How did a Vehicle parts distributor save on Shipping with the vMeasure Dimensioner machine?

Industry

Product

Process

Use case

Integration

Case Study Summary

The client is a vehicle parts distributor for premium and performance cars. They deployed vMeasure at the receiving station to dimension vehicle parts as they entered the warehouse.

vMeasure Dimensioner machine provided a special QR code in its touch screen, which the mobile app-based WMS system used to capture data through the QR code decoding facility. The dimensioning data was then stored in the client’s item master data.

The client can now create the right packaging for the vehicle parts based on the accurate dimensions and maintain a clean item master in their WMS system.

Problems faced by the Client

- Business Problems

- Logistics Problems

- IT Problems

Wrong-sized packages were used for different-sized SKUs because of incorrect dimensions.

Because of wrong packaging, the calibration of the high-performance motor parts was damaged. This led to longer repair times for their customers (Auto Service centers).

Wrong dimensions, especially on similar parts, lead to bad item master data.

Because of wrong packaging, the customer must do increased quality checks at the shipping station leading to decreased packing efficiency

Wrong item master data led to wrong dimensions being sent for packaging, and as a result, oversized boxes increased shipping charges.

The staff had to do extra quality control activities at the outbound leading to lower throughput at the packaging station.

While the current mobile-enabled WMS was perfectly adequate for their operations, it lacked integration capabilities.

The IT team could not provide the resource to handle complex integration for the logistics team.

The client’s WMS were fully mobile on their tablets.

Wrong-sized packages were used for different-sized SKUs because of incorrect dimensions.

Because of wrong packaging, the calibration of the high-performance motor parts was damaged. This led to longer repair times for their customers (Auto Service centers).

Wrong dimensions, especially on similar parts, lead to bad item master data.

Because of wrong packaging, the customer must do increased quality checks at the shipping station leading to decreased packing efficiency

Wrong item master data led to wrong dimensions being sent for packaging, and as a result, oversized boxes increased shipping charges.

The staff had to do extra quality control activities at the outbound leading to lower throughput at the packaging station.

While the current mobile-enabled WMS was perfectly adequate for their operations, it lacked integration capabilities.

The IT team could not provide the resource to handle complex integration for the logistics team.

The client’s WMS were fully mobile on their tablets.

Why did the customer choose vMeasure dimensioner machine to solve

the above logistics problems?

- Dimensioning Capability

- Software Integration

- On-Screen Customization

- Physical Characteristics

vMeasure Dimensioner covers all the major SKU sizes which need to be dimensioned

The accuracy and repeatability metrics were in-line with the Operations teams' expectation

Provided a workaround for the integration with the warehouse management system. Also, vMeasure was integrated with the client’s own weighing scale

Provided a scannable QR code that produced data in a WMS friendly format so its camera system could read, decipher, and upload into the item master

Customized the screen to make the QR code visible

The QR code was embedded with all the data required by the WMS in the prescribed format

vMeasure Dimensioner was small and compact

The difference was as much as 60% from vMeasure’s next economical option

vMeasure Dimensioner covers all the major SKU sizes which need to be dimensioned

The accuracy and repeatability metrics were in-line with the Operations teams' expectation

Provided a workaround for the integration with the warehouse management system. Also, vMeasure was integrated with the client’s own weighing scale

Provided a scannable QR code that produced data in a WMS friendly format so its camera system could read, decipher, and upload into the item master

Customized the screen to make the QR code visible

The QR code was embedded with all the data required by the WMS in the prescribed format

vMeasure Dimensioner was small and compact

The difference was as much as 60% from vMeasure’s next economical option

The vMeasure Dimensioning Solution

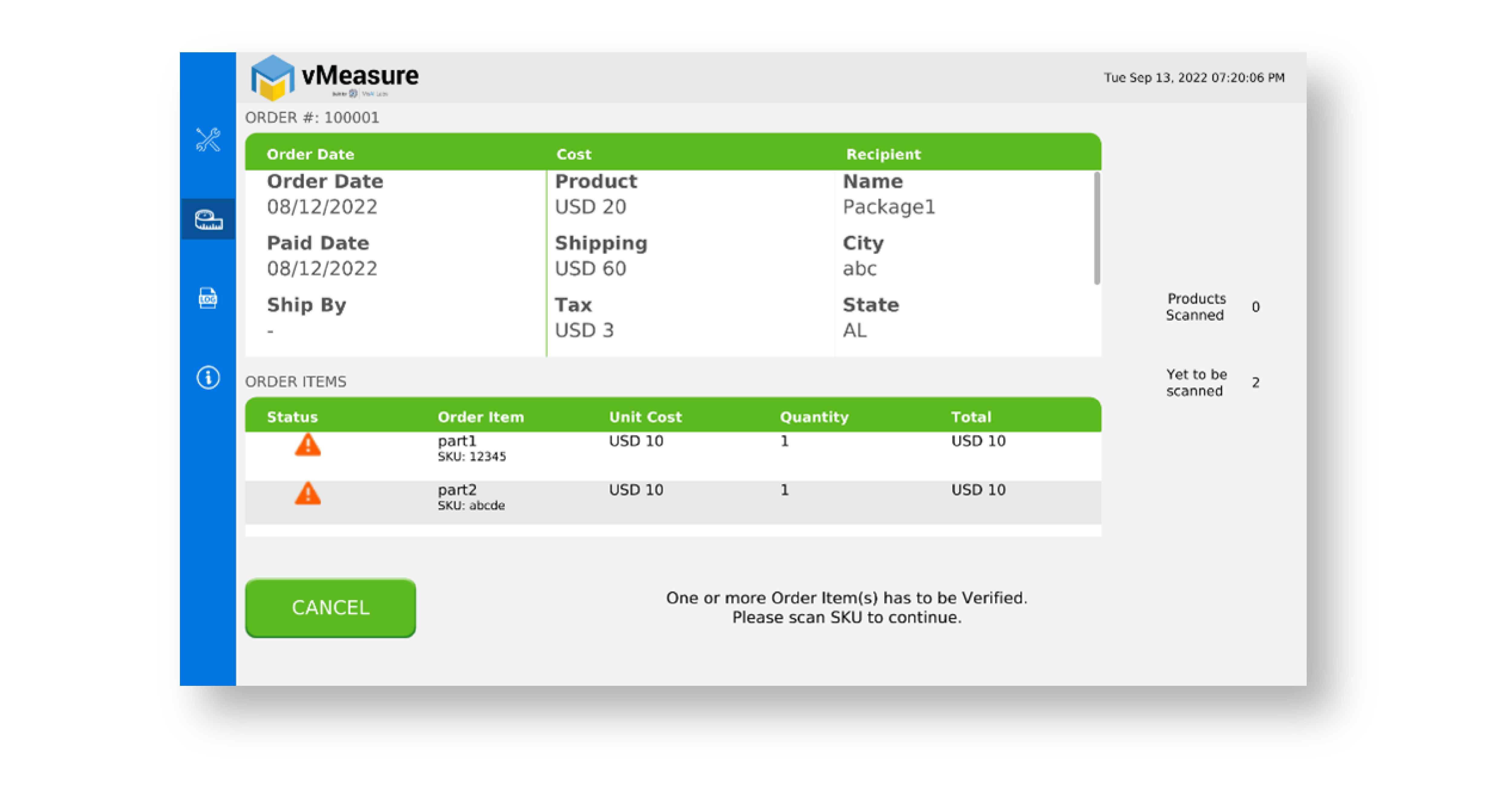

- The order details, along with the SKUs to be packed for the order, are displayed.

- The warehouse associate then scans the individual FNSKU to verify.

- Once all the items are verified using the FNSKU, the warehouse associate then packs the order and places the package on the vMeasure system.

- The warehouse associate scans the confirmation barcode to trigger the measurement on the vMeasure system.

- Once the measurement is triggered, the vMeasure system automatically dimensions the package and updates the corresponding data to Ship-Station

- The vMeasure system returns to the order ID scan screen automatically once the data upload to ShipStation is complete.

Benefits accrued by the client by using vMeasure dimensioner machine

- Business

- Operational

- Administrative

Lower carbon emissions because of reduced shipping volume

Improved customer experience as the products went into right-size packages and the items were not damaged

Verify the quality of the inbound SKU through SKU photograph at inbound stage

The company could see the variety of SKU sizes which helped them optimize packaging and lower costs

Reduced risk of using inaccurate data for shipping or data management entered manually

Increased Parcel throughput by shipping more orders

Simplify the process of choosing each carton faster with accurate SKU measurements

Reduced the manual steps for dimensioning from 6 to 2, thereby increasing workers’ productivity

The admin team gained access to a single source of truth for all the SKU measurements by creating accurate item master data

Improved the item master data as the WMS received accurate item DIMs

Reduced the risk of over-charging customers

Enabled better quality check during the outbound as the parcel was photographed using vMeasure

What makes vMeasure the only static parcel dimensioner

capable of solving your needs?

- Small SKU Mode

- All Parcel Mode

- White Goods Mode

- Mount Height

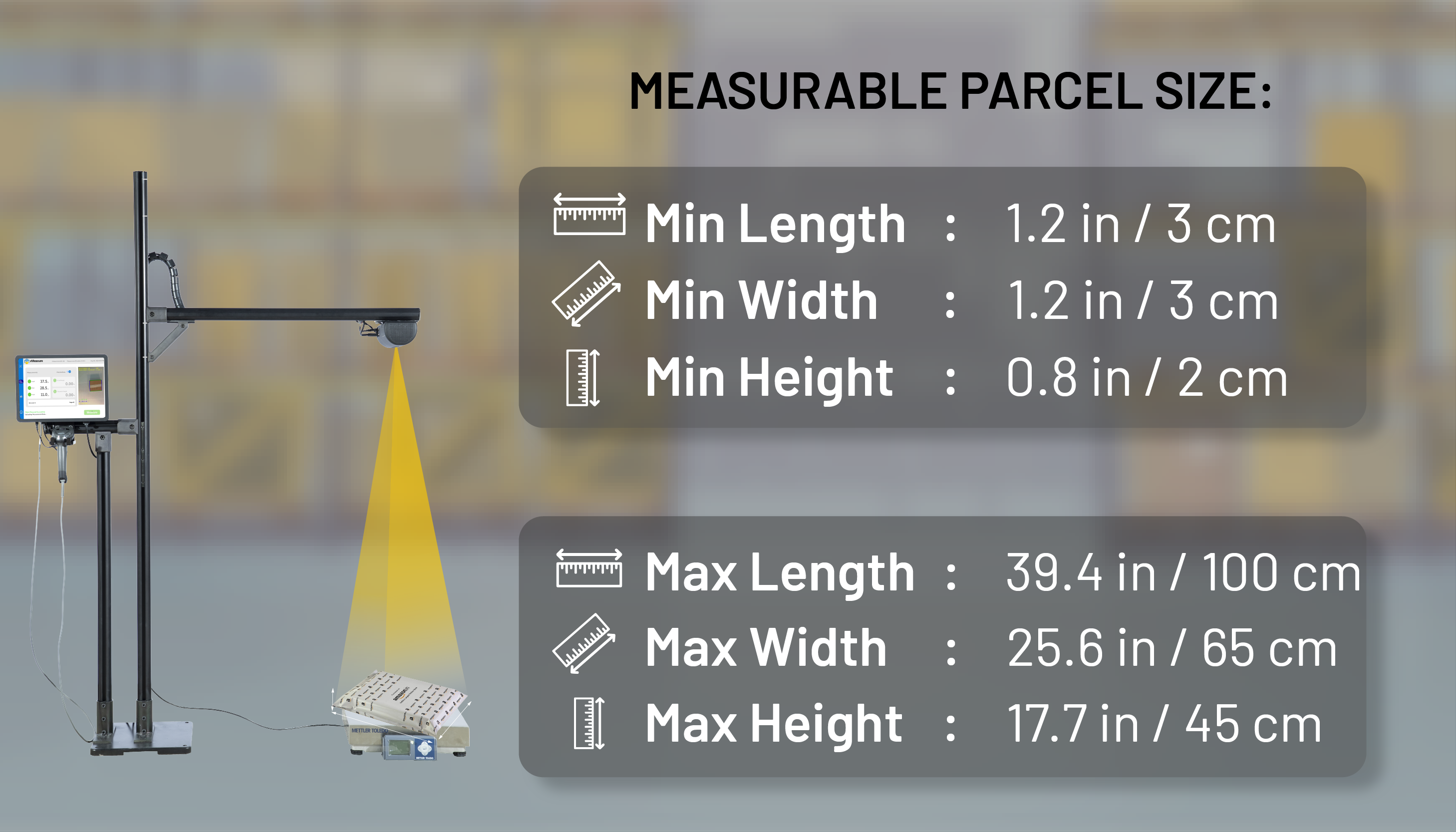

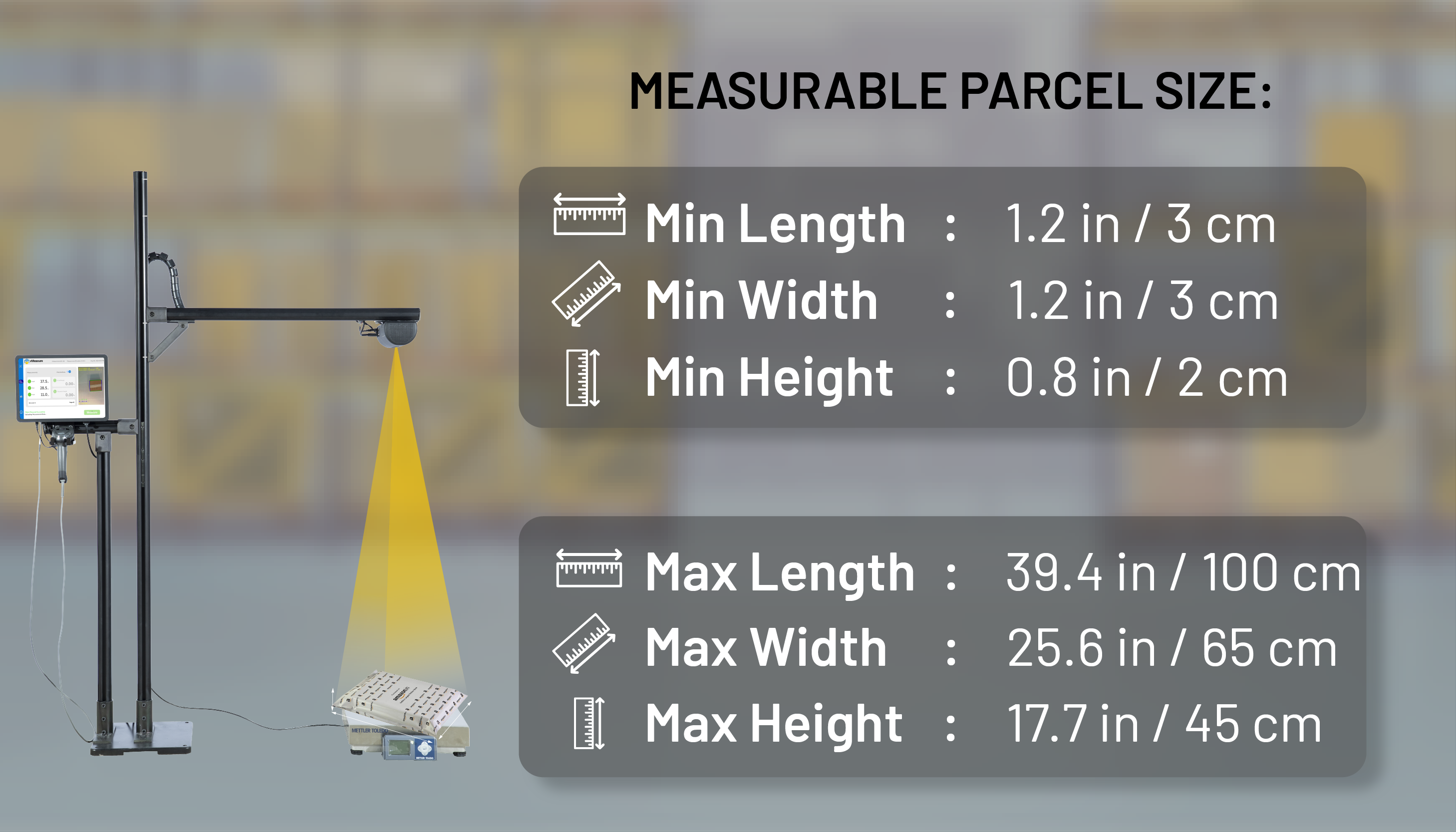

- Min and Max Measurable Size

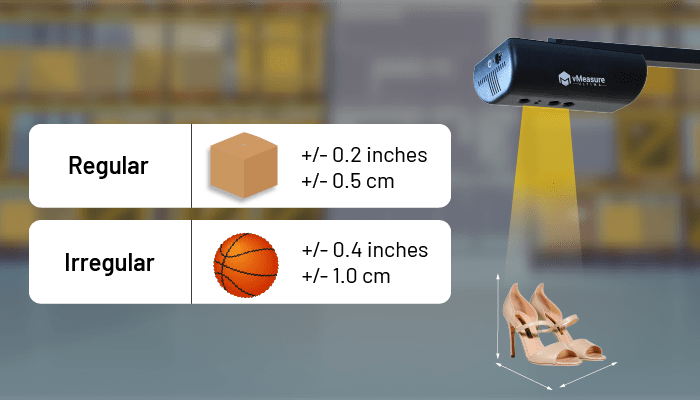

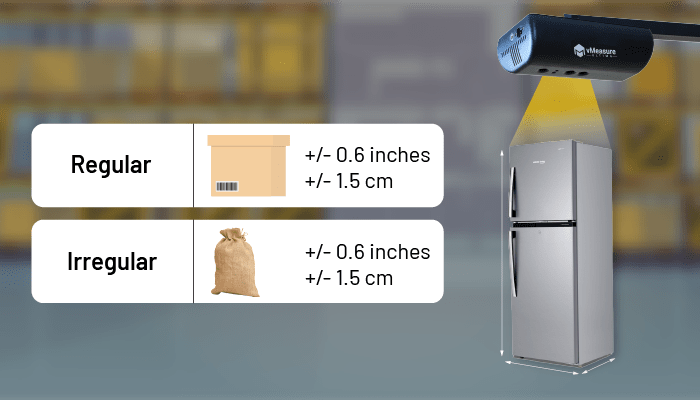

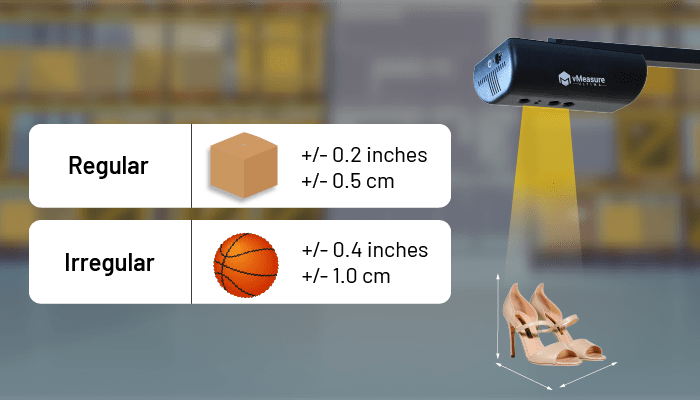

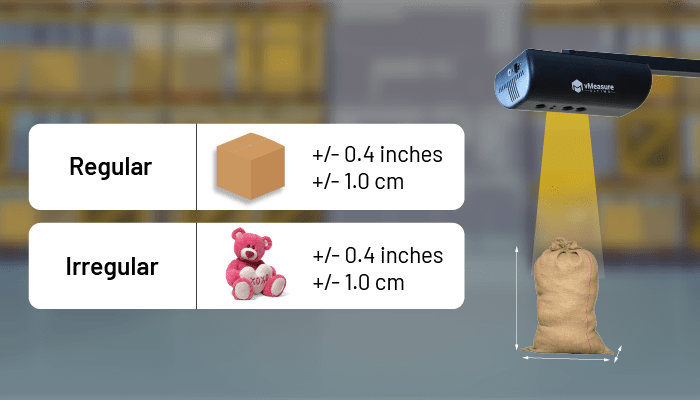

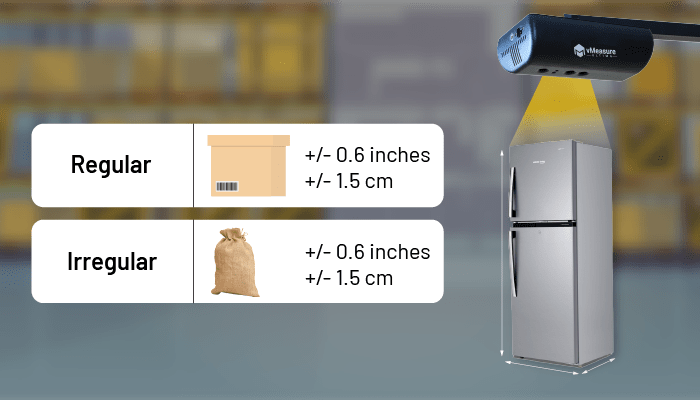

- Measuring Accuracy

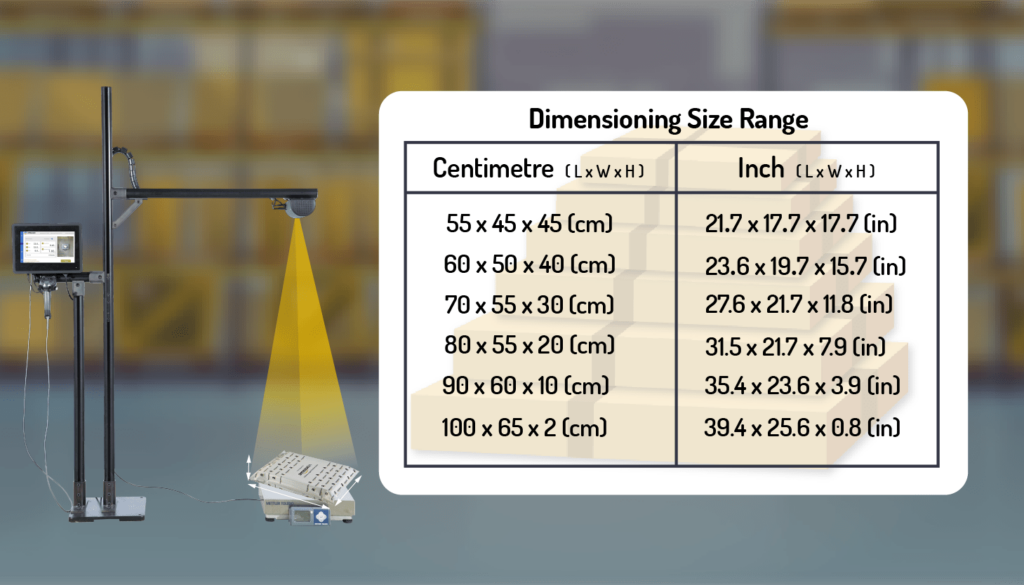

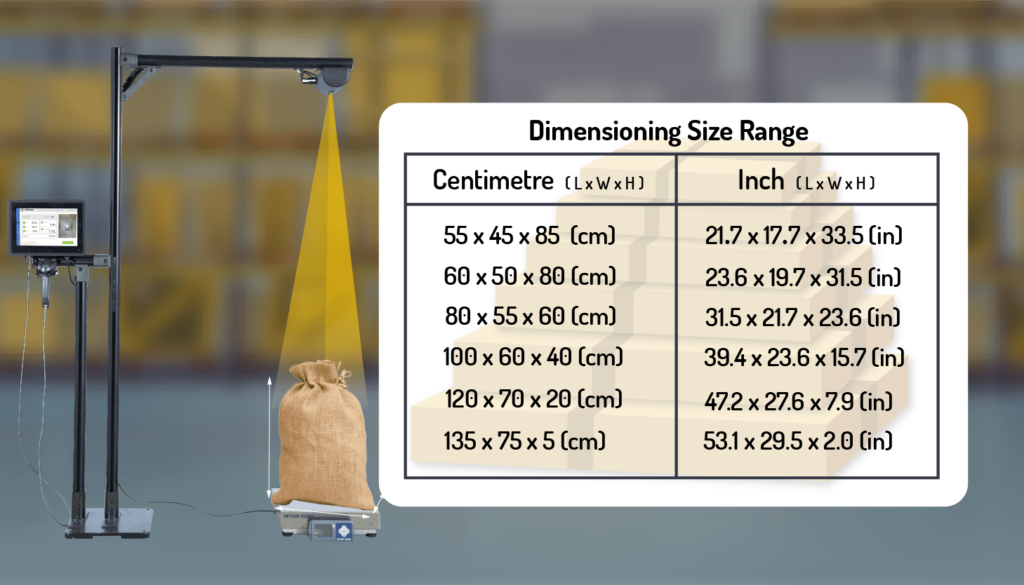

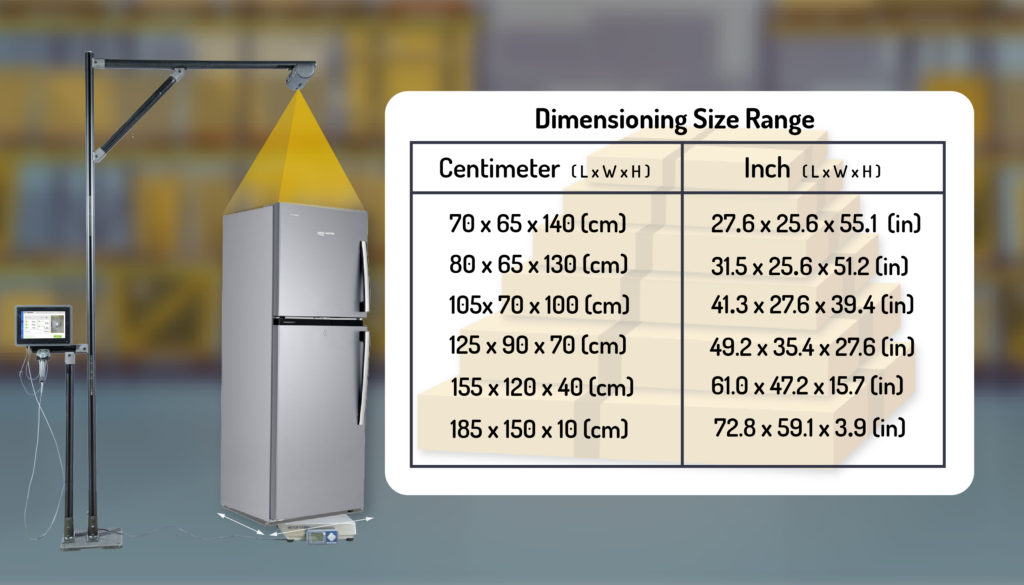

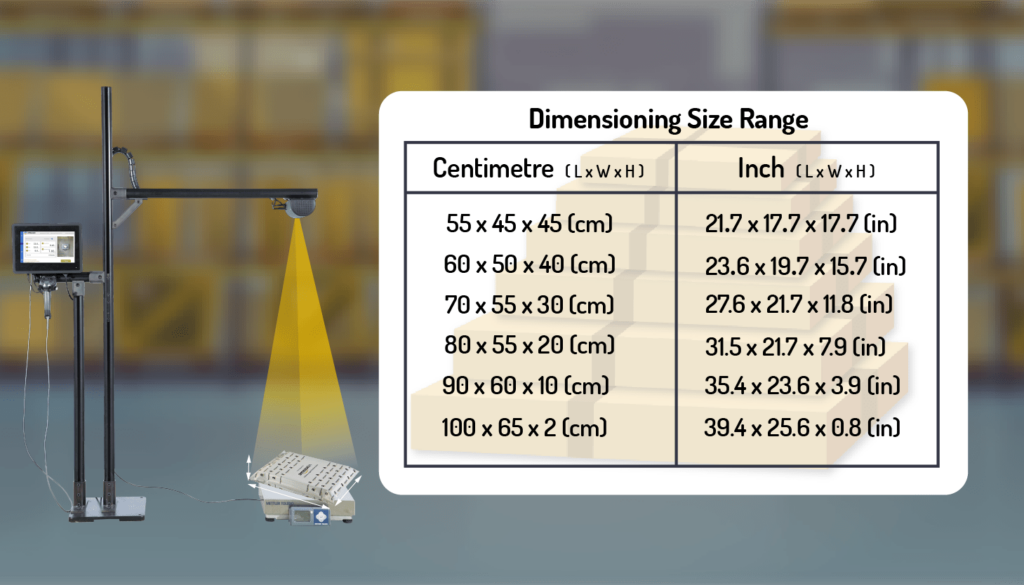

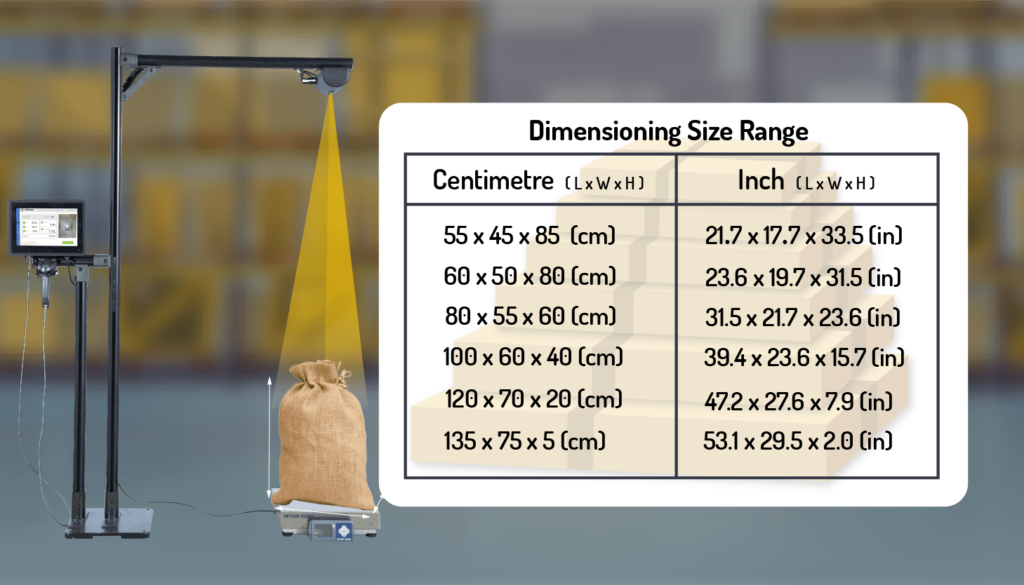

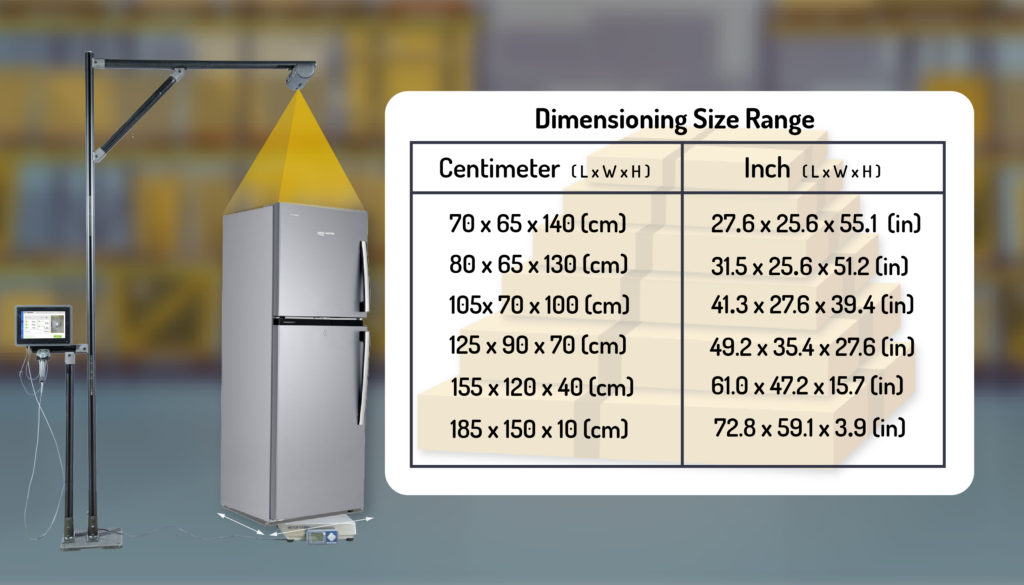

- Dimensioning Size Range

- Additional Data Capture

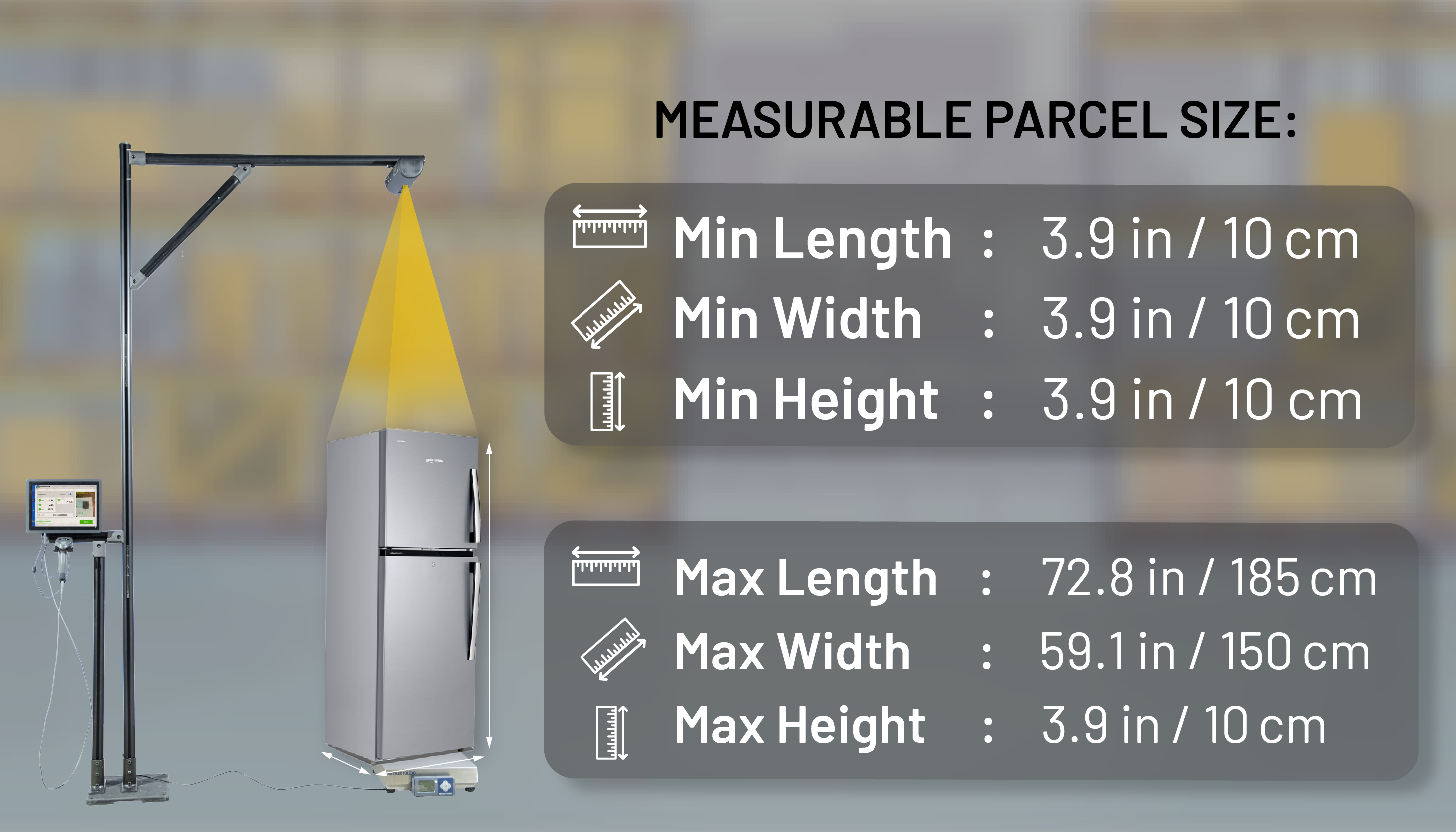

- Mount Height

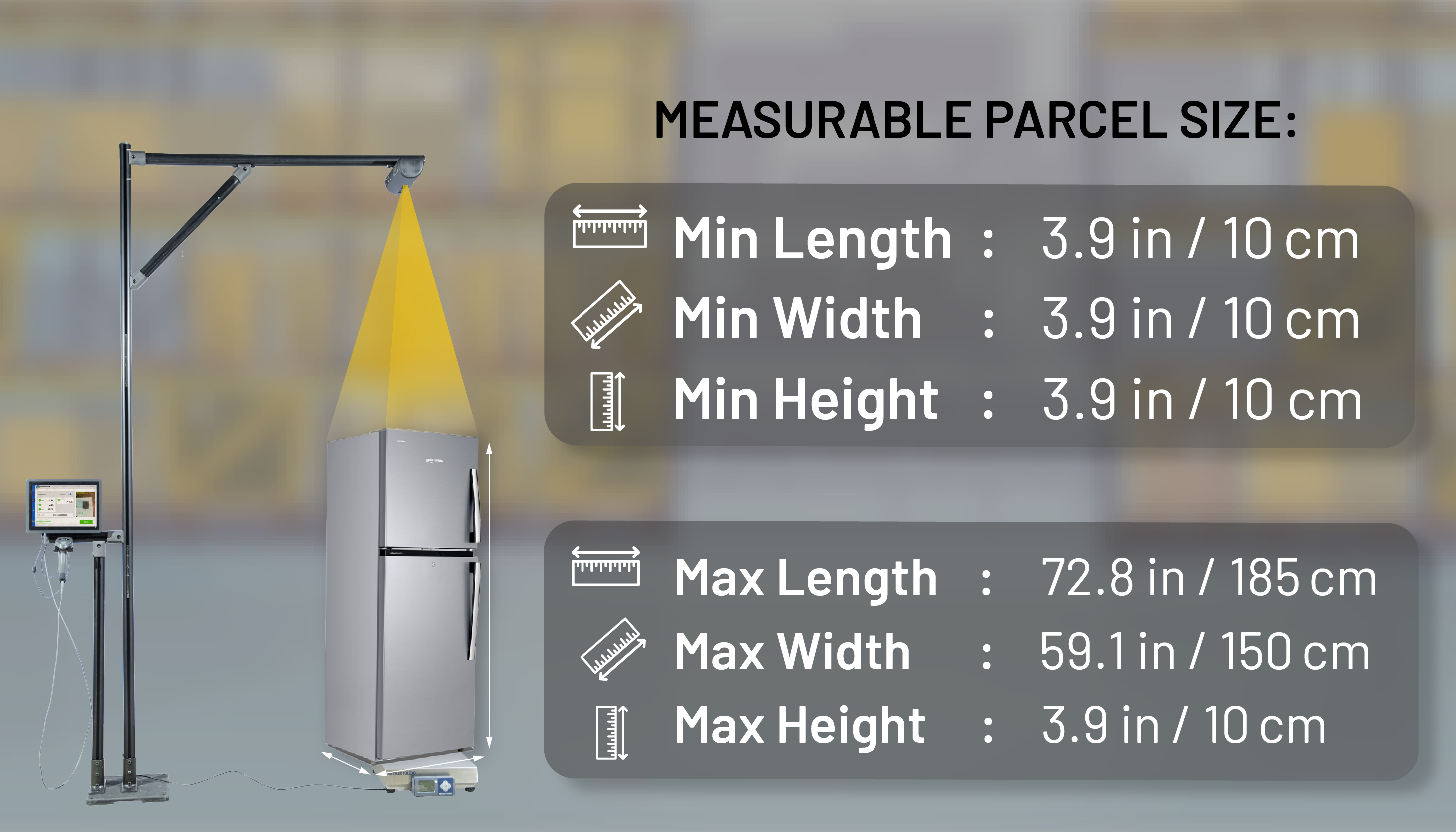

- Min and Max Measurable Size

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Mount Height

- Min and Max Measurable Size

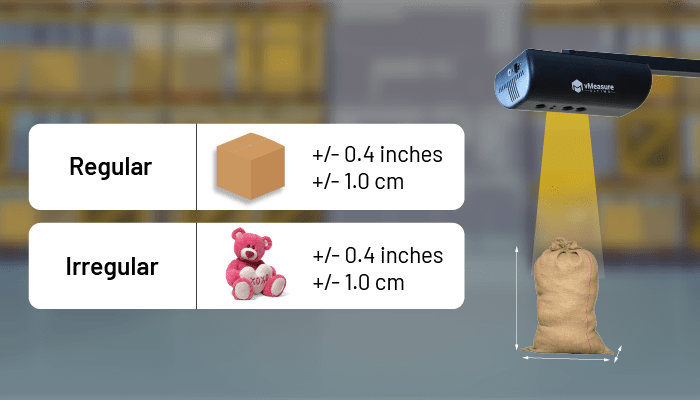

- Measuring Accuracy

- Dimensioning Size Range

- Additional Data Capture

- Small SKU

- All Parcel

- White Goods