What do you think you’ll take away from this episode?

Relevant links:

Podcast Transcript:

Meanwhile, because the job supposed to be completed, both significant and minor warehouse issues may not always receive the attention they need.

Well, Let’s look at the top 5 warehouse problems and remedies to consider when boosting warehouse performance.

The First is Inaccurate inventory

There are always ways to reduce surplus inventory and increase sales, no matter how long your company has been in operation.

Broken equipment or expired stock, for example, might make the supply chain more challenging.

Whether it’s keeping track of purchase orders or pricing new products, each piece of the inventory management puzzle has its own set of challenges to overcome.

With the right inventory system, you can significantly keep track of inbound and outbound sales in your warehouse.

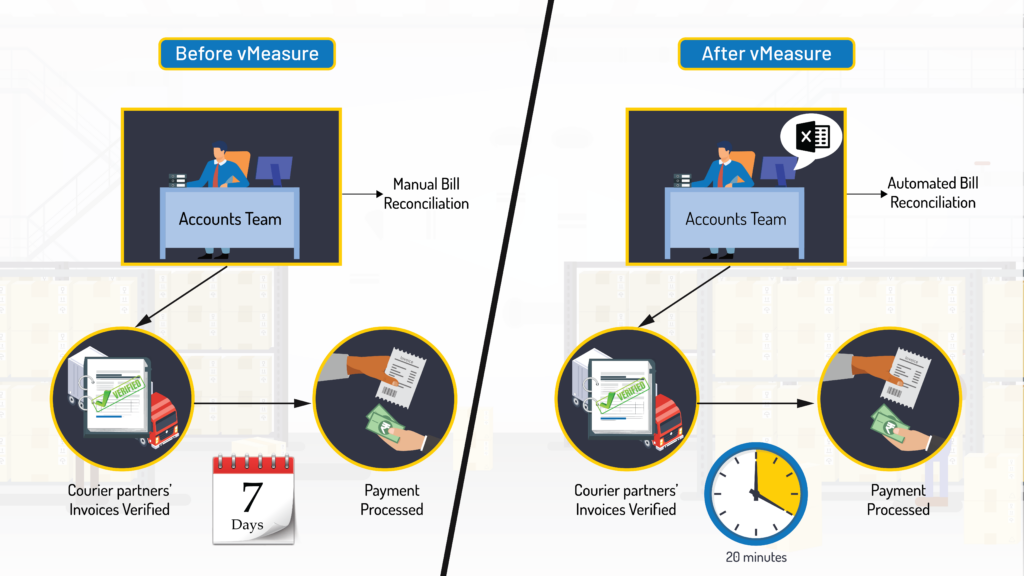

The Second is an iterative task

The most common pitfall in the warehouse is handling redundant warehouse activities, which consumes more time.

For this, automation can be the only key.

By automating the iterative task, we can assign the other high-priority tasks to the warehouse associates.

The Third is space utilisation

With the advent of eCommerce, attaining space utilisation has taken on added urgency.

For this, we need to deploy the high-density automated storage and retrieval system to bump up space utilisation significantly.

The Fourth Is Increased labour cost

Distribution and fulfilment centre executives are under growing pressure to cut costs while boosting service standards.

Picking remains a largely manual operation for the time being, while new methods are being developed. Consider how pallet flow systems and AS/RS technologies can help you increase pick rates.

The Last is dodging product damage

In a warehouse, products might be harmed for a variety of causes.

This is sometimes discovered during the picking process.

Product may be moved more carefully with modern racking and pallet flow systems than with earlier technologies.

Managing a warehouse is a difficult task.

You need to keep track of every moment.

This is Alphonse, the Product Manager of VisAI Labs, And that’s the logistics insight for today.