How did a fulfillment center improve the throughput rate by replacing manual dimensioning with automated dimensioning & custom workflows?

Industry

Product

Process

Use case

Integration

Case Study Summary

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

Sometimes, wrong parcels were shipped to the customersbecause the orders got mixed up at the packing station. This impacted customer satisfaction.

Low picking efficiency arising from improper slotting mechanism transformed into low throughput at the packing station.

The dimensioning flow was inefficient as it was manual, and the dimensioning system did not have features to expedite their workflow.

The old dimensioner’s design was very bulky. It took up a lot of space in the packing station, restricting movements and decreasing productivity.

The current dimensioning solutions couldn’t keep up with the company’s dimensioning workflow due to a lack of customizable workflows.

The IT team could not support the logistics team with complex integrations.

They could not find a suitable dimensioning solution that seamlessly integrates with the company’s WMS.

Sometimes, wrong parcels were shipped to the customersbecause the orders got mixed up at the packing station. This impacted customer satisfaction.

Low picking efficiency arising from improper slotting mechanism transformed into low throughput at the packing station.

The dimensioning flow was inefficient as it was manual, and the dimensioning system did not have features to expedite their workflow.

The old dimensioner’s design was very bulky. It took up a lot of space in the packing station, restricting movements and decreasing productivity.

The current dimensioning solutions couldn’t keep up with the company’s dimensioning workflow due to a lack of customizable workflows.

The IT team could not support the logistics team with complex integrations.

They could not find a suitable dimensioning solution that seamlessly integrates with the company’s WMS.

Why did the customer choose vMeasure dimensional scanner

over other dimensioners?

- Dimensioning Capability

- Software Integration

- Hardware Customization

- Physical Characteristics

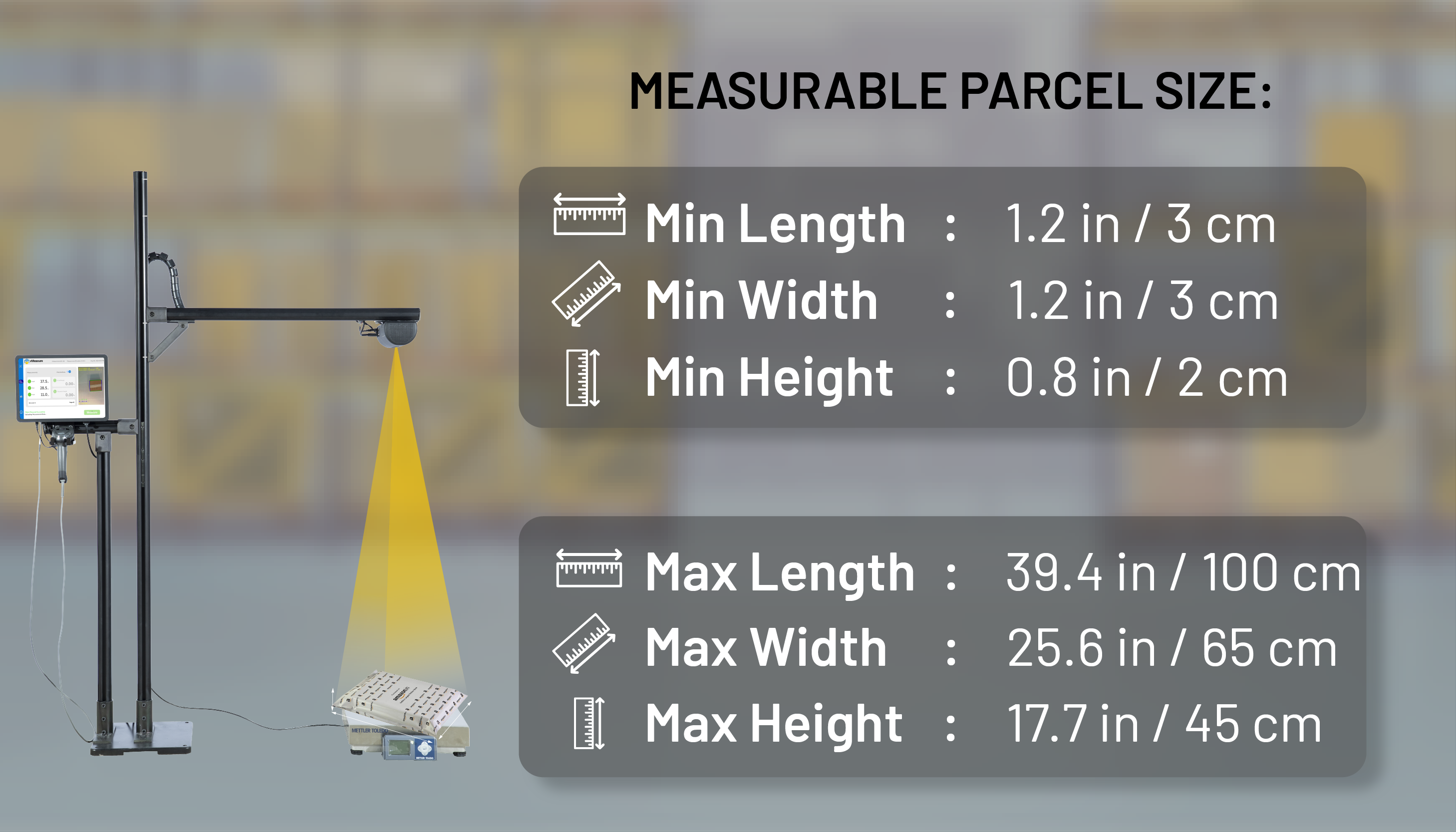

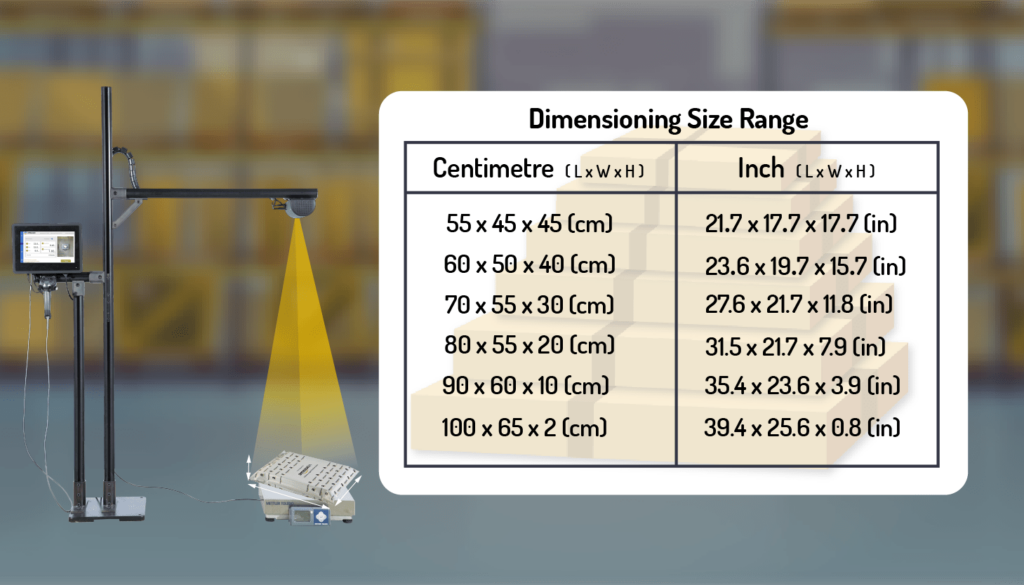

vMeasure dimensional scanner covered all the product/SKU sizes which need to be dimensioned within <1 sec

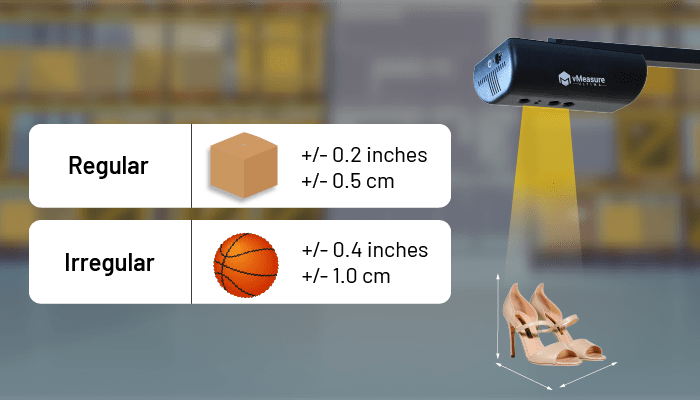

The accuracy and repeatability metrics aligned with the Operations teams’ expectations.

The vMeasure team built customizable workflows that included features like Barcode Validation using Regex pattern and Webhook Payload Customization.

vMeasure was able to integrate with the client’s WMS without needing heavy lifting from their IT team.

The mount design was customized by changing the touchscreen display orientation in the direction of the Vision Head Unit.

The vMeasure device was integrated with the client’s preferred weighing scale.

vMeasure dimensional scanner was small and compact, leaving more space for the warehouse worker to move freely.

The device was very simple to install within 15 – 20 minutes and had minimal parts.

vMeasure dimensional scanner covered all the product/SKU sizes which need to be dimensioned within <1 sec

The accuracy and repeatability metrics aligned with the Operations teams’ expectations.

The vMeasure team built customizable workflows that included features like Barcode Validation using Regex pattern and Webhook Payload Customization.

vMeasure was able to integrate with the client’s WMS without needing heavy lifting from their IT team.

The mount design was customized by changing the touchscreen display orientation in the direction of the Vision Head Unit.

The vMeasure device was integrated with the client’s preferred weighing scale.

vMeasure dimensional scanner was small and compact, leaving more space for the warehouse worker to move freely.

The device was very simple to install within 15 – 20 minutes and had minimal parts.

The vMeasure Dimensioning Solution

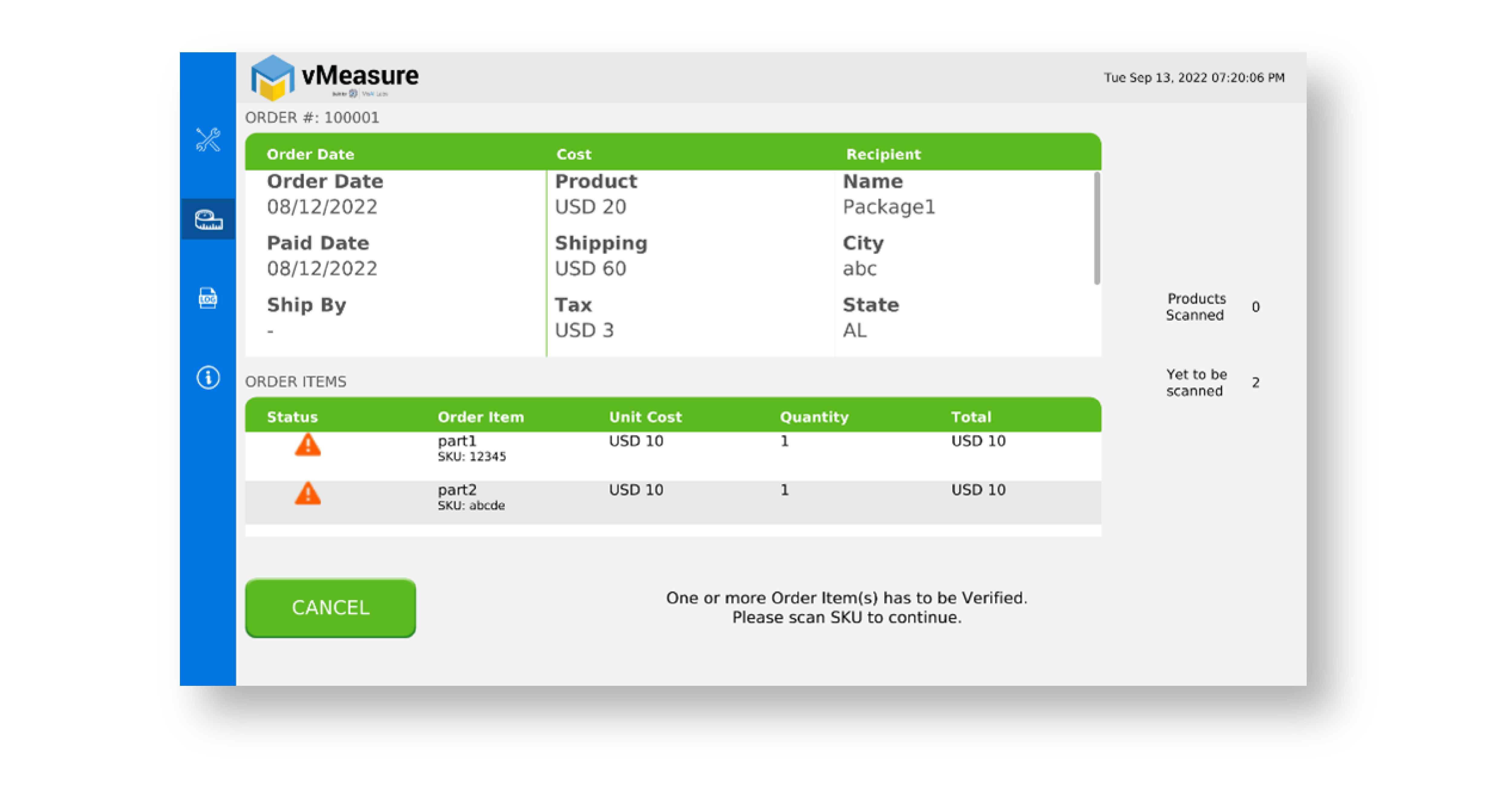

- The order details, along with the SKUs to be packed for the order, are displayed.

- The warehouse associate then scans the individual FNSKU to verify.

- Once all the items are verified using the FNSKU, the warehouse associate then packs the order and places the package on the vMeasure system.

- The warehouse associate scans the confirmation barcode to trigger the measurement on the vMeasure system.

- Once the measurement is triggered, the vMeasure system automatically dimensions the package and updates the corresponding data to Ship-Station

- The vMeasure system returns to the order ID scan screen automatically once the data upload to ShipStation is complete.

How did the client benefit from vMeasure dimensional scanner?

- Business

- Operational

- Administrative

The order dispatch accuracy increased tremendously, and more orders went on time, resulting in happier customers.

The company transitioned from purchasing a dimensioner on a CapEx basis to an OpEx basis because of vMeasure.

vMeasure boosted the company’s bottom line by reducing shipping costs with zero capital outlay.

As more orders went out, no orders were left idle, taking up crucial space.

Parcel audit was possible because of the image capture feature.

Warehouse workers took less time to dimension and did not have to manually upload the measurement data to their WMS, saving time and improving efficiency.

The customizable workflows coalesced with the company’s outbound flow and improved data capture.

vMeasure’s compact design was more ergonomically friendly than the old dimensioner. Thus, the workers did not exert much to measure parcels, and their speed automatically improved.

The labor allocation was focused on high-value activities since the dimensioning process was automated.

The parcel images served as proof against damage claims.

Workers felt it was less straining to push the data into the WMS as the process was automated by vMeasure, resulting in less fatigue and high morale.

The quality of data collected at all pack stations improved and felt more organized for later consideration by the decision-makers.

What makes vMeasure the only vMeasure dimensional scanner

capable of solving your needs?

- Small SKU Mode

- All Parcel Mode

- White Goods Mode

- Mount Height

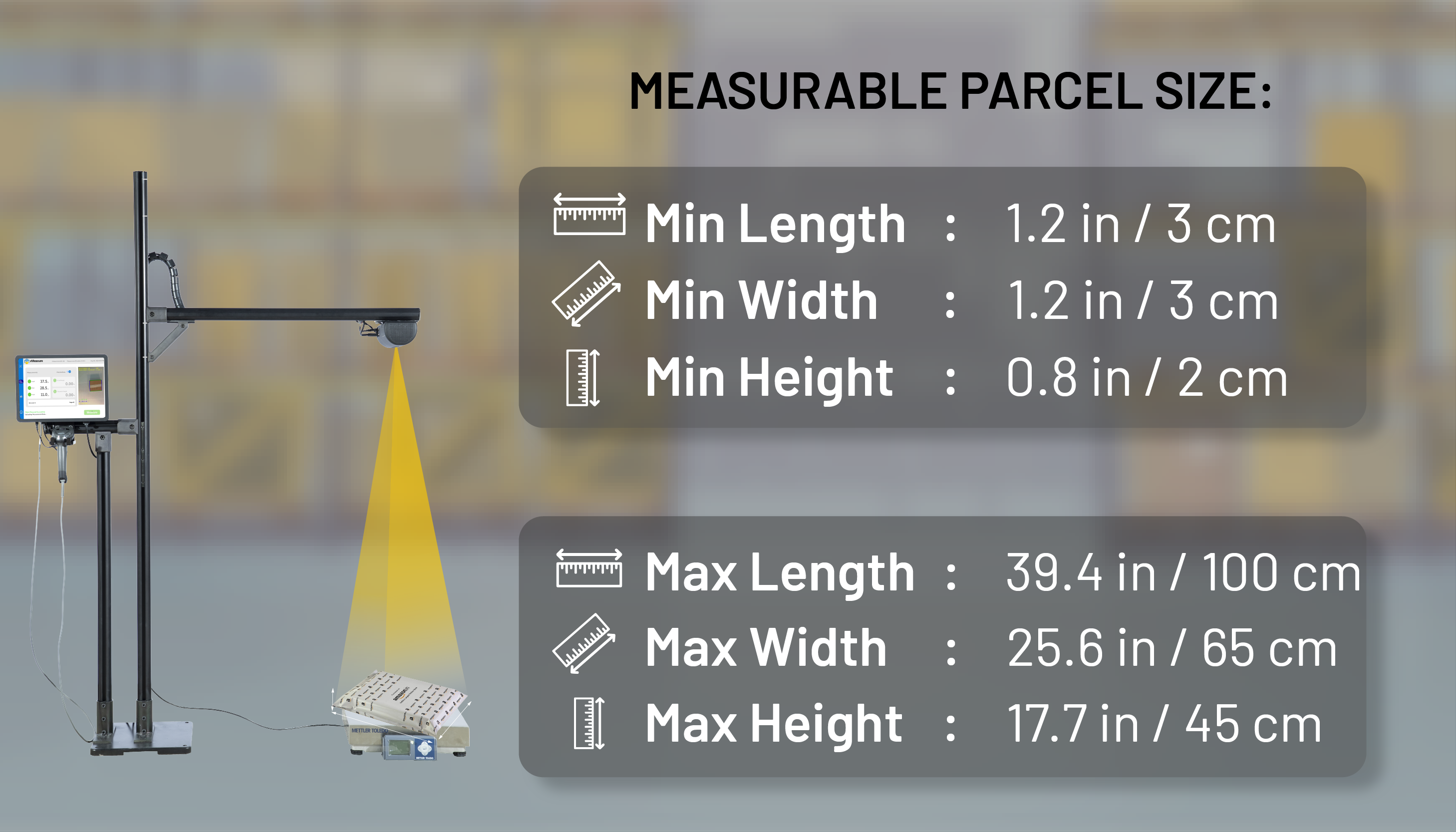

- Min and Max Measurable Size

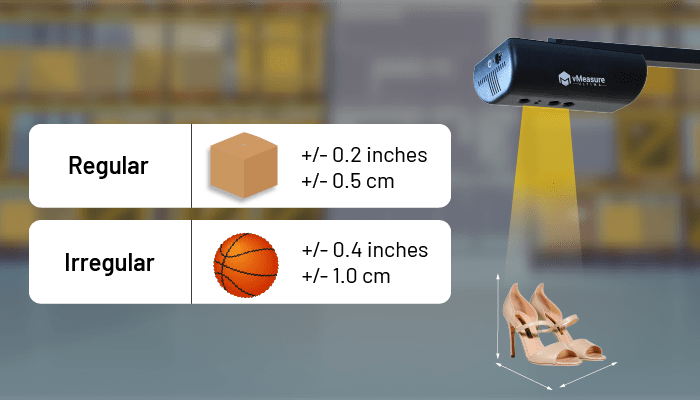

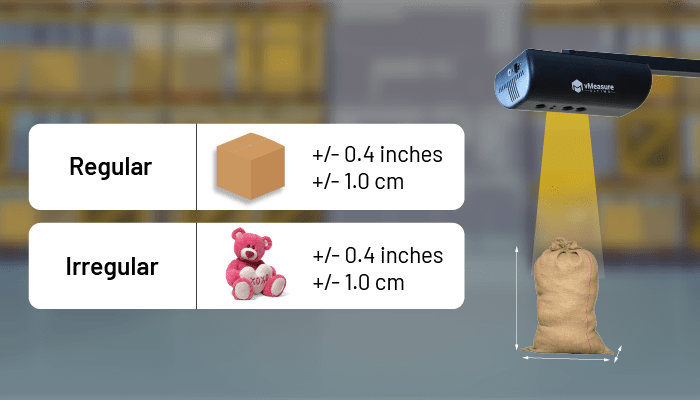

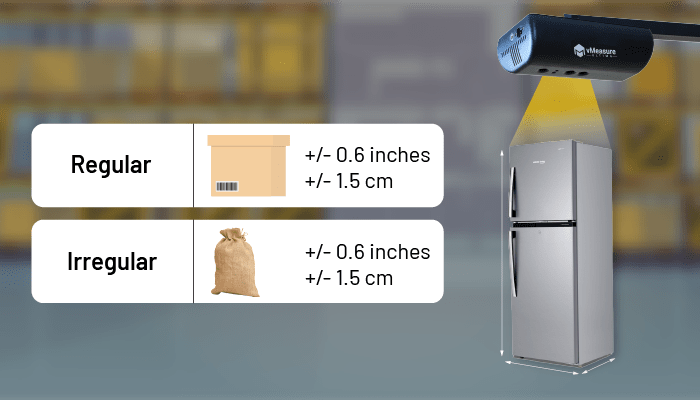

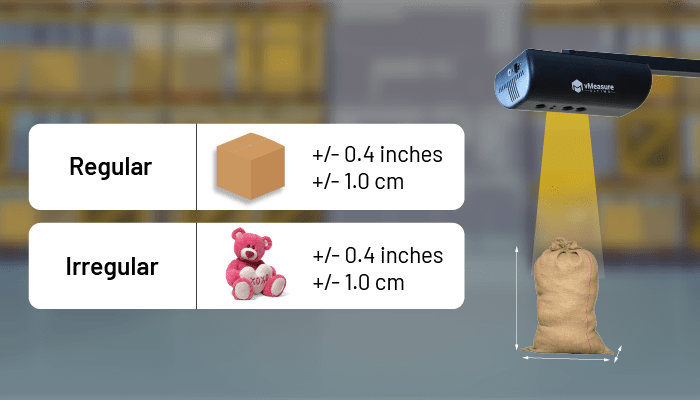

- Measuring Accuracy

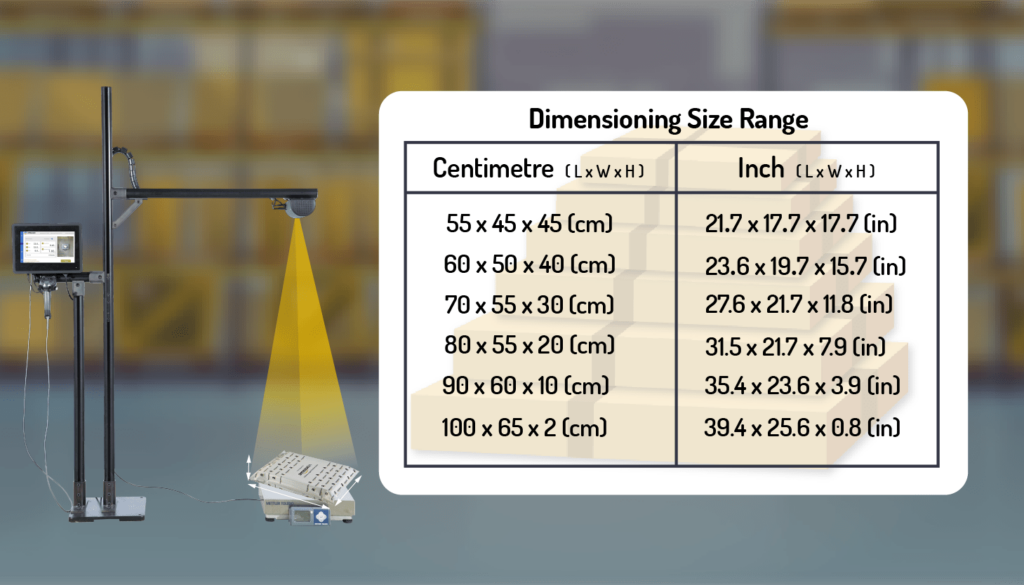

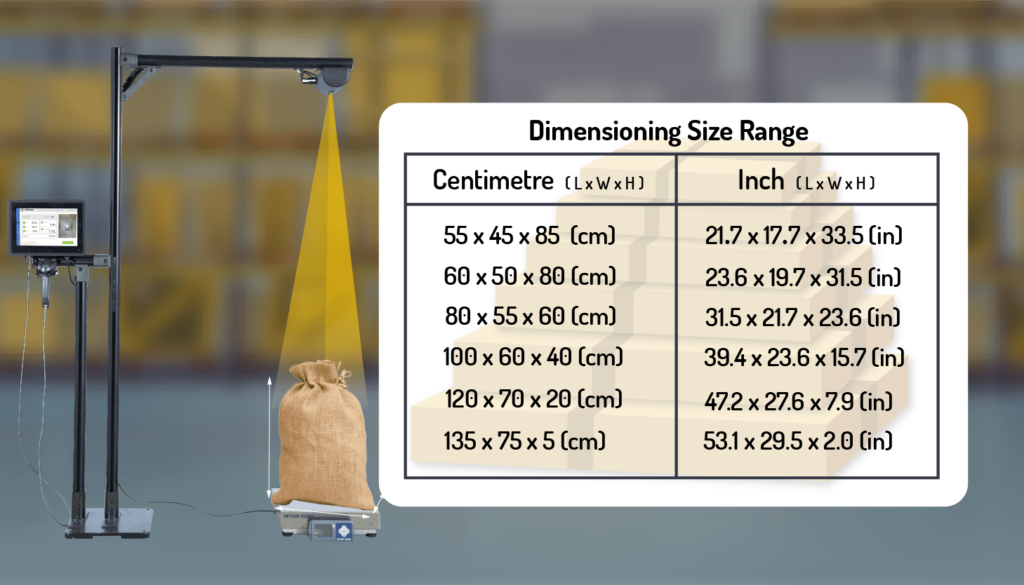

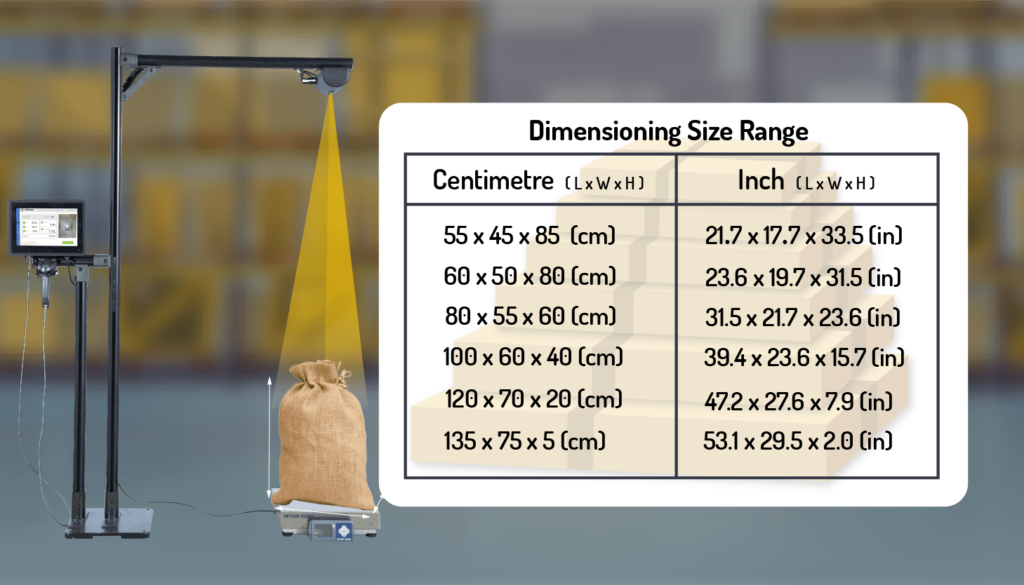

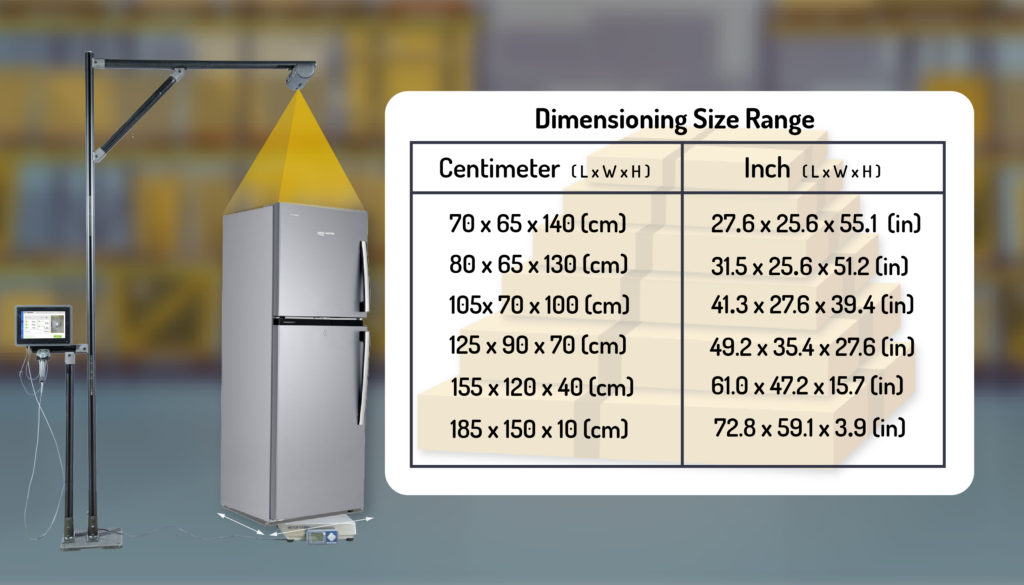

