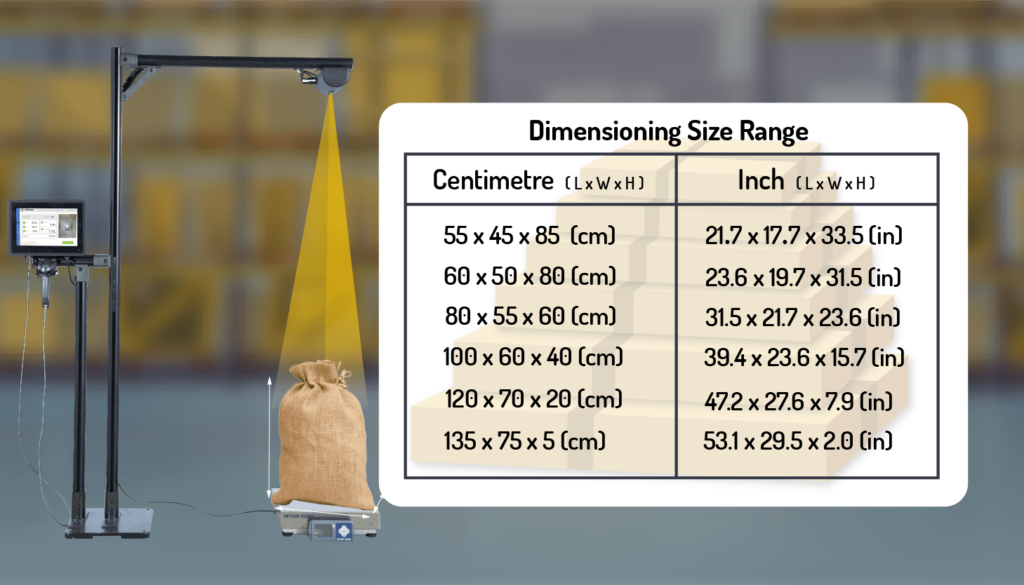

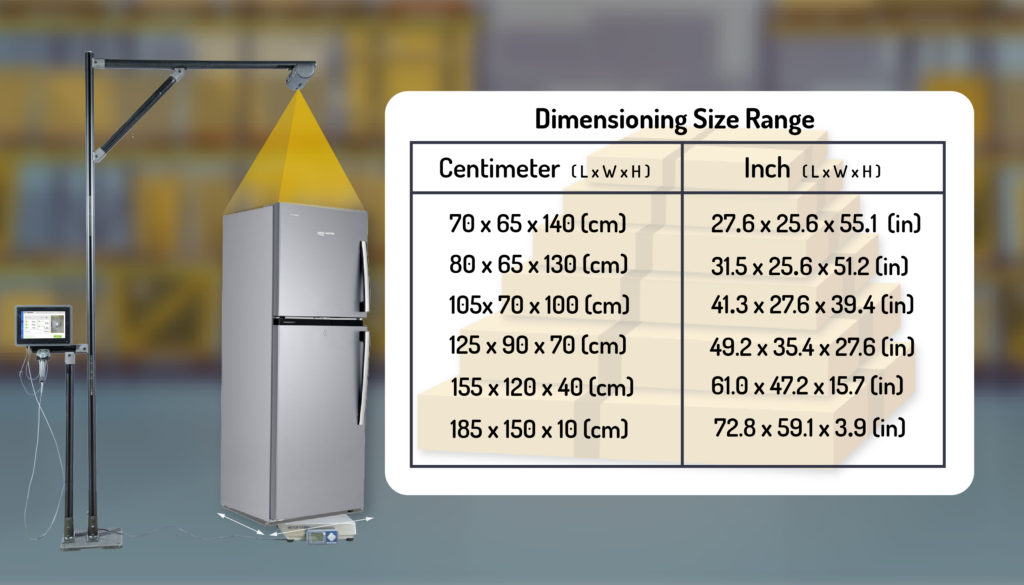

- Dimensioning Size Range

- Additional Data Capture

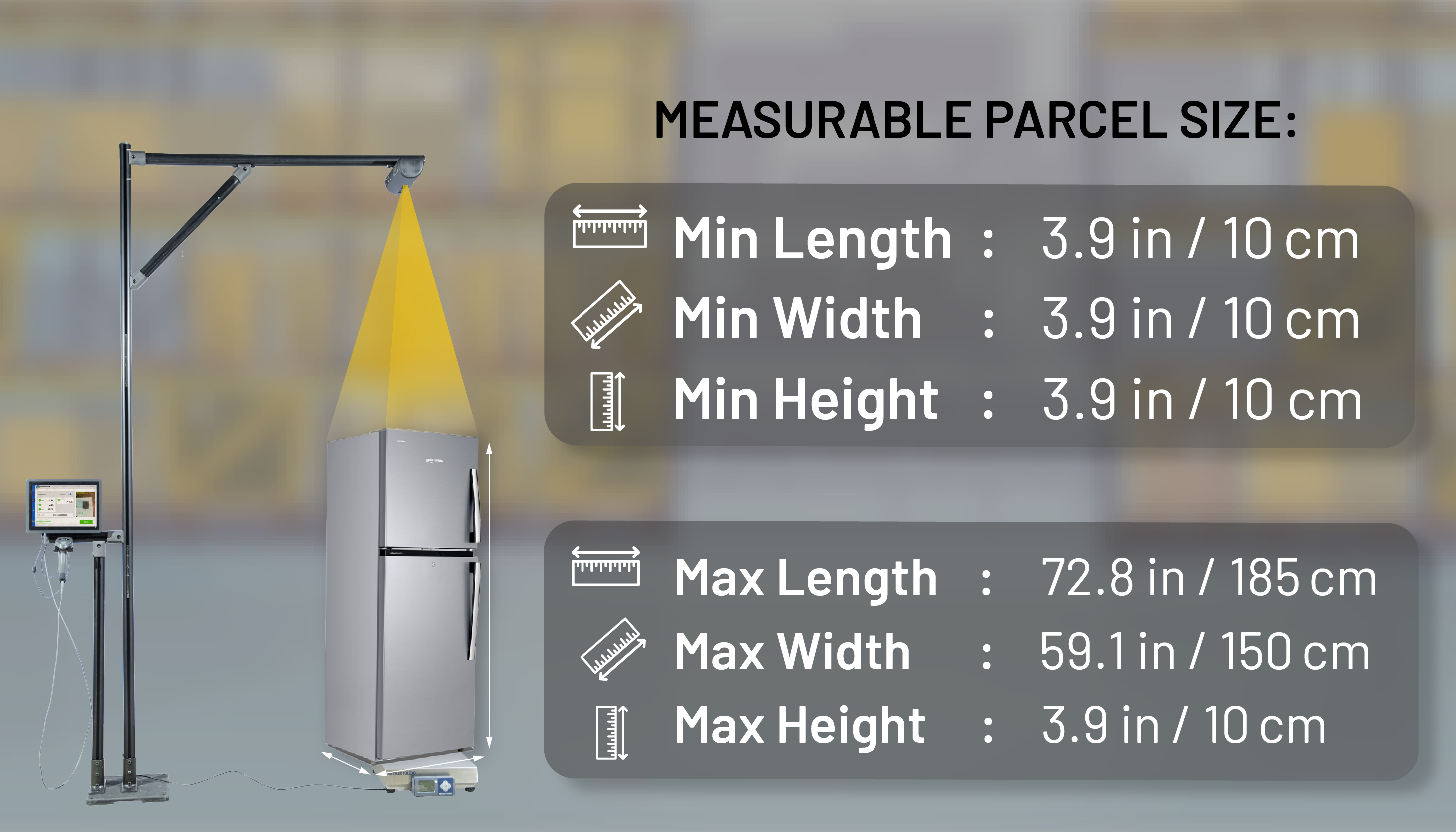

- Mount Height

- Min and Max Measurable Size

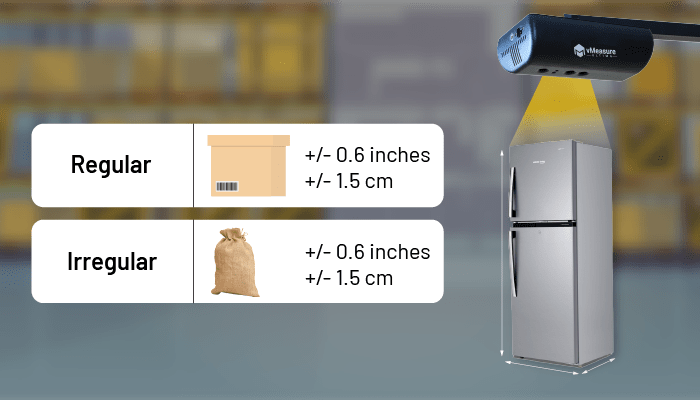

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

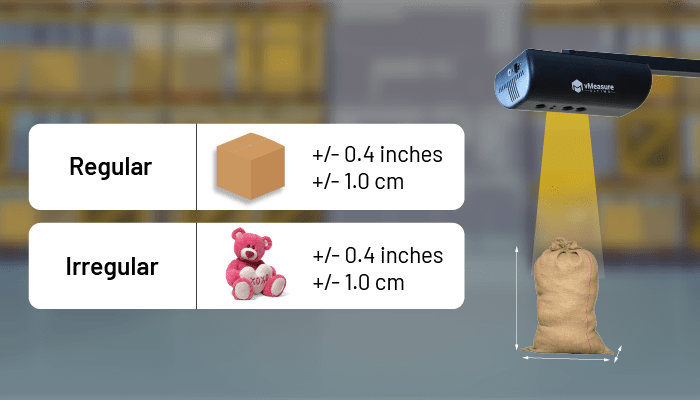

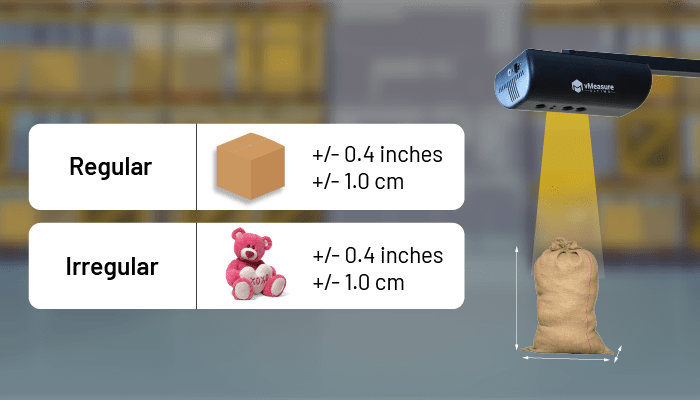

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods