Many warehouse owners hurry to deliver things to clients’ doorsteps as the number of online purchases continues to rise. When most people think of warehouse automation, they picture it as something that will happen in the far future. Automation technologies can help businesses become more efficient, accurate, and productive while also cutting costs.

What do you think you’ll take away from this episode?

In this episode, we look at how warehouses and logistics centres implement AI-driven technology to increase profits.

Relevant links:

Podcast Transcript:

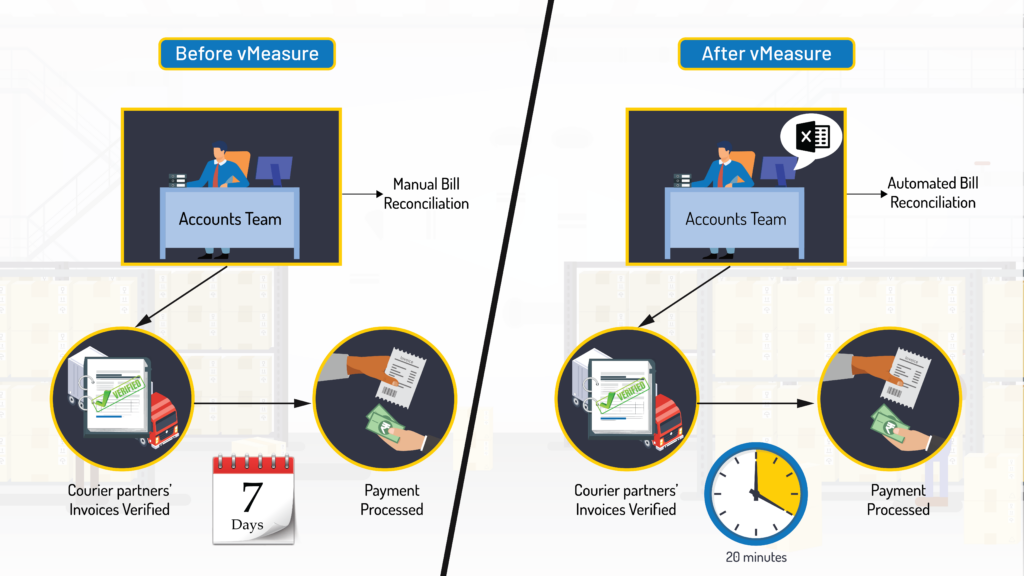

Innovation despite the emergence of these groundbreaking digital applications they still relied on manual touchpoints and time-consuming processes, and outdated protocols, lack of automation and innovation greatly impacted the efficiency of critical jobs such as inventory, space allocation, dimensioning packaging as well as your inbound and outbound logistics conventional processes and these measurements increase complexities leading to avoidable costs and errors.

Today though supply chain and logistics businesses have caught up with the indispensable digital transformation, they realize the importance of automation and AI-led warehousing technology in increasing their profitability and reducing cost.

It is very important to note that the smallest technology nudge can accelerate the entire supply chain journey from storage to shipment automation. Here boosts the security flexibility and efficiency of your logistics operations.

But despite all this technology adoption dimension, next remains the biggest challenge that logistics businesses face today. Warehouses grapple with incorrect measurements, transposition errors, increased costs, and wasting time due to manual dimensioning.

Choosing the right automated dimensioning framework plays a critical role in maximizing the value of the logistics capability. It drives shipping profitability, eliminates cost discrepancies, speeds up order fulfillment, and optimizes space allocation whilst helping you in capacity planning slotting and quality control.

The right automated dimensional framework coupled with the right warehouse management system and ERP can help you turn your equipement into a profitable center.

And that, my dear friends, is the logistics insight for today.

Thank you!