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

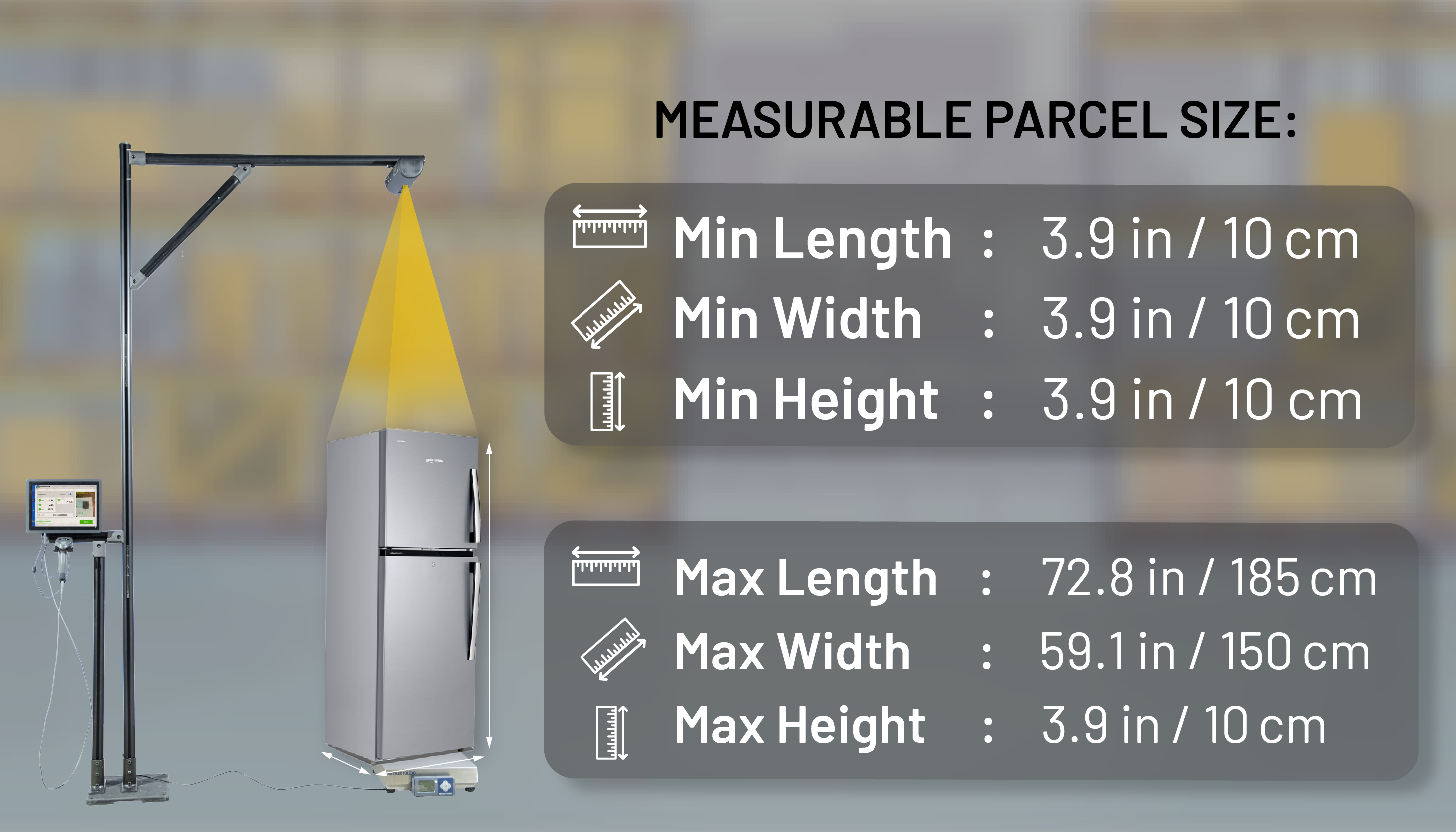

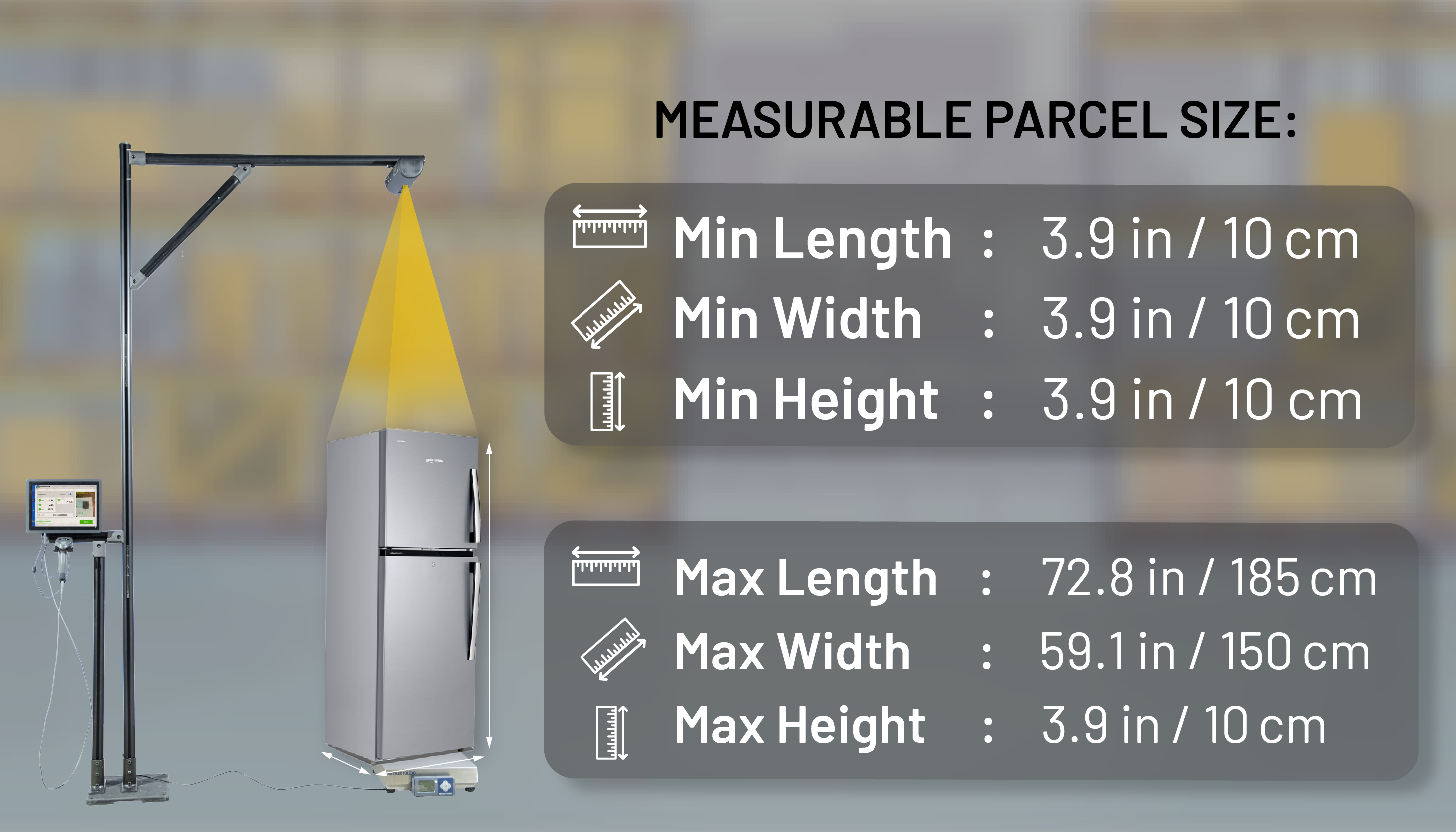

- Min and Max Measurable Size

