Freight Audits aren’t occasional anymore.

They’re showing up in the middle of your week, right when the docks are full and staff are stretched.

NMFC Docket 2025-1 has shifted the balance: the initial measurement and the data you submit can be challenged at any time. Carriers now expect every shipper to prove that their records are accurate and verifiable.

This isn’t about preparing for a rare investigation. It’s about operating in a world where audit readiness is part of the daily shipping flow. If audit readiness is now part of daily shipping, the next step is understanding what changed in Docket 2025-1 to make audits a constant pressure point.

How does Docket 2025-1 change the freight audit?

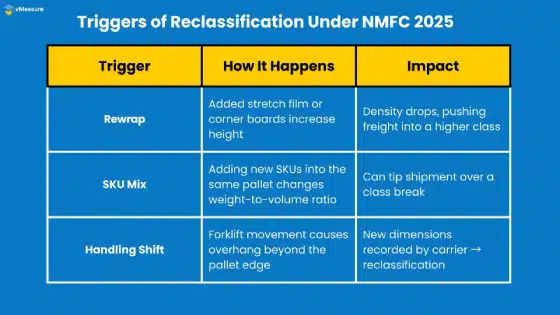

The release of NMFC 2025-1 wasn’t just a simple update. By collapsing thousands of commodity codes into density-based rules, it reset how freight costs are determined. For shippers, that shift means the first scan you provide is no longer optional paperwork; it’s the anchor point carriers will validate against. If your measurement is off or your proof is missing, you’re exposed to disputes that go straight to your bottom line.

Audit pressure is no longer a possibility; it’s become part of daily operations. And because cost is tied directly to that first scan, carriers aren’t waiting for annual or quarterly reconciliations; they’re issuing mid-cycle audit requests that cut into your week.

Why are mid-cycle audits the real disruptor?

For most shippers, the real pain isn’t a once-a-year audit; it’s when a carrier demands proof in the middle of a busy week. While your dock is at full capacity, finance teams are forced to drop everything to locate shipment records. This disruption bleeds into service levels, reporting deadlines, and even carrier relationships.

Freight audit readiness isn’t about having a binder of records somewhere; it’s about proving accuracy instantly, without slowing operations. If the disruption is unavoidable, the next step is making audit readiness the baseline, something baked into every shipment before it leaves the dock.

Why is “audit readiness” the new baseline?

In the past, compliance was measured in terms of paperwork accuracy. Now, carriers expect verifiable, accurate data that can withstand audit review. This isn’t about waiting to respond when a reclass notice arrives. It’s about ensuring from day one that your measurement, weight, and class records are airtight.

Freight Audit readiness means:

- Your first scan holds up against carrier verification.

- Your measurement source is trusted, not just convenient.

- Your records are instantly retrievable, not scattered across systems.

When those conditions are met, audits stop being reactive firefights and start becoming non-events. Automated pallet dimensioning systems are the tools that make this standard repeatable.

But knowing the baseline is only part of the answer. To stay compliant, shippers also need a way to prove readiness without slipping back into old gaps.

How do you prove audit readiness without repeating past mistakes?

Instead of waiting for the next reclass to expose a gap, shippers need a forward-looking approach. The question isn’t “can we react?” but “can we prevent?”

- Alignment with carrier records: Do your first scans match what carriers enter, down to fractions of an inch?

- Single source of measurement truth: Can you point to one verified system, or are you still juggling spreadsheets, WMS logs, and manual notes?

- Speed of retrieval: When finance or a carrier asks for proof, is it instantly available, or do you spend hours stitching files together?

These aren’t box-checking exercises; they are signals of audit readiness. Shippers who can answer “yes” to each are positioned to defend their costs before disputes ever start. But when those answers are missing, the fallout isn’t limited to penalties; it shows up in hidden costs that quietly drain profit and credibility over time.

What are the hidden costs of being unprepared?

Shippers often calculate penalties and rebill, but they miss the silent costs:

- Opportunity cost: Carriers hesitate to offer favorable terms if your records are questionable.

- Team cost: Finance and ops waste hours reconstructing files instead of managing freight.

- Reputation cost: Getting flagged as “high risk” affects negotiations long after the audit.

These hidden costs are why audit readiness pays for itself. They’re not just penalties on paper, but long-term risks to margin and trust. Avoiding them means closing every gap before the carrier does, and that’s where automated pallet dimensioning systems move from being a tool to being the backbone of audit defence.

What role do pallet dimensioning systems play?

Manual tapes and records can no longer carry the weight of a freight audit. They may work in small, controlled settings, but they fail under the volume, accuracy, and verifiability required under NMFC changes. Automated pallet dimensioners eliminate that fragility.

They capture accurate dimensions at the dock, integrate them directly into your WMS or TMS, and tag each record to the shipment ID. When auditors ask for proof, you don’t dig through old files; you export a verified record that aligns with the carrier’s own system. That is how audit readiness scales.

The table below highlights the most common audit readiness gaps and how automation closes them, turning weak links that once triggered disputes into verifiable proof.

But proving the value of automation on paper isn’t enough. The real advantage comes when shippers embed it into their daily dock flow. That’s why the next step isn’t just knowing automation works, it’s building it into your process before the next audit notice arrives.

What should shippers do now to avoid audit surprises?

Treat freight audit readiness as a standing requirement, not a crisis plan. That means investing in upstream controls instead of back-end firefighting:

- Automate measurement at the dock so every shipment starts with verifiable data.

- Integrate systems so measurement, weight, and class flow together instead of living in silos.

- Set retrieval SLAs internally so proof is always a click away.

Shippers who act now won’t just avoid penalties, they’ll negotiate better contracts, reduce disputes, and restore predictability to freight costs. That’s why audit readiness can’t sit on a checklist; it has to live inside your daily dock flow.

With automated pallet dimensioners like vMeasure, every first scan becomes proof that’s already ready when the carrier asks. Not next week, not after hours of digging, right when it counts. That’s how you stay audit-ready in a post-Docket 2025-1 world, and the shippers who make it standard today will be the ones setting the pace tomorrow.