Dimensioners

The Ultimate Guide

To Automated Dimensioners

The logistics industry is always under insurmountable pressure because of customer expectations. With 60% of customers saying same-day or next-day delivery having significant influence on their purchase decision, the need for speed is perpetually increasing. However, the logistics industry is able to keep up and satisfy customer’s fast shipping demands through an array of modern solutions. An automated dimensioner is one of them.

The robust dimensioning system has simplified shipping and removed the irrationality behind charging less for the actual weight of a full truckload of feathers and more for a truckload of bricks.

Table of Contents

What is an automated dimensioner and how does it work?

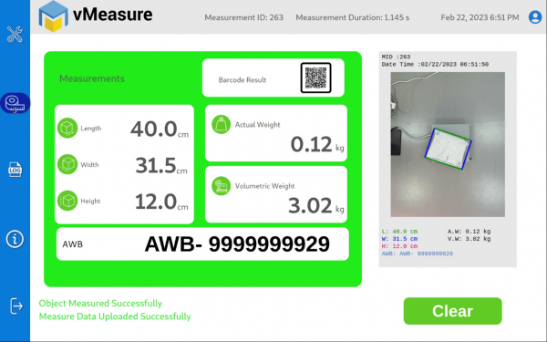

There are many types of dimensioner based on their mode of operation such as laser-based dimensioners, computer-vision based dimensioners, and infrared dimensioning systems.

Benefits of using an automated dimensioning system

Ever since automated dimensioners took over the logistics industry, it has been smooth sailing for every player in the industry. However, many warehouses still inadvertently use manual dimensioning process and do not realize the multi-fold benefits of using an automation. check out dimensional weighing systems

Increased Productivity

For instance, vMeasure reduced the time taken for bill reconciliations from 7 days to 20 minutes for one of our customers. Check out the full case study here.

Reduced shipping costs

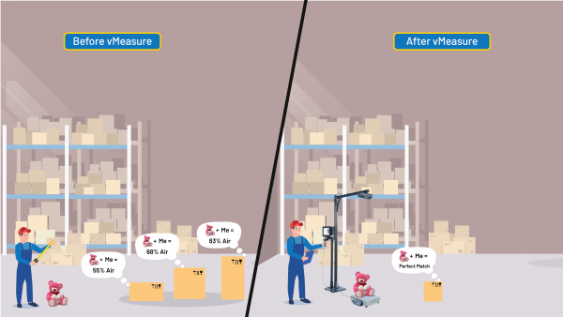

Improved warehouse space utilization

Efficient Slotting

Optimized Packaging

Truckload capacity planning

Who needs an automated dimensioner and why?

Warehouses

- Warehouse space optimization.

- Improve labour utilization.

- Automate data capture and transfer.

- Improve slotting and put away.

- Efficient picking and packing.

- Verify inbound and outbound SKU quality.

- Prevent SKU damage.

eCommerce Order fulfillment centers

- Increase productivity at the packing station.

- Handle high volumes of order.

- Improve carrier negotiation.

- Protect against damage claims.

- Increase order dispatch accuracy.

- Improve throughput rate.

- Handle a wide variety of SKU shape and size.

- Enhance picking and packing speed.

- Improved quality control.

Carriers

- Optimize packaging.

- Plan delivery routes.

- Optimize loading time.

- Maximize truck’s capacity and improve load balancing.

- Improve freight billing accuracy.

- Eliminate rebills and reweighs.

- Improve data transparency with shippers.

- Comply with weight regulations.

Shippers

- Determine right packing for the order.

- Provide accurate dimensions to the carrier.

- Negotiate better deals and rates.

- Reduce shipping charges.

- Decrease time spent on billing disputes.

- Improve revenue recovery.

- Enhance packaging.

- Increase parcel throughput.

What should you look for while buying a dimensioner?

What should you look for while buying a dimensioner?

How accurate are the measurements?

What is the use-case?

How CV-based dimensioners differ from laser-based dimensioners?

What is the use-case?

Versatility

Dimension all types of SKU in <1 Sec

Integration capabilities

Use Cases

Inbound Use Cases

- warehouse space optimization

- Cartonization

- SKU Master Data

- Slotting and Putaway

Check out how a fulfillment center improve slotting using vMeasure Automated Dimensioning System.

Outbound Use Cases

- Maximizing truck capacity

- Accurate dimensions for carrier billing

- SKU image capture for parcel insurance

- Zero-air packaging