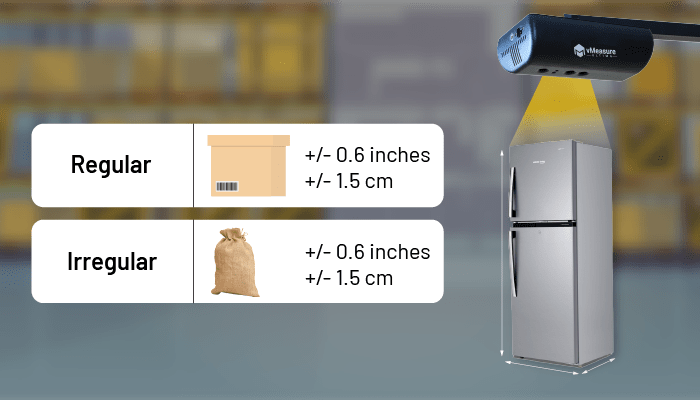

- Measuring Accuracy

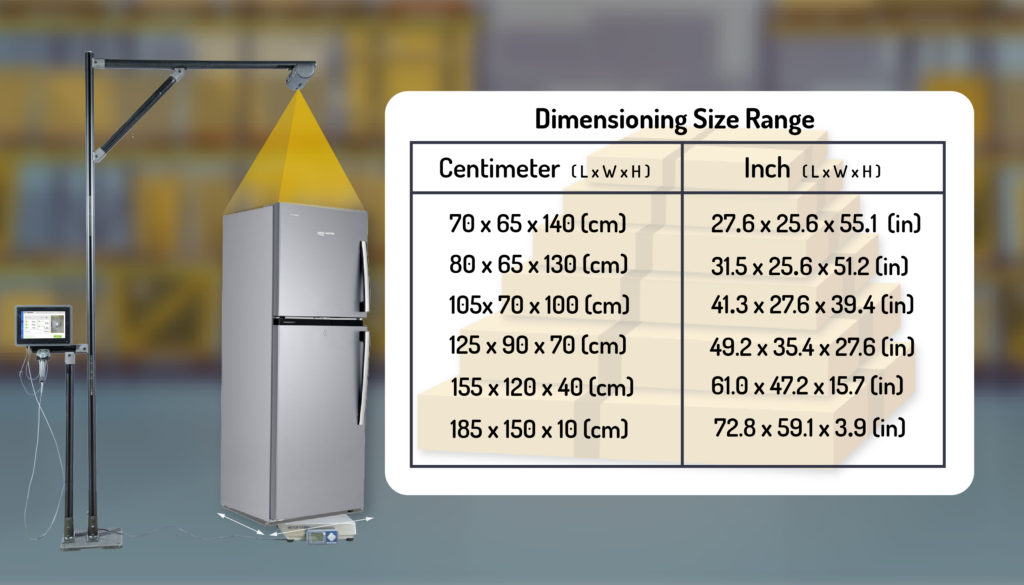

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods