What do you think you’ll take away from this episode?

Relevant links:

Podcast Transcript:

Now let’s see the six ways the logistics providers join forces with dimensioning specialists to transform their warehouse capabilities.

First way: Automate the dimensioning process

The conventional dimensioning process is time-consuming, error-prone, and workforce intensive, resulting in delays and concealed damages, dramatically affecting productivity.

Automating the dimensioning process assists in resourceful slotting, cartonization, and quality checks.

Also, it simplifies warehouse functionalities, reduces carbon footprint and wastage, thereby reducing operational costs and overheads.

Second way: Enabling better decision-making

Dimensioning specialists help logistics providers make better data-driven decisions in the warehouse.

Using the inputs’ insights, logistics firms can make optimal decisions in space allocations and quality corrections.

Third way: Determine warehouse rents

Dimensioning experts used automated systems to determine an item’s exact value and volume to arrive at a fair rent or leasing arrangement.

Fourth way: Increase throughput

Dimensioning experts help logistics firms optimize warehouse workflows by designing automation systems and machinery upgrades based on the size and weight of the SKUs.

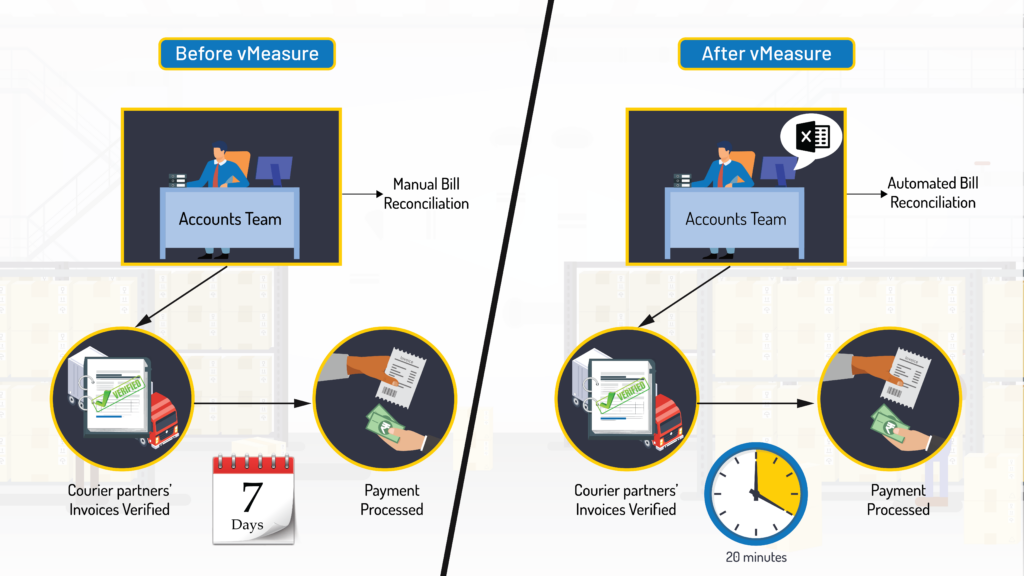

Fifth way: Enhancing revenue recovery

Due to faulty freight charges, incorrect packing damages, product returns, refunds, and replacements, logistics firms struggle with financial losses.

With the precise dimensioning measurements, Dimensioning experts help logistic companies to identify and rectify discrepancies, arrive at accurate costs, plan effective resource utilization, and recover the revenue lost during the manual measurement days.

Legacy receiving systems are a substantial bottleneck in inbound logistics.

The incoming freight can be measured, captured, sorted, packed, and sent to its recommended location via AI-led material handling devices by deploying automated parcel dimensioning systems.

This is Alphonse, the Product Manager of VisAI Labs, And that’s the logistics insight for